Sustained release agricultural plastic mulch used for preventing and controlling bacterial wilt and preparation method thereof

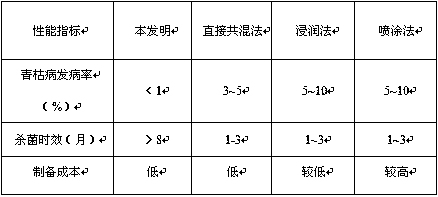

A technology of plastic mulch and agricultural mulch, which is applied in botany equipment and methods, applications, plant protection, etc., can solve the problems of plant disease and insect pest infection, yield and quality reduction, easy leakage of garlic oil, etc., and achieve good antibacterial effect , slow down the precipitation, reduce the effect of bacterial wilt disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

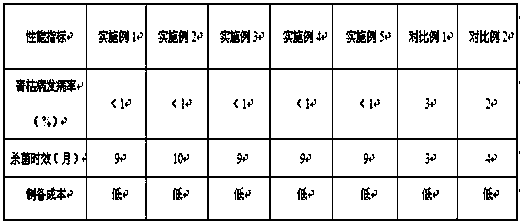

Examples

Embodiment 1

[0035] The components of the agricultural mulch film are calculated in parts by weight, including: 64 parts of matrix resin, 30 parts of sustained-release capsules, 4 parts of talcum powder, 1 part of monoglyceride, and 1 part of polyethylene wax;

[0036] The raw materials of the sustained-release capsule are calculated in parts by weight, including: 20 parts of garlic oil, 30 parts of hydrotalcite, 47 parts of modified starch, and 3 parts of cross-linking agent;

[0037] The matrix resin is ethylene-vinyl acetate copolymer; the crosslinking agent is succinic dialdehyde;

[0038] The concrete steps of preparation are:

[0039] (1) Mix garlic oil and ethanol at a volume ratio of 4:1, stir and dissolve, use an atomizing device to atomize the mixed solution into 0.3mm fine droplets, and spray it between the hydrotalcite layers through a spray gun. Cooling and solidification during the flight form a solid-liquid two-phase particle jet stream, which is sprayed onto the hydrotalci...

Embodiment 2

[0045] The components of the agricultural mulch film are calculated in parts by weight, including: 77 parts of matrix resin, 20 parts of sustained-release capsules, 2 parts of talcum powder, 0.5 parts of monoglyceride, and 0.5 parts of polyethylene wax;

[0046] The raw materials of the sustained-release capsule are calculated in parts by weight, including: 20 parts of garlic oil, 30 parts of hydrotalcite, 49 parts of modified starch, and 1 part of crosslinking agent;

[0047] The matrix resin is polyvinyl chloride; the crosslinking agent is glutaraldehyde;

[0048] The concrete steps of preparation are:

[0049] (1) Mix garlic oil and ethanol at a volume ratio of 4:1, stir and dissolve, use an atomizing device to atomize the mixed solution into 0.8mm fine droplets, and spray it between the hydrotalcite layers through a spray gun. Cooling and solidification during the flight form a solid-liquid two-phase particle jet stream, which is sprayed onto the hydrotalcite layer for im...

Embodiment 3

[0055] The components of the agricultural mulch film are calculated in parts by weight, including: 70 parts of matrix resin, 24 parts of sustained-release capsules, 4 parts of talcum powder, 1 part of monoglyceride, and 1 part of polyethylene wax;

[0056] The components of the sustained-release capsule are calculated in parts by weight, including: 10 parts of garlic oil, 25 parts of hydrotalcite, 64 parts of modified starch, and 1 part of crosslinking agent;

[0057] The matrix resin is polypropylene; the crosslinking agent is formaldehyde;

[0058] The concrete steps of preparation are:

[0059] (1) Mix garlic oil and ethanol at a volume ratio of 3:1, stir and dissolve, use an atomizing device to atomize the mixed solution into 0.8mm fine droplets, and spray it between the hydrotalcite layers through a spray gun. Cooling and solidification during the flight form a solid-liquid two-phase particle jet stream, which is sprayed onto the hydrotalcite layer for impact, bonding, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com