Foam stabilizer and preparation method thereof

A foam stabilizer and bubble technology, applied in the field of chemical additives, can solve the problems of suspension, unfavorable foam stabilization, affecting product use, etc., and achieve the effects of good fluidity and stability, good dispersibility and low dosage.

Active Publication Date: 2018-03-23

山东丽波日化股份有限公司

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its disadvantages are: the production process requires high-speed homogeneous equipment for emulsification, and it needs to be equipped with a separate homogeneous equipment, and stearic acid is solid at 10-25 °C, and solid stearic acid is difficult to react with ammonia water, and incomplete reaction will lead to Small particles of stearic acid are suspended in the final product, which affects the use of the product. The final product must be filtered before it can be used

[0005] And when the products prepared by the technical solutions disclosed in the above two patents are used in water with high hardness, the ammonium stearate in the formula will generate water-insoluble fatty acid calcium soap and magnesium soap under the action of calcium and magnesium ions in the water , has a defoaming effect on the system, which is not conducive to foam stabilization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

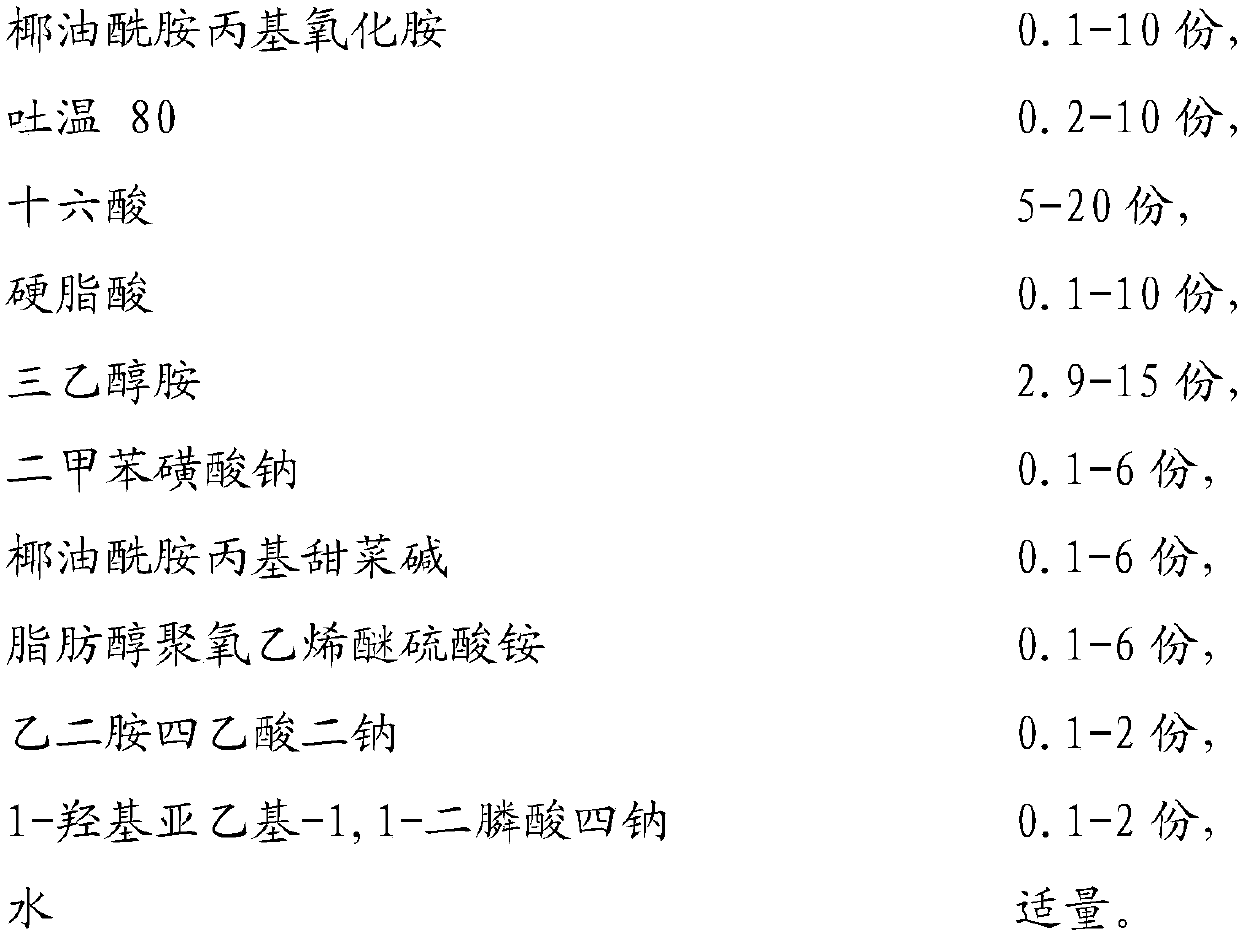

[0025] A kind of foam stabilizer, described foam stabilizer comprises the raw material of following weight portion:

[0026]

Embodiment 2

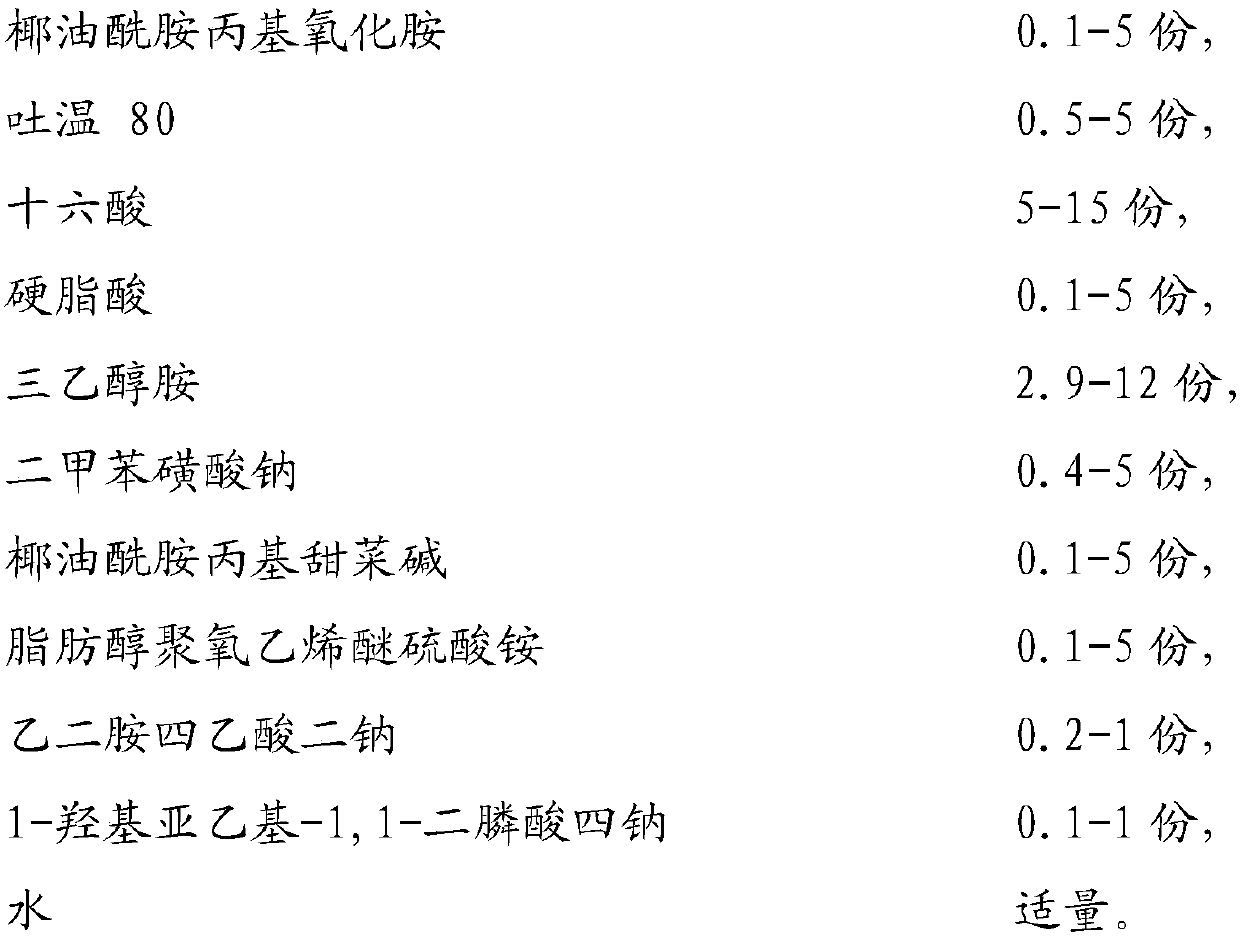

[0028] A kind of foam stabilizer, described foam stabilizer comprises the raw material of following weight portion:

[0029]

[0030]

Embodiment 3

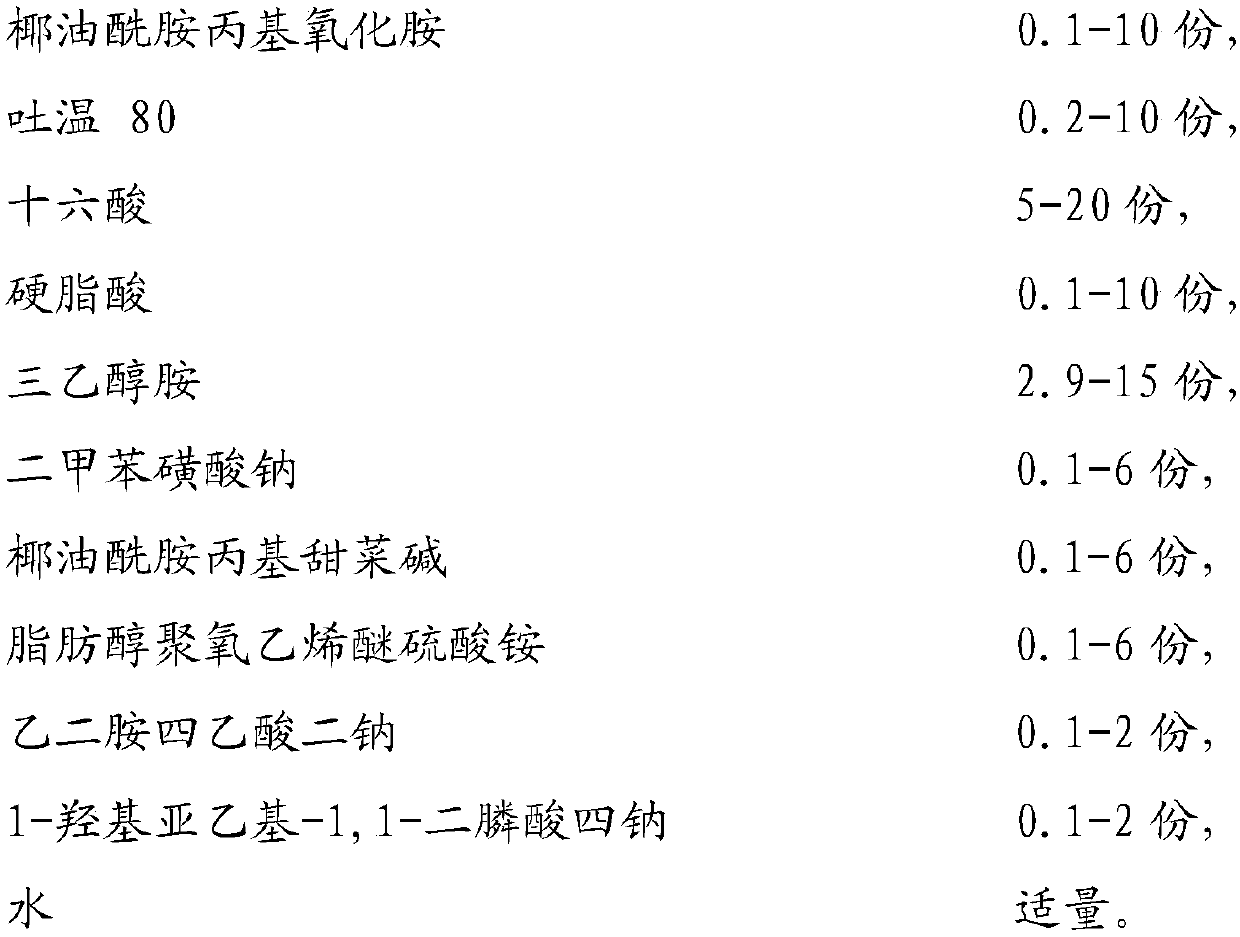

[0032] A kind of foam stabilizer, described foam stabilizer comprises the raw material of following weight portion:

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a foam stabilizer and a preparation method thereof. The foam stabilizer comprises 0.1-10 parts of cocamidopropyl dimethylamine oxide, 0.2-10 parts of tween 80, 5-20 parts of hexadecanoic acid, 0.1-10 parts of stearic acid, 2.9-15 parts of triethanolamine, 0.1-6 parts of sodium dimethyl benzene sulfonate, 0.1-6 parts of cocamidopropyl betaine, 0.1-6 pars of ammonium fatty alcohol polyoxyethylene ether sulfate, 0.1-2 parts of disodium ethylene diamine tetraacetate, 0.1-2 parts of 1-hydroxyethylidene-1,1-bis-phosphonic acid tetrasodium salt and water. The preparation method comprises the following steps: heating water, adding disodium ethylene diamine tetraacetate, 1-hydroxyethylidene-1,1-bis-phosphonic acid tetrasodium salt, ammonium fatty alcohol polyoxyethylene ether sulfate, cocamidopropyl betaine, cocamidopropyl dimethylamine oxide, sodium dimethyl benzene sulfonate and triethanolamine, stirring and dissolving to obtain a water phase; heating and melting tween80, hexadecanoic acid and stearic acid to obtain an oil phase; and rapidly mixing the water phase and the oil phase and stirring and cooling so as to obtain the foam stabilizer.

Description

technical field [0001] The invention relates to the technical field of chemical additives, in particular to a foam stabilizer. Background technique [0002] Due to the use of a large amount of harmful solvents in the production process of solvent-based polyurethane resin, it has been gradually replaced by water-based polyurethane coating with better environmental protection and safety in the production process of synthetic leather. In the production process of water-based polyurethane foam layer, it needs Foam stabilizers are added to increase the stability of the foam produced by the blowing agent. [0003] Application number is that the patent of CN200710067469.7 provides a kind of foam stabilizer and preparation method thereof, and this patent is made up of the component of following percentage by weight: ammonium stearate 20-35%; Sodium lauryl sulfate 1- 5%; coconut oil diethanolamide 1-10%; the balance is water. Its production process is as follows: add stearic acid, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08J9/00C08L75/04

CPCC08J9/00C08J9/0023C08J9/0028C08J9/0033C08J9/0038C08J2375/04

Inventor 丁建华夏庆勋

Owner 山东丽波日化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com