High-temperature-resisting and low-temperature-resisting extreme pressure lubricating grease with long service life and preparation method thereof

An extreme pressure grease and extreme pressure lubrication technology, applied in the field of grease, can solve problems such as poor product stability, affecting product low temperature performance, complex production process, etc., achieve good extreme pressure and wear resistance, and is beneficial to large-scale The effect of production and production process safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

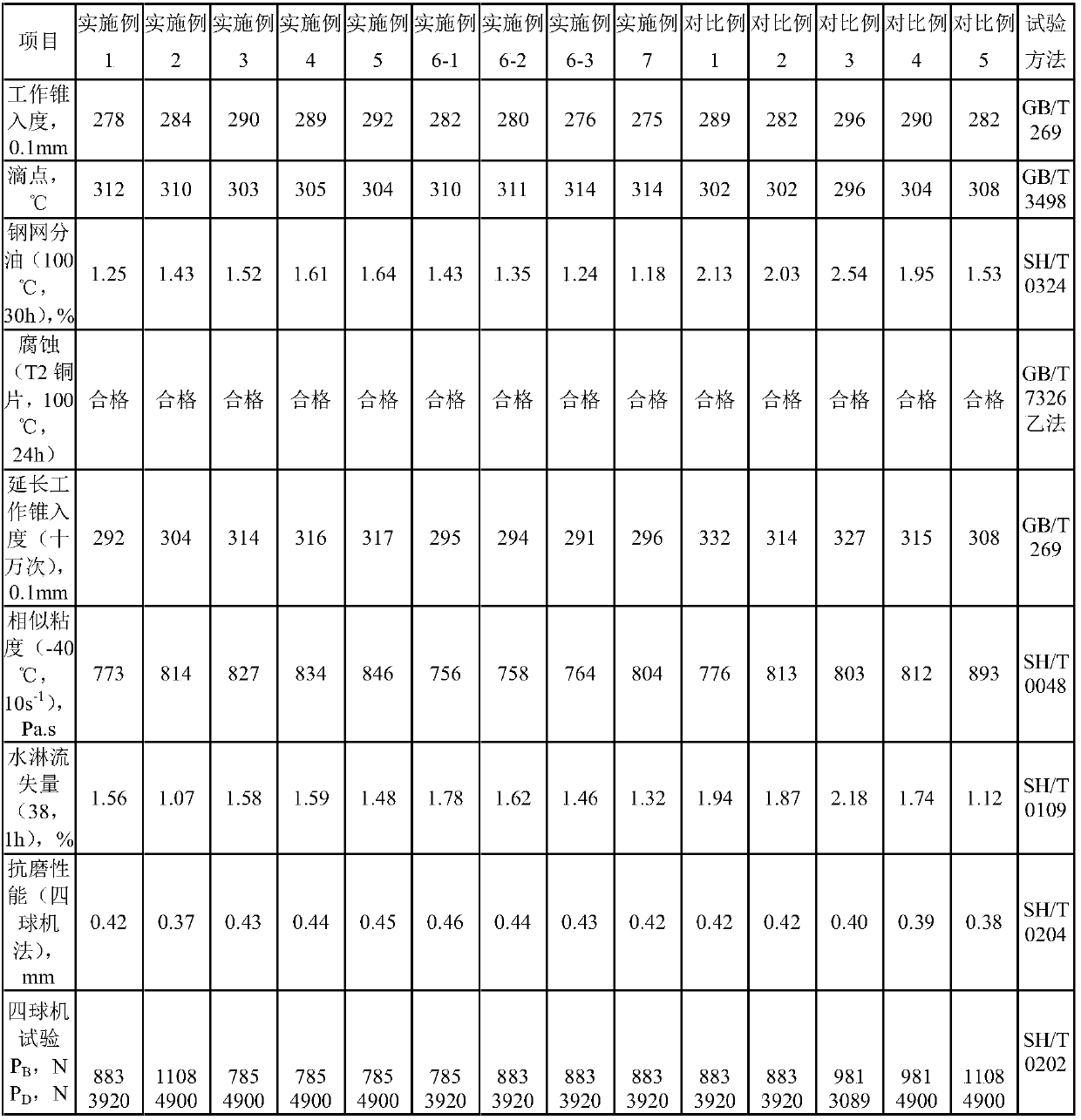

Embodiment 1

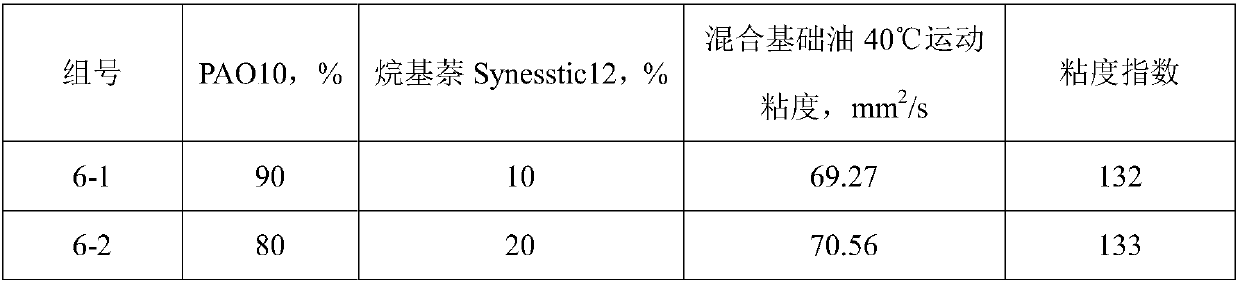

[0018] Get polyalphaolefin oil PAO10 92.88kg and alkylnaphthalene Synesstic12 30.96kg to mix as mixed base oil (40 ℃ kinematic viscosity of mixed base oil is 78mm 2 / s, the viscosity index is 123). Take 82.2kg of mixed base oil, 10.5kg of 12-hydroxystearic acid, and 3.54kg of sebacic acid and add them to the saponification reaction kettle in sequence, start stirring and raise the temperature to 82°C, then add 4.92kg of lithium hydroxide oil solution, after the addition is completed, put Saponification reaction at 95-105°C for 90 minutes, then heat up to 135°C for 30 minutes, add 0.45kg of antioxidant Irganox L57 and 0.75kg of structure improver Lubrizol2002D, continue to heat up to 215°C and keep it warm for 5 minutes, and finally transfer the material to the blending Add the remaining 41.64kg of mixed base oil to the kettle to lower the temperature. After the temperature drops below 90°C, add 1.5kg of molybdenum dialkyldithiocarbamate, 1.5kg of zinc dialkyldithiophosphate, an...

Embodiment 2

[0020] Get polyalphaolefin oil PAO40 37.8kg, PAO10 70.33kg and alkylnaphthalene Synesstic12 12.01kg to mix as mixed base oil (40 ℃ kinematic viscosity of mixed base oil is 115mm 2 / s, the viscosity index is 138). Take 80kg of mixed base oil, 13.5kg of 12-hydroxystearic acid, and 4.55kg of sebacic acid and add them to the saponification reactor in sequence, start stirring and raise the temperature to 82°C, then add in turn the emulsion containing 0.80kg of calcium hydroxide, 4.86kg of hydrogen Lithium oxide oil solution, saponification reaction at 105°C for 75 minutes after feeding, then heat up to 140°C for 40 minutes, add 0.075kg of antioxidant Irganox L57 and 0.75kg of structure improving agent Lubrizol 2002D, continue to heat up to 220°C and keep warm for 5 Minutes, finally transfer the material to the blending kettle, add the remaining 40.14kg of mixed base oil to cool down, and add 3kg of molybdenum dialkyldithiophosphate and 1.5kg of zinc dialkyldithiophosphate in sequen...

Embodiment 3

[0022] Get polyalphaolefin oil PAO10 103.29kg and alkyl naphthalene SynNaph23 19.4kg to mix as mixed base oil (40 ℃ kinematic viscosity of mixed base oil is 80mm 2 / s, the viscosity index is 129). Take 86kg of mixed base oil, 10.5kg of 12-hydroxystearic acid, and 4.23kg of sebacic acid and add them to the saponification reaction kettle in sequence, and start stirring to raise the temperature to 82°C, then add 5.08kg of lithium hydroxide oil solution, and after the addition is completed, the temperature rises at 95°C. ~105°C saponification reaction for 90 minutes, then heat up to 135°C for 30 minutes, add 0.25kg of antioxidant Irganox L135, 0.5kg of Irganox L57 and 1.5kg of structure improver Lubrizol 2002D, continue to heat up to 210°C and hold for 5 minutes, and finally Transfer the material to the blending kettle, add the remaining 36.69kg of mixed base oil to cool down, and then add 2.25kg of molybdenum dialkyldithiocarbamate, 1.5kg of thiadiazole derivatives, and dinonylnap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com