Integral vehicle thermal management system for plug-in hybrid electric vehicle

A hybrid electric vehicle and management system technology, applied in the field of thermal management of hybrid electric vehicles, can solve problems such as no improvement in economy and emission performance, heat generation to provide warm air, increase fuel consumption, etc., to improve vehicle economy and emission performance , improve life and efficiency, and ensure the effect of function and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

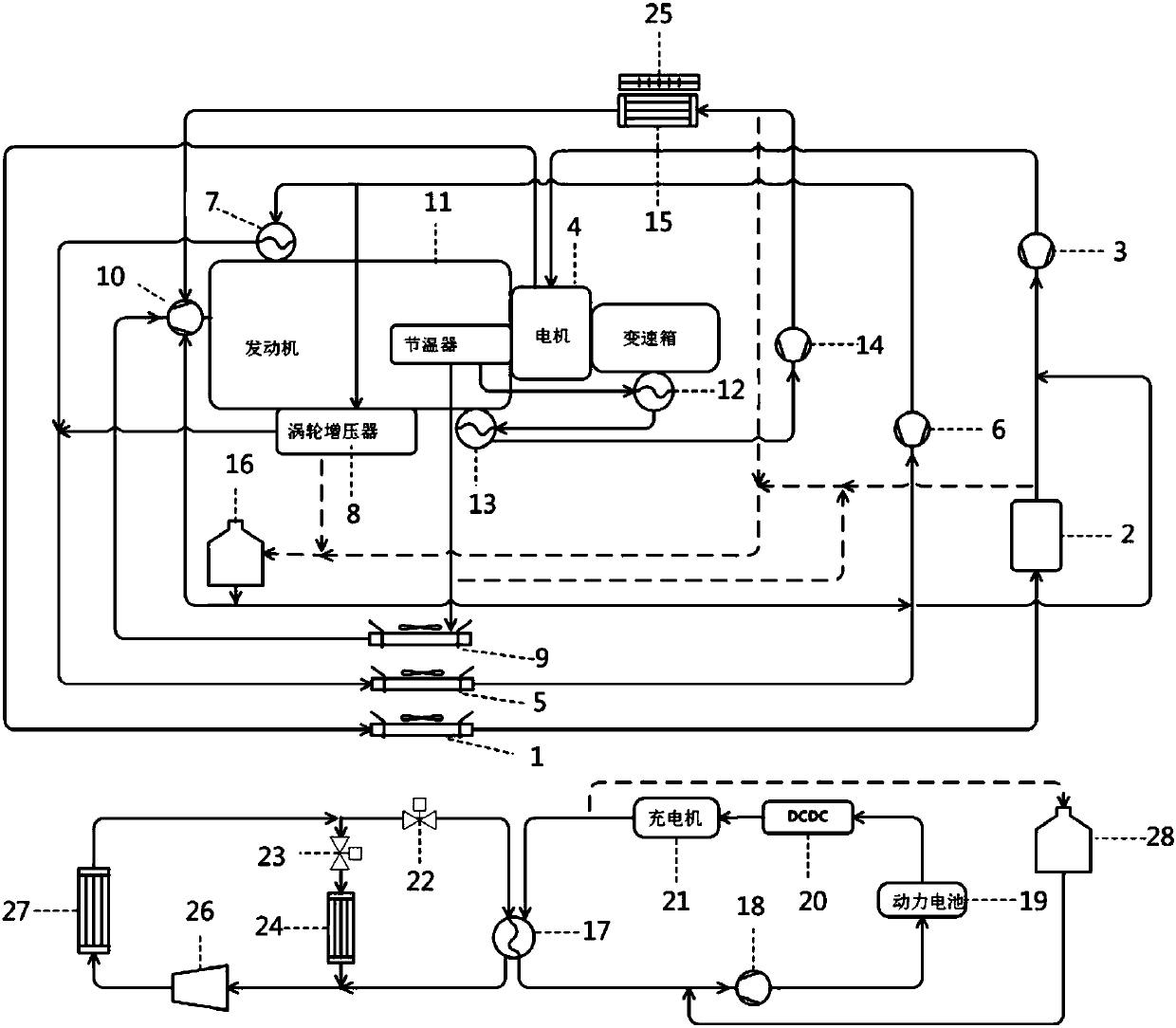

[0040] This embodiment provides a vehicle thermal management system for a plug-in hybrid electric vehicle, including a high-temperature cooling system, a medium-temperature cooling system, a low-temperature cooling system, a battery cooling system, and an air-conditioning system.

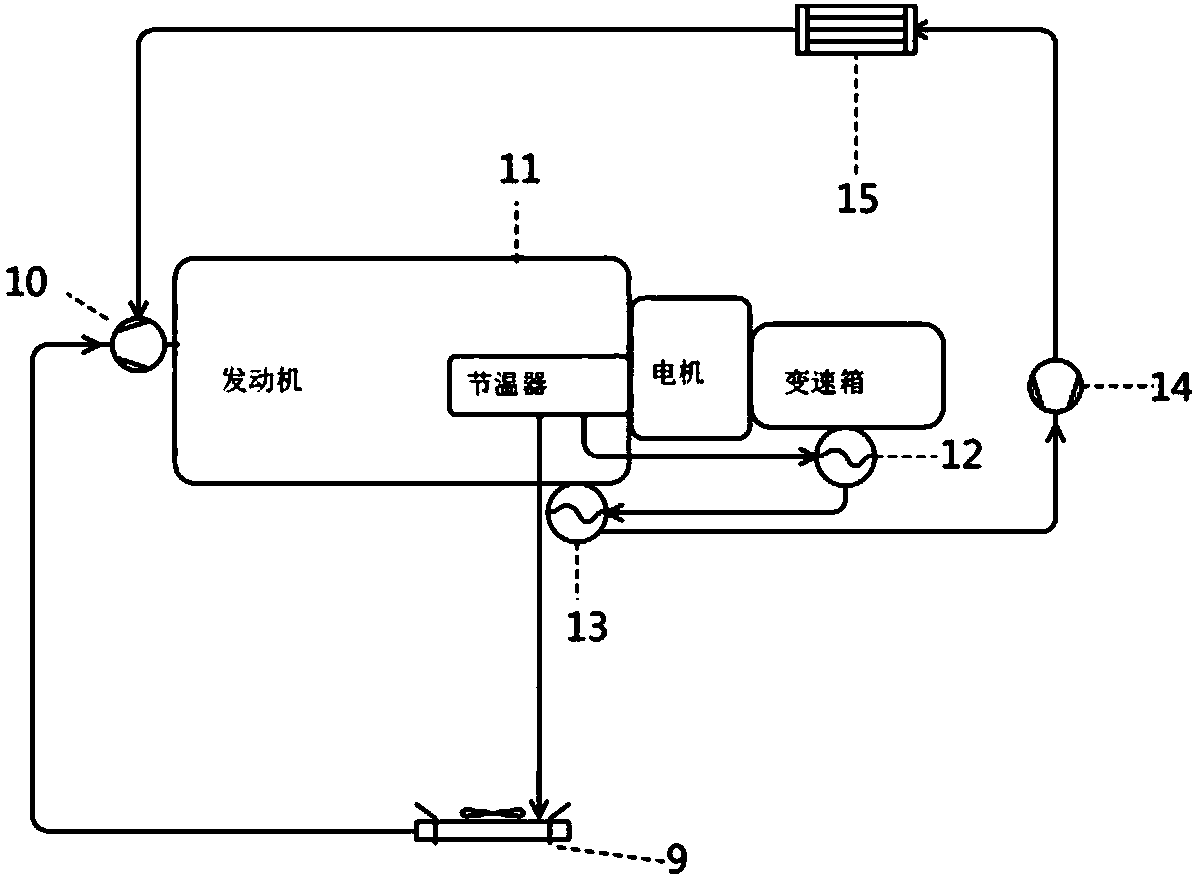

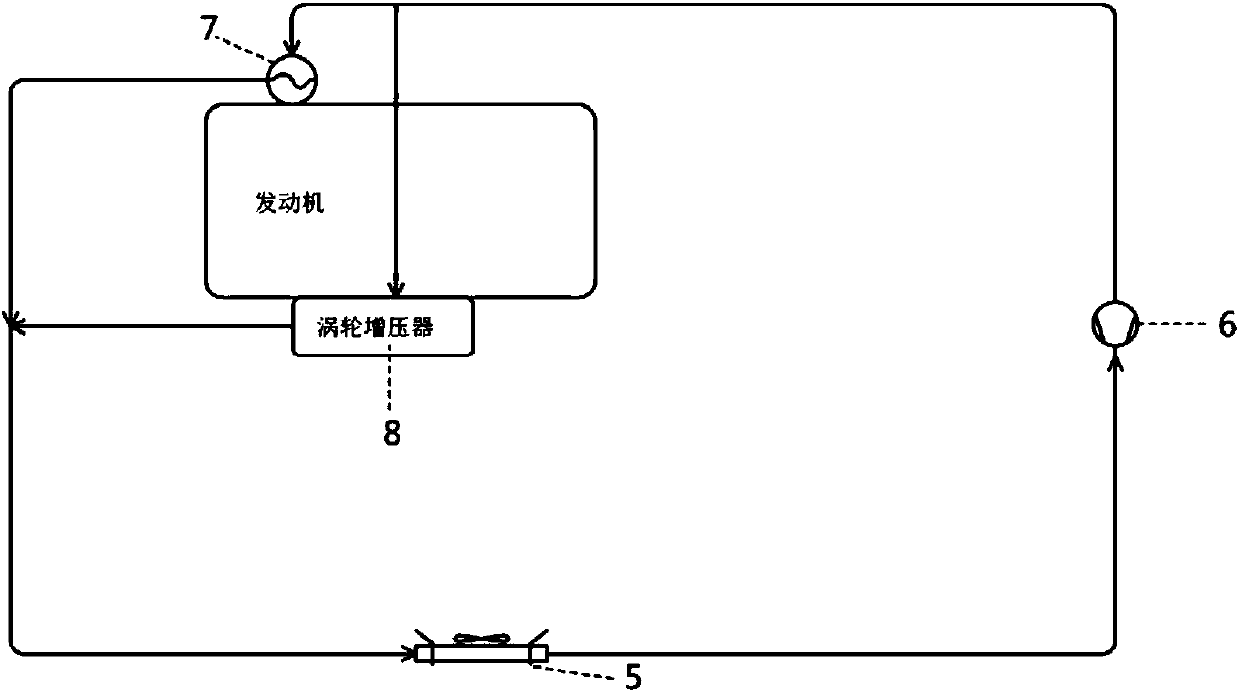

[0041] The high-temperature cooling system includes a high-temperature radiator 9, a mechanical water pump 10, an engine 11, a transmission heat exchanger 12, an oil cooler 13, a high-temperature water pump 14, an indoor warm air radiator 15 and an expansion tank 16;

[0042] refer to figure 2 , in this embodiment, the high-temperature cooling system includes a large circulation cooling circuit and a small circulation cooling circuit; the large circulation cooling circuit circulates through the mechanical water pump 10, the engine 11 and the high temperature radiator 9 in sequence according to the flow direction of the circulating water; the small circulation cooling circuit follows the The circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com