Mold-proof refreshing corrugated paperboard and preparation method thereof

A technology for corrugated cardboard and corrugated core paper, which is applied in the field of mildew-proof and fresh-keeping corrugated cardboard and its preparation, can solve the problems of short preservation time and poor preservation effect of fruits and vegetables, shorten the preservation time, improve the reaction efficiency and the utilization rate of raw materials, and prolong the The effect of preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

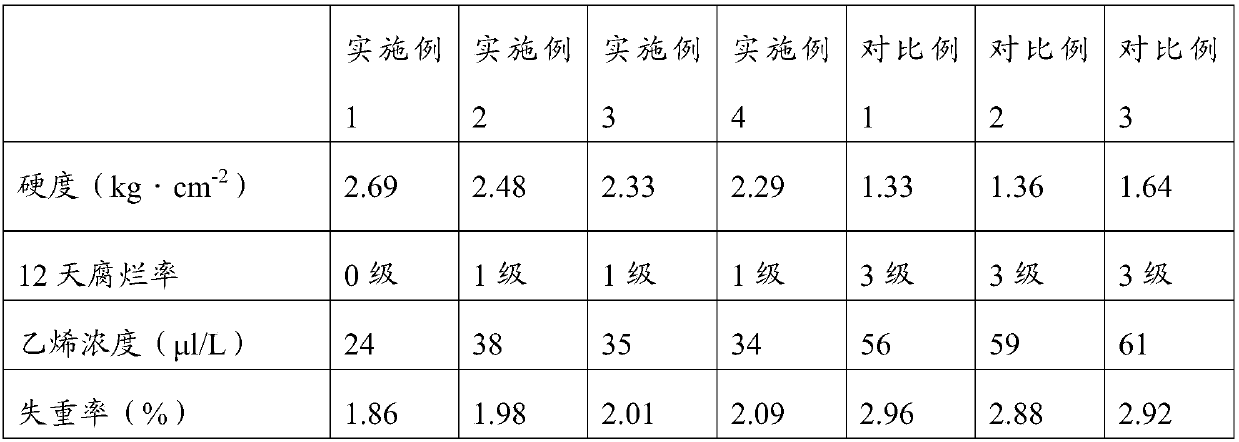

Examples

preparation example Construction

[0031] The method for preparing the above mildew-resistant and fresh-keeping corrugated cardboard according to an embodiment of the present invention includes the following steps S1-S3:

[0032] S1. Form an anti-mildew coating on one side of the corrugated medium paper.

[0033] Specifically, the raw materials of each component are weighed according to the above ratio, mixed with water and pulped to obtain an anti-mold coating, and then coated on one side of the corrugated medium paper to form an anti-mold coating after drying.

[0034] S2. Coating the ethanol solution of hollow porous polymer microspheres on the side of the corrugated core paper away from the anti-mold coating, coating the slurry obtained by mixing the adsorbent with water on the side of the corrugated core paper away from the anti-mold coating, and drying Finally, a fresh-keeping coating is formed.

[0035] Thus, the fresh-keeping coating is composed of hollow porous polymer microspheres loaded with adsorbe...

Embodiment 1

[0044] One side of the corrugated core paper is coated with an anti-mold coating to form an anti-mold coating. The anti-mold coating includes 78% water-absorbing resin and 22% anti-mold agent, wherein the water-absorbing resin is composed of 7% polyvinyl alcohol 1788, 6% polyvinyl alcohol Vinyl alcohol 2488 and 87% methyl methacrylate - butyl acrylate - acrylic acid copolymer, antifungal agent is composed of 25% sodium ascorbate, 25% salicylamine and 50% carson.

[0045] Coating the ethanol solution of hollow porous polymer microspheres on the side of the corrugated core paper away from the anti-mildew coating, the hollow porous polymer microspheres are made of acrylic ester copolymer. The adsorbent was obtained by weighing each component according to the following mass percentages: 62% potassium permanganate, 27% methylcyclopropene, 8% chromium trioxide, 2% activated carbon and 1% montmorillonite. Mix the adsorbent with water to obtain a slurry, the mass percent concentration...

Embodiment 2

[0047] One side of the corrugated core paper is coated with an anti-mold coating to form an anti-mold coating. The anti-mold coating includes 78% water-absorbing resin and 22% anti-mold agent, wherein the water-absorbing resin is composed of 7% polyvinyl alcohol 1788, 6% polyvinyl alcohol Vinyl alcohol 2488 and 87% methyl methacrylate - butyl acrylate - acrylic acid copolymer, antifungal agent is composed of 25% sodium ascorbate, 25% salicylamine and 50% carson.

[0048] Coating the ethanol solution of hollow porous polymer microspheres on the side of the corrugated core paper away from the anti-mildew coating, the hollow porous polymer microspheres are made of acrylic ester copolymer. Mix potassium permanganate with water to obtain slurry, the mass percentage concentration of potassium permanganate is 0.5%, apply the slurry on the side of the corrugated core paper away from the anti-mildew coating, and then put it in an environment of 20°C for slow drying After 5 hours, put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com