Intumescent flame retardant and preparation method thereof

A technology of intumescent flame retardant and flame retardant synergist, which is applied in the field of intumescent flame retardant materials, can solve the problems of insufficient thermal stability and poor char formation, and achieve the goal of reducing heat release rate, burning speed and mobility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

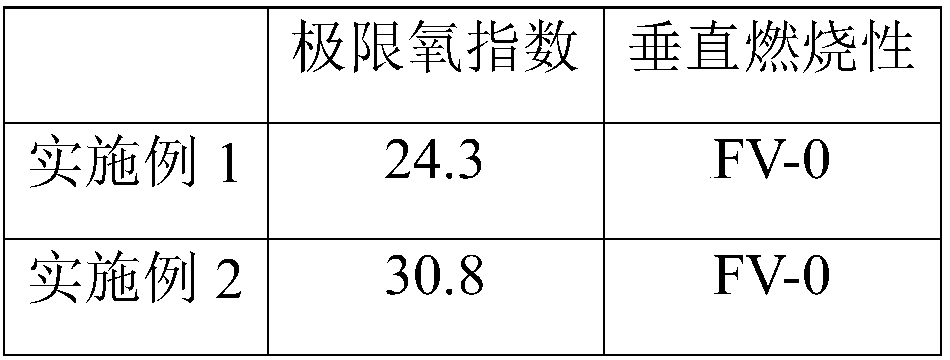

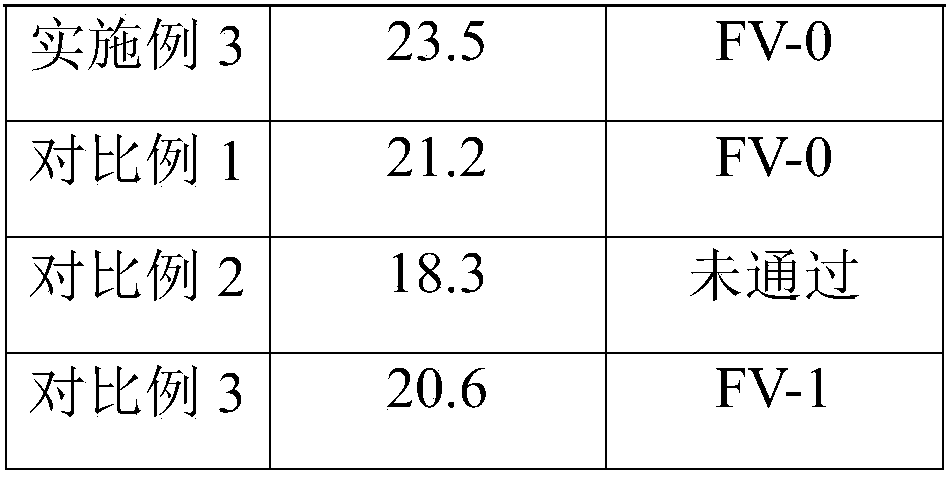

Examples

Embodiment 1

[0023] An intumescent flame retardant comprising the following components in parts by weight:

[0024] 10 parts of sodium stearate, 20 parts of glucomannan, 80 parts of triaryl phosphate, 20 parts of phenolic resin, 20 parts of aminomethylphosphonic acid, 10 parts of tetravinyltetramethylcyclotetrasiloxane, silicon oxide 10 parts, baicalin 5 parts, cinnamate 2 parts, coumarin ester 2 parts and triphenyl phosphite 5 parts.

[0025] The preparation method of above-mentioned intumescent flame retardant comprises the following steps:

[0026] Mix triaryl phosphate ester and phenolic resin according to the formula, stir evenly, then add aminomethylphosphonic acid, tetravinyltetramethylcyclotetrasiloxane, silicon oxide and triphenyl phosphite, continue stirring, reaction 1~ 2h, and then add sodium stearate, glucomannan, baicalin, cinnamate and coumarin ester to prepare an intumescent flame retardant.

Embodiment 2

[0028] An intumescent flame retardant comprising the following components in parts by weight:

[0029] 18 parts of lauric acid soap, 26 parts of glucomannan, 78 parts of triaryl phosphate, 20 parts of phenolic resin, 20 parts of aminomethylphosphonic acid, 8 parts of tetravinyltetramethylcyclotetrasiloxane, zinc borate 12 parts, 5 parts of baicalin, 3 parts of cinnamate, 3 parts of coumarin ester and 8 parts of diphenylisooctyl phosphite.

[0030] The preparation method of above-mentioned intumescent flame retardant comprises the following steps:

[0031] Mix triaryl phosphate and phenolic resin according to the formula, stir evenly, then add aminomethylphosphonic acid, tetravinyltetramethylcyclotetrasiloxane, zinc borate and diphenylisooctyl phosphite, continue stirring, and react 1 to 2 hours, then add lauric acid soap, glucomannan, baicalin, cinnamate and coumarin ester to obtain an intumescent flame retardant.

Embodiment 3

[0033] An intumescent flame retardant comprising the following components in parts by weight:

[0034] 10 parts of lauric acid soap, 30 parts of glucomannan, 60 parts of triaryl phosphate, 30 parts of phenolic resin, 20 parts of aminomethylphosphonic acid, 10 parts of tetravinyltetramethylcyclotetrasiloxane, zinc borate 15 parts, 3 parts of baicalin, 5 parts of cinnamate, 5 parts of coumarin ester and 10 parts of diphenylisooctyl phosphite.

[0035] The preparation method of above-mentioned intumescent flame retardant comprises the following steps:

[0036] Mix triaryl phosphate and phenolic resin according to the formula, stir evenly, then add aminomethylphosphonic acid, tetravinyltetramethylcyclotetrasiloxane, zinc borate and diphenylisooctyl phosphite, continue stirring, and react 1 to 2 hours, then add lauric acid soap, glucomannan, baicalin, cinnamate and coumarin ester to obtain an intumescent flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com