A method for rapidly aging tobacco leaves using natural yeast

A technology of natural yeast and tobacco leaves, applied in the field of tobacco, has achieved good application prospects, easy and controllable preparation, and the effect of saving aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

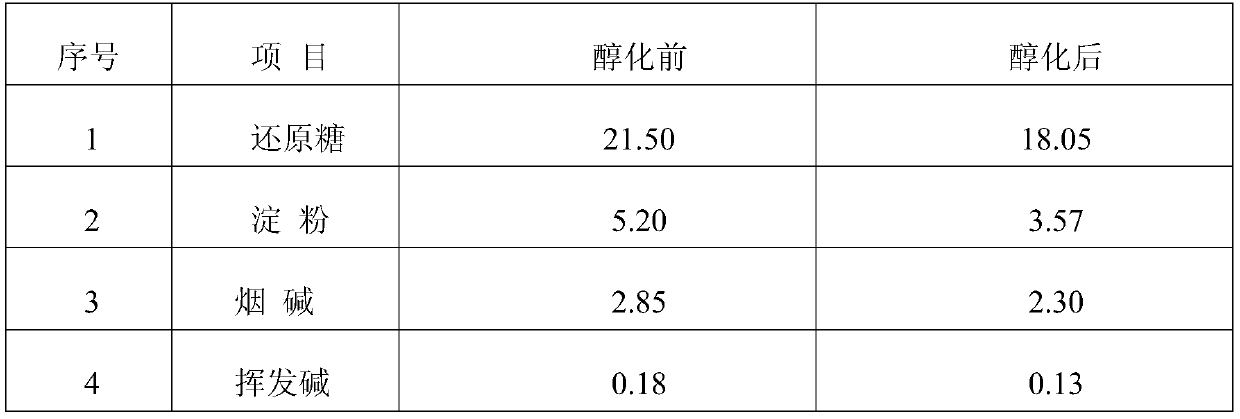

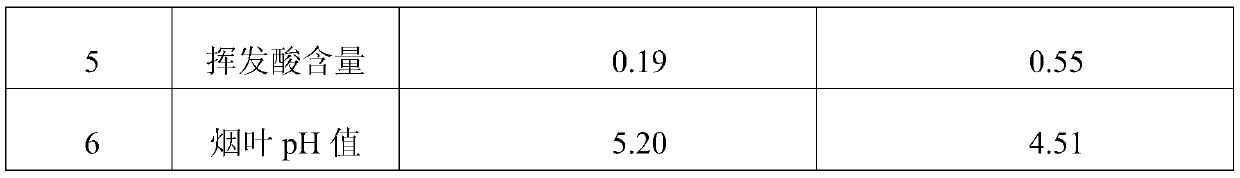

Embodiment 1

[0026] Embodiment 1, a kind of method utilizing natural yeast to quickly age tobacco leaves is characterized in that the method comprises the following steps:

[0027] (1) Remove stalks, green miscellaneous fruits, moldy and rotten fruits and other sundries from 10 kg of selected mature "black grape" grapes (produced in Yunnan) whose skin color is black and purple, covered with white frost, and taste sweet but not sour, and then Crush the intact grape grains and put them into a 10-liter clean glass jar, the amount of which should not exceed two-thirds of the capacity of the container, and cover the lid (not sealed); place the glass jar on 24-28 ℃ room environment, natural fermentation for 48 hours, stirring once every 4-8 hours, stirring the floating grape skins into the juice;

[0028] (2) 48 hours after the grapes are put into the tank, when the temperature of the tank wall rises slightly and the air bubbles in the tank increase, the surrounding grape skins will roll and flo...

Embodiment 2

[0039] Embodiment 2, a kind of method utilizing natural yeast to quickly age tobacco leaves is characterized in that the method comprises the following steps:

[0040] (1) Remove stalks, green miscellaneous fruits, moldy and rotten fruits and other sundries from 10 kg of selected mature "black grape" grapes (produced in Yunnan) whose skin color is black and purple, covered with white frost, and taste sweet but not sour, and then Crush the intact grape grains and put them into a 10-liter clean glass jar, the amount of which should not exceed two-thirds of the capacity of the container, and cover with a lid (not sealed); place the glass jar on 24-28 ℃ room environment, natural fermentation for 48 hours, stirring once every 4-8 hours, stirring the floating grape skins into the juice;

[0041] (2) 48 hours after the grapes are put into the tank, when the temperature of the tank wall rises slightly and the air bubbles in the tank increase, the floating of the bubbles will drive the...

Embodiment 3

[0052] Embodiment 3, a kind of method utilizing natural yeast to quickly age tobacco leaves is characterized in that the method comprises the following steps:

[0053] (1) Remove 100 kg of mature "black grape" grapes (produced in Yunnan) from stems, green miscellaneous fruits, moldy and rotten fruits and other sundries, break the intact grape grains, put them into a 100-liter fermenter, and put them into The amount should not exceed two-thirds of the container capacity, cover the lid (not sealed), and control the environment of the tank at 26-28°C, ferment naturally for 48 hours, stir once every 4-8 hours, and The floating grape skins are stirred into the juice;

[0054] (2) After the grapes were put into the tank for 48 hours, the fermented product obtained in step (1) was filtered to remove large particles of impurities with a plate and frame filter, and the filtrate after the coarse filtration was collected, which was the natural yeast used;

[0055] (3) Place the natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com