Light-transforming transparent plastic greenhouse film for cucumber planting, and preparation method thereof

A technology of transparent plastic and shed film, which is applied in the fields of botany equipment and methods, applications, climate change adaptation, etc. It can solve the problems of short service life of film, fast aging of film, and influence of plant growth, etc., so as to prolong service life and improve Utilization rate, the effect of promoting budding and flowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

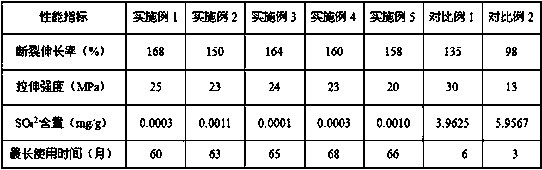

Examples

Embodiment 1

[0028] The steps of the light-transforming transparent plastic shed film for cucumber planting prepared by the present invention are as follows:

[0029] a. Take the benzoxazole compound, add N-methyl-2-pyrrolidone dihydrogen phosphate and hydrogen peroxide, mix according to the molar ratio of 0.5:3:6, and carry out the oxidative desulfurization reaction at 50°C. The reaction time is 8h, Oxygen-substituted sulfur-free benzoxazole compounds are obtained;

[0030] b. Add 3% rare earth metal ions of the mass of the benzoxazole compound to the oxygen-substituted sulfur-free benzoxazole compound obtained in step a for coordination to prepare a composite light conversion agent; wherein the rare earth metal ion is a rare earth element cerium;

[0031] c. Mix the composite light-changing agent obtained in step b with matrix resin, filler, surfactant, and light stabilizer according to the mass ratio of 5:50:20:2:0.5, put it into a closed plastic kneader, and Plastic scouring at 150°C...

Embodiment 2

[0035] The steps of the light-transforming transparent plastic shed film for cucumber planting prepared by the present invention are as follows:

[0036] a. Take the benzoxazole compound, add N-methyl-2-pyrrolidone dihydrogen phosphate and hydrogen peroxide, mix according to the molar ratio of 5:1.5:4, and carry out the oxidative desulfurization reaction at 60° C., and the reaction time is 5 hours. Oxygen-substituted sulfur-free benzoxazole compounds are obtained;

[0037] b. Add 5% rare earth metal ions of the mass of the benzoxazole compound to the oxygen-substituted sulfur-free benzoxazole compound obtained in step a for coordination to prepare a composite light conversion agent; wherein the rare earth metal ion is a rare earth element barium and strontium;

[0038] c. Mix the composite light-changing agent obtained in step b with matrix resin, filler, surfactant, and light stabilizer according to a mass ratio of 5:60:10:1:3, and put it into a closed plasticizing machine. ...

Embodiment 3

[0042] The steps of the light-transforming transparent plastic shed film for cucumber planting prepared by the present invention are as follows:

[0043] a. Take the benzoxazole compound, add N-methyl-2-pyrrolidone dihydrogen phosphate and hydrogen peroxide, mix according to the molar ratio of 3:5:10, and carry out the oxidative desulfurization reaction at 50°C, the reaction time is 4h, Oxygen-substituted sulfur-free benzoxazole compounds are obtained;

[0044] b. Add 8% rare earth metal ions of the mass of the benzoxazole compound to the oxygen-substituted sulfur-free benzoxazole compound obtained in step a for coordination to prepare a composite light conversion agent; wherein the rare earth metal ion is a rare earth element barium, strontium and cerium;

[0045] c. Mix the composite light-changing agent obtained in step b with matrix resin, filler, surfactant, and light stabilizer according to a mass ratio of 4:70:15:1.5:0.5, and put it into a closed plasticizing machine. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com