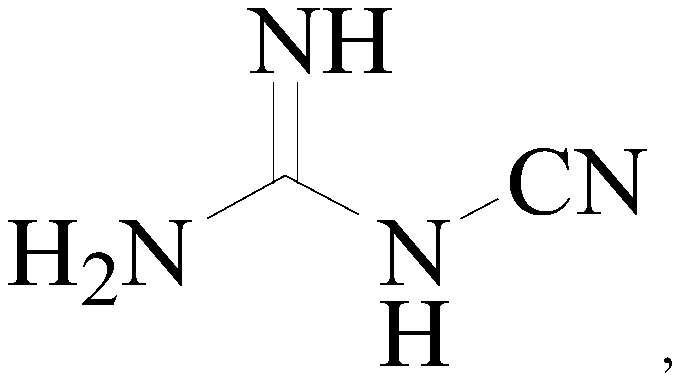

Preparation method of dicyandiamide

A technology of dicyandiamide and triethylamine, which is applied in the field of preparation of dicyandiamide, can solve the problems of serious environmental pollution and high energy consumption in the production of lime nitrogen raw materials, achieve high yield, overcome high energy consumption and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

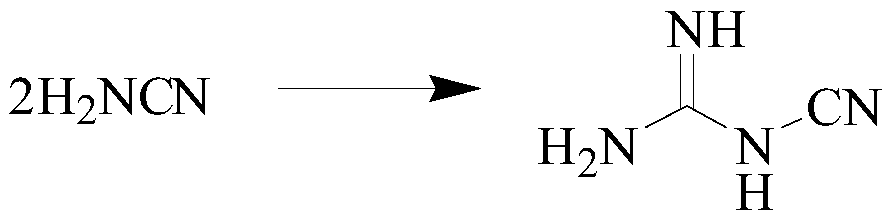

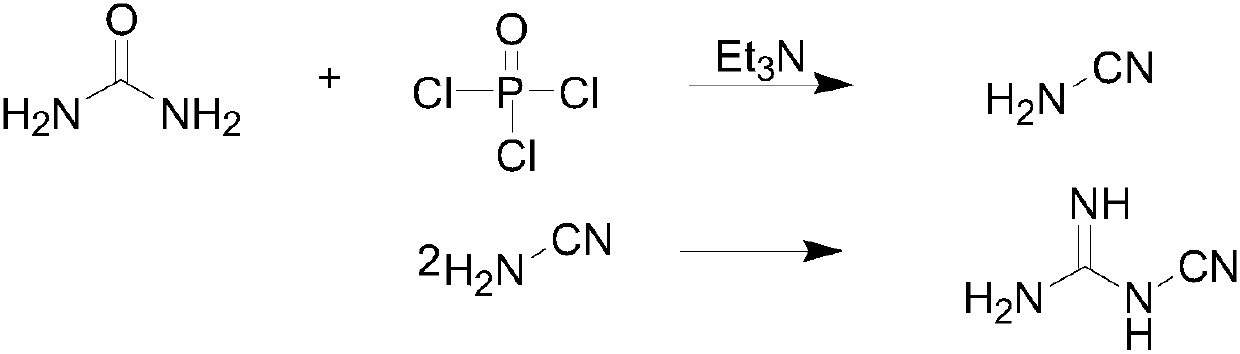

Method used

Image

Examples

Embodiment 1

[0025] Add 0.05mol urea, 30mL tetrahydrofuran, and 0.045mol triethylamine into the four-necked flask, and then add 0.015mol phosphorus oxychloride in batches at intervals of 20 minutes, and add 0.015mol phosphorus oxychloride in batches at 45°C for 5 hours. Yellow transparent liquid. After the reaction was over, the solvent was distilled off under reduced pressure, and the solvent was distilled off with saturated NaCO 3 Wash the distillation product, add ethanol to remove the salt in the system, and filter. The product was extracted with ethyl acetate, and the conversion rate of urea was 100% and the yield was 92.9% through liquid-mass analysis and liquid phase quantitative analysis.

Embodiment 2

[0027] Add 0.5mol urea, 150mL tetrahydrofuran, and 0.45mol triethylamine into the four-neck flask, and then add 0.15mol phosphorus oxychloride in batches at intervals of 20 minutes, and add 0.15mol phosphorus oxychloride in batches at 55°C for 6 hours. Yellow transparent liquid. After the reaction was over, the solvent was distilled off under reduced pressure, and the solvent was distilled off with saturated NaHCO 3 Wash the distillation product, add ethanol to remove the salt in the system, and filter. The product was extracted with ethyl acetate, and the conversion rate of urea was 100% and the yield was 87.3% through liquid-mass analysis and liquid phase quantitative analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com