A preparation method of electrospun nanofiber composite modified screen printing electrode

A technology of electrospinning nanofibers and screen printing electrodes, which is applied in the direction of nanotechnology, nanotechnology, cable/conductor manufacturing, etc., can solve the problems of high experimental requirements, insignificant specific surface area enlargement, poor stability, etc., and achieve simple process, Large effective specific surface area, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

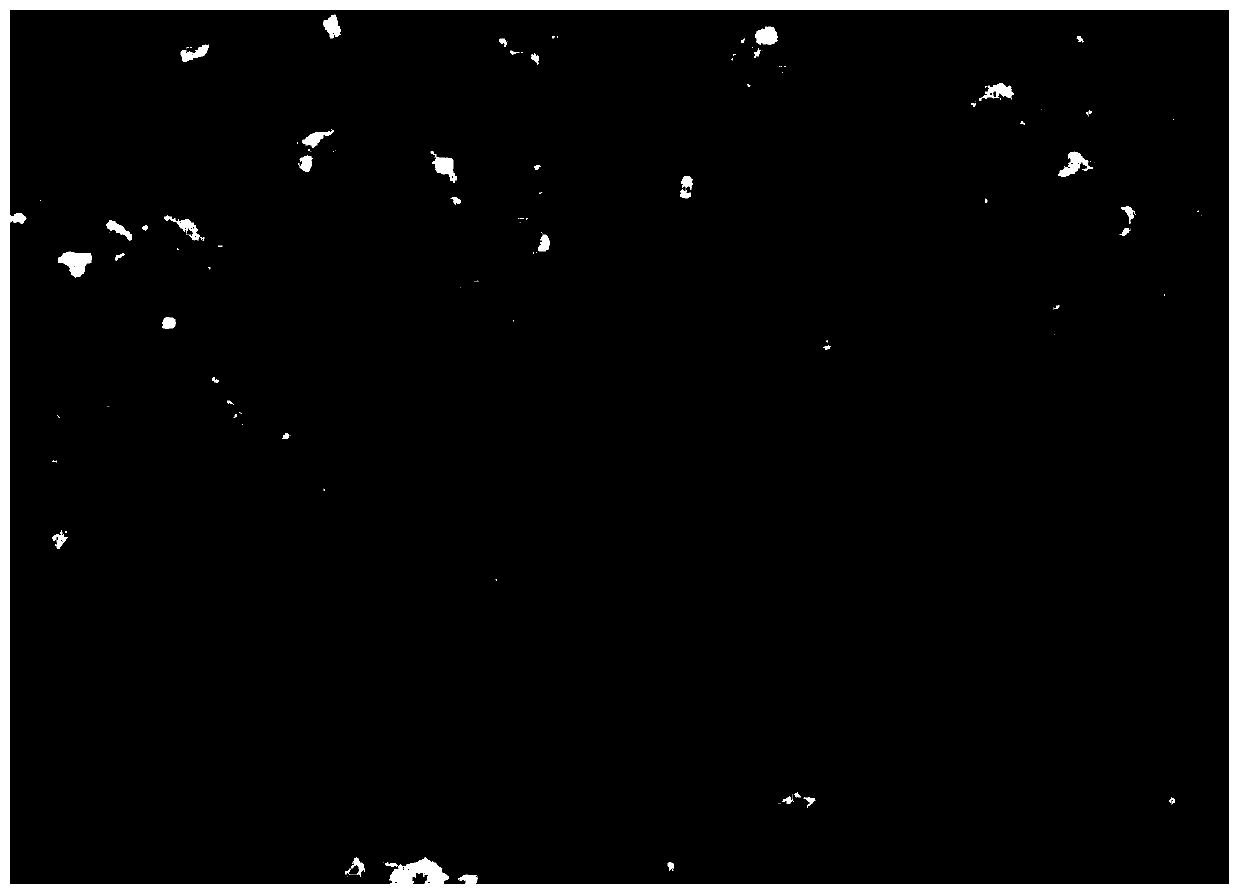

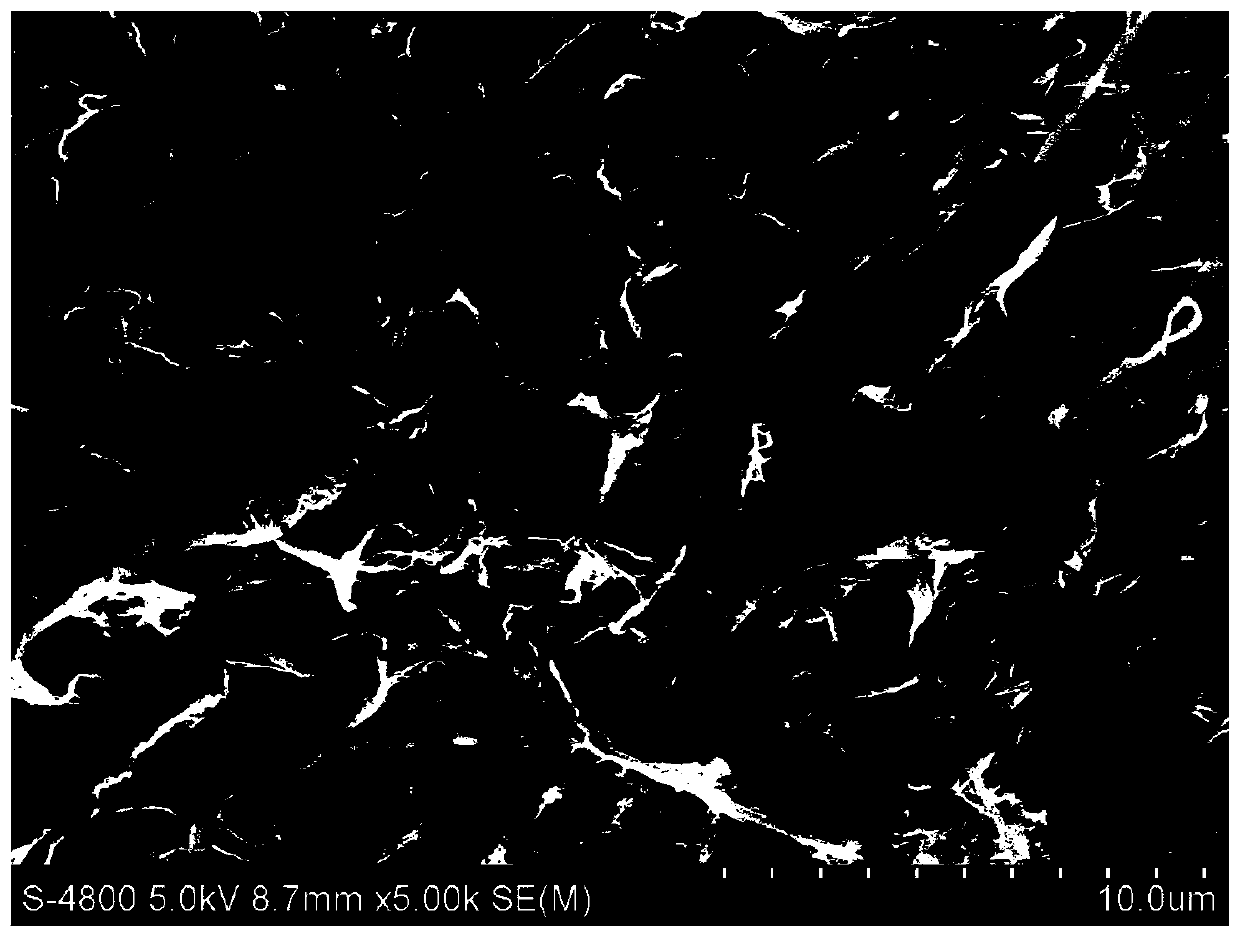

[0043] (1) Preparation of electrospun nanofiber membrane by electrospinning method:

[0044] Dissolve PA6 and GR in a mixed solvent of formic acid / m-cresol / DMF (20:1:1~1:1:1, v / v) to form a polyamide 6-graphene mixture, and stir continuously at room temperature until obtaining Uniform and transparent spinnable solution. The spinning solution is placed in a medical syringe, and a micro-injection pump is used to supply the liquid. The positive and negative electrodes of the high-voltage electrostatic generator are respectively connected to the injection needle and the conductive receiving plate, and the high-voltage static electricity is directly applied to the needle. Obtain PA6-GR film;

[0045] Parameter setting: Needle: No. 5~10, Voltage: 10~30V, Syringe flow rate: 0.1~1.0mL / h, spacing (needle and electrode): 5~10cm, spinning time: 2~5min, ambient temperature: 20 ~30°C, Humidity: <40%.

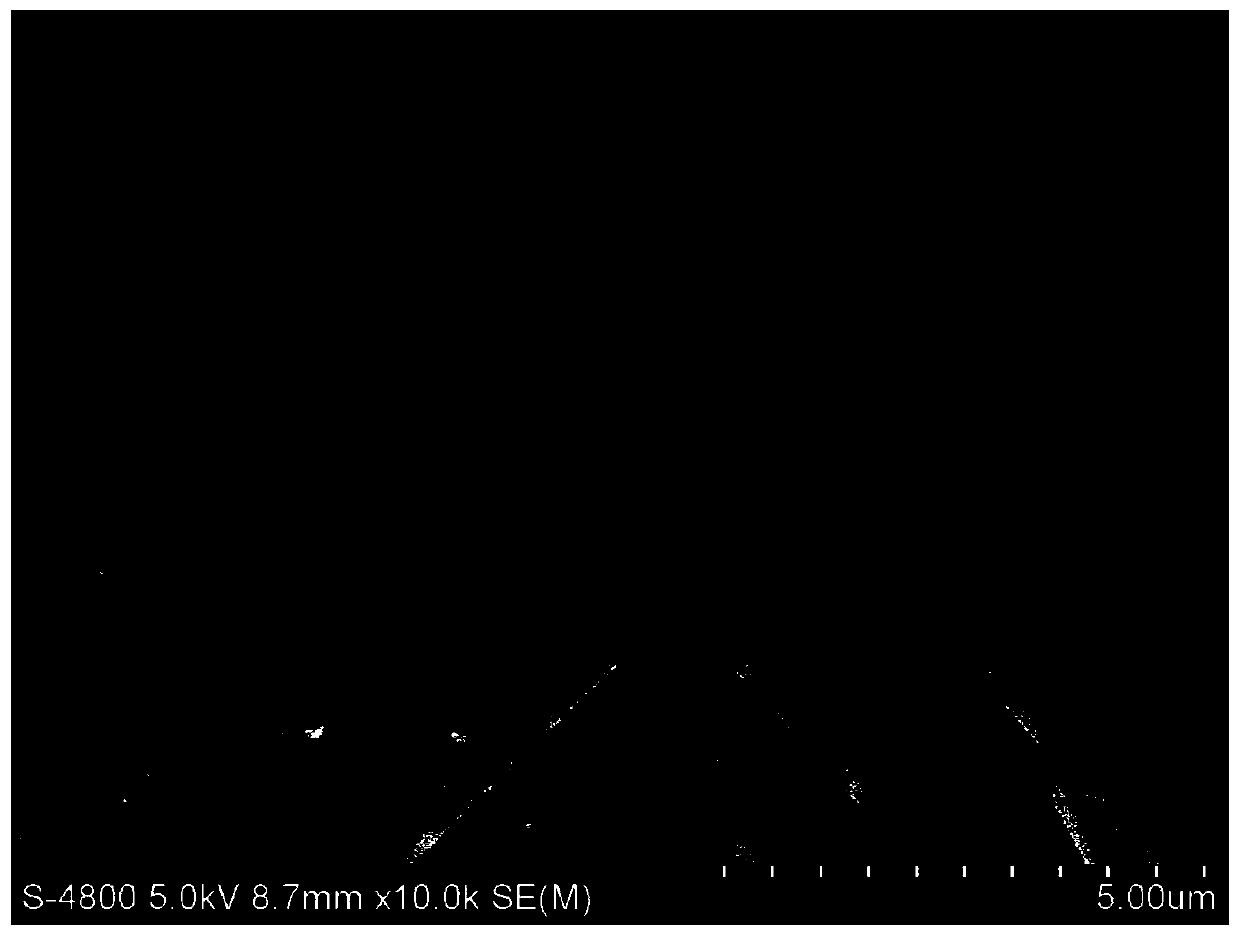

[0046] (2) Preparation of electrospun nanofiber composites:

[0047] Remove the PA6-GR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com