Synthesis method of 1-methyl-4-methyl sulfonyl benzene

A technology of methylsulfonylbenzene and a synthesis method, which is applied in chemical instruments and methods, chemical methods for reacting liquids and gaseous media, and preparation of organic compounds, etc. to prevent material blockage and enhance the gas-liquid contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

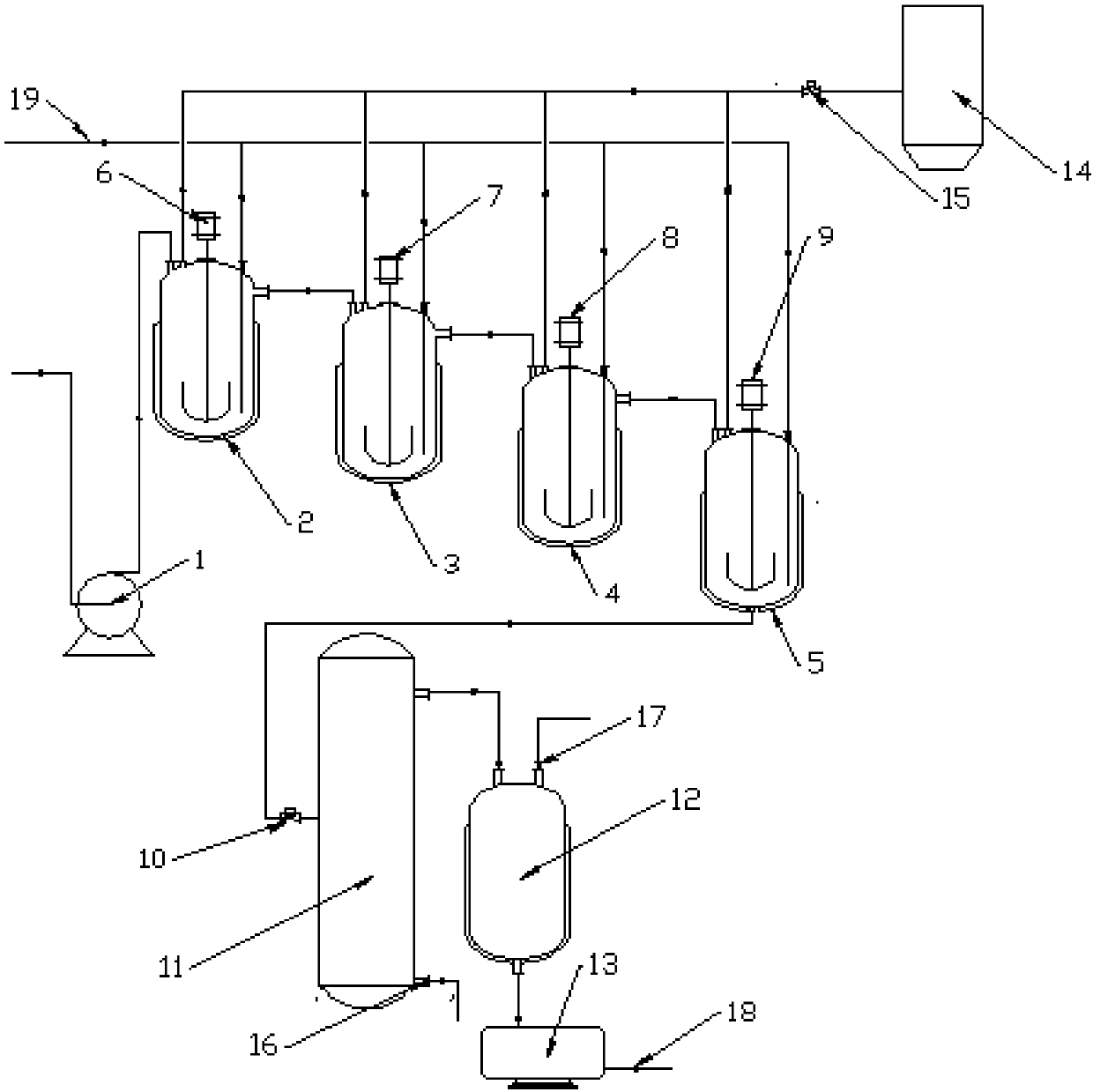

[0016] Such as figure 1 As shown, the reaction of methyl chloride and sodium 4-toluenesulfinate generates 1-methyl-4-methylsulfonylbenzene, and the steps of the synthesis method of 1-methyl-4-methylsulfonylbenzene of the present invention are:

[0017] a. Synthesis of 1-methyl-4-methylsulfonylbenzene: Sodium 4-toluenesulfinate enters into 1 through delivery pump 1 # In methylation kettle 2, methyl chloride gas enters into 1 by bubbling # Inside the methylation kettle 2, 1 # In the methylation kettle, the mixed reaction is carried out by self-priming stirring 6, and the reacted material is from 1 # The overflow port on the upper side of the methylation kettle 2 flows into and out of the 2 # In methylation kettle 3, methyl chloride gas enters into 2 by bubbling # In the methylation kettle 3, unreacted 4-sodium toluene sulfinate and methyl chloride are mixed and reacted by self-priming stirring 7, and the reacted material is from 2 # The overflow port on the upper side of th...

Embodiment 1

[0033] Put 4-sodium toluene sulfinate into 1 via delivery pump # In the methylation still, pass into methyl chloride gas, stir reaction, the mixed material after reaction is from 1 # Methylation kettle overflowed to 2 # Methylation still, pass into chloromethane gas to 2 # Methylation tank, stirring reaction, the mixed material after reaction from 2 # Methylation tank overflow into 3 # Methylation kettle, methyl chloride gas into 3 # Methylation tank, stirring reaction, after the reaction, the mixed material is from 3 # Methylation tank overflow into 4 # Methylation kettle, feed into the methyl chloride gas, stir the reaction, the reaction temperature of the four reactors is 92°C, the reaction pressure is 0.45MPa, the liquid level is ≤90%, from 4 # Samples were taken from the bottom of the methylation kettle, and the content of sodium 4-toluenesulfinate in the reaction liquid was analyzed by liquid chromatography. The content was 0.05%. After the reaction was completed, ...

Embodiment 2

[0037] Put 4-sodium toluene sulfinate into 1 via delivery pump # In the methylation still, pass into methyl chloride gas, stir reaction, the mixed material after reaction is from 1 # Methylation kettle overflowed to 2 # Methylation still, pass into chloromethane gas to 2 # Methylation tank, stirring reaction, the mixed material after reaction from 2 # Methylation tank overflow into 3 # Methylation kettle, methyl chloride gas into 3 # Methylation tank, stirring reaction, after the reaction, the mixed material is from 3 # Methylation tank overflow into 4 # Methylation tank, feed into methyl chloride gas, stir reaction, the reaction temperature of the four reactors is 90°C, the reaction pressure is 0.5MPa, the liquid level is ≤90%, from 4 # Samples were taken from the bottom of the methylation kettle, and the content of sodium 4-toluenesulfinate in the reaction liquid was analyzed by liquid chromatography. The content was 0.05%. After the reaction was completed, a 1-methyl-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com