Equipment cooling fan intelligent management device and method

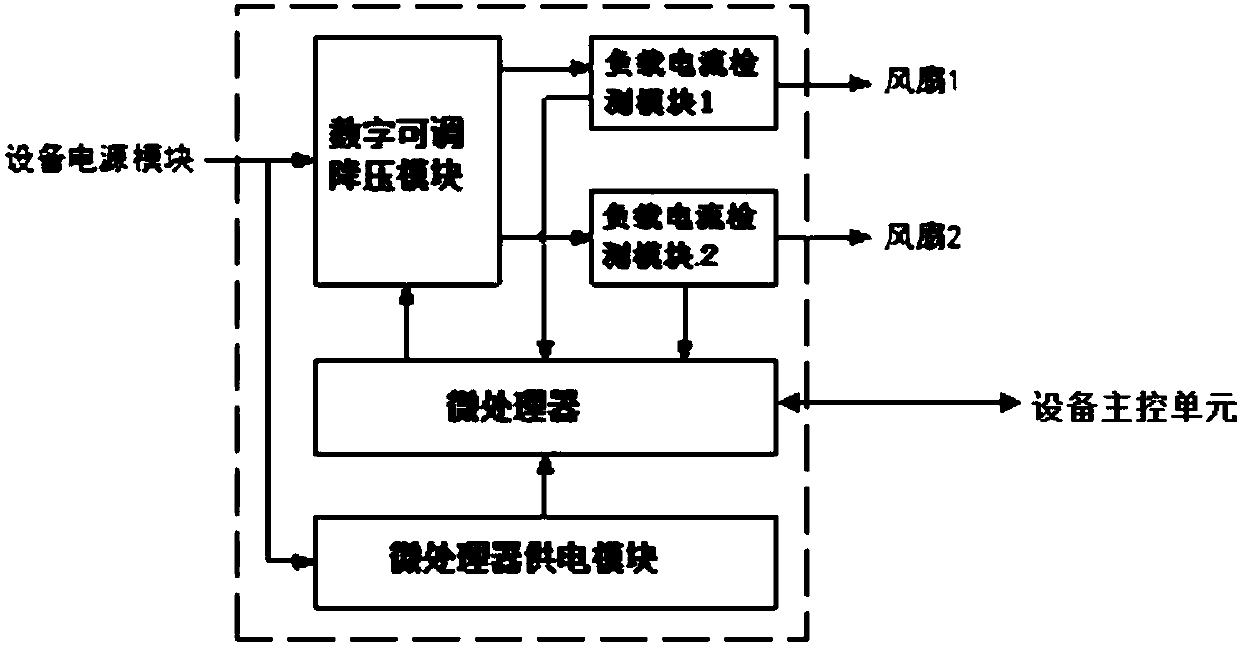

A technology of intelligent management device and heat dissipation fan, which is applied in the direction of mechanical equipment, emergency protection circuit device, components of pumping device for elastic fluid, etc., can solve the problem of high air disturbance noise and electromagnetic signal interference, and unsuitable heat generation The whole machine equipment, low heat dissipation efficiency and other problems, achieve low noise index, improve long-term working reliability, and improve the effect of perception ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

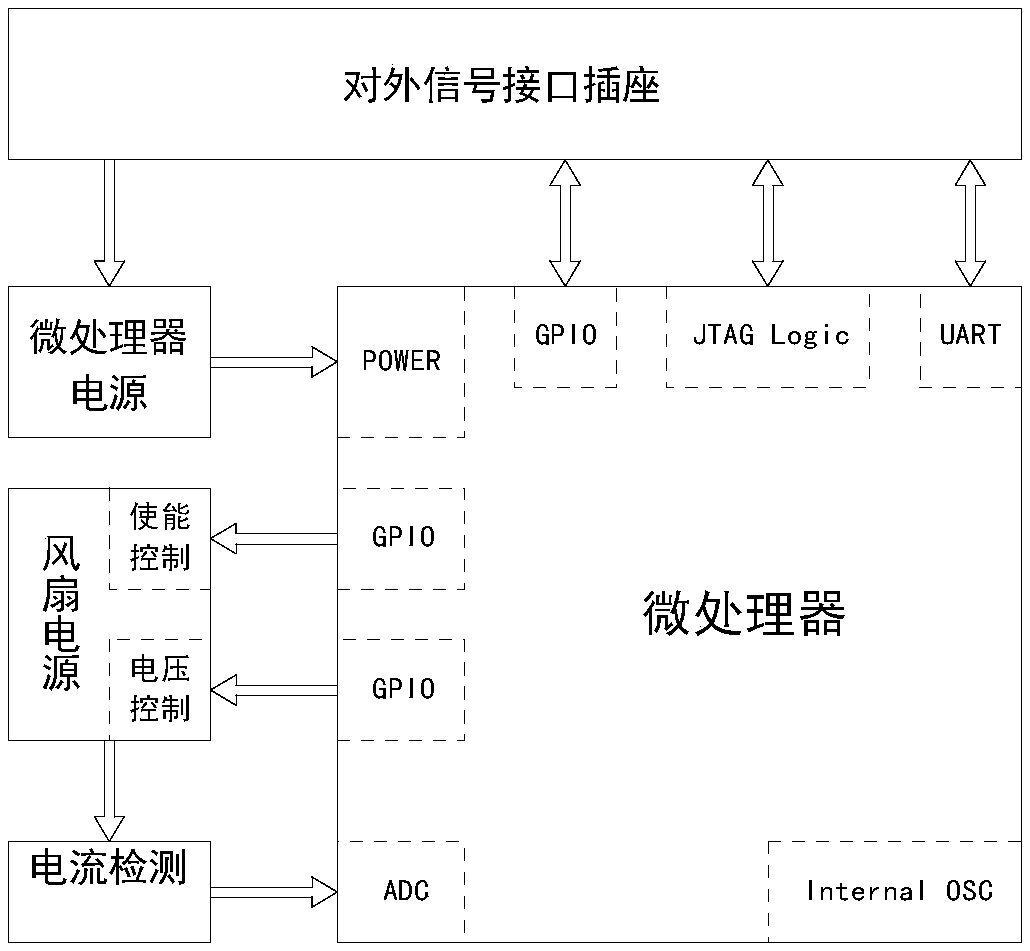

Method used

Image

Examples

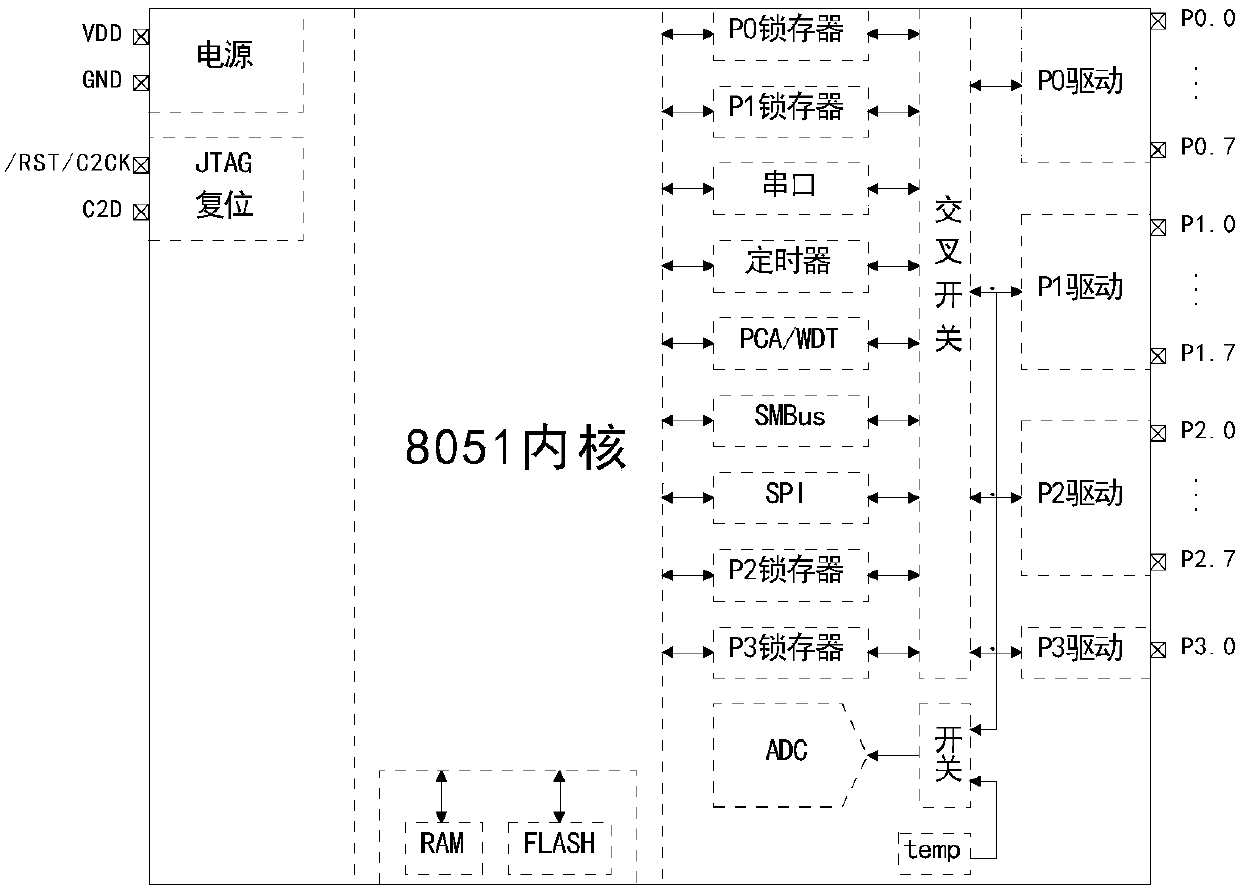

Embodiment 1

[0039] The fan power step-down and detection circuit in Example 1 is mainly composed of an input power filter capacitor, a power step-down chip and peripheral circuits, an output power filter capacitor, a power indicator light-emitting diode, two load current detection chips and peripheral circuits. like Figure 4 As shown, 1 is the system input power signal, and its voltage is not less than 15V; 2 is the input power signal filter capacitor group, which can suppress the interference signal between the fan power supply and the system power supply; 3 is the power step-down chip, which can be controlled by software Control it to enter the sleep state, and also set its output voltage value; 4 is the step-down output power signal filter capacitor group, which can effectively reduce the ripple of the output power and improve the quality of the power signal; 5 is to enable the control of the IO port, output power Step-down chip work enable control signal, through which the fan can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com