A method for preparing synthesis gas by pyrolyzing biomass mixed with high ash papermaking sludge

A papermaking sludge and biomass technology, applied in the direction of biofuel, special dry distillation, coking oven, etc., can solve the problem of easy corrosion of tar and blockage of fuel pipelines, downstream equipment of filtration devices, high tar content in gas production, and cannot be really removed tar and other problems, to achieve the effect of reducing utilization, increasing the yield of syngas, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

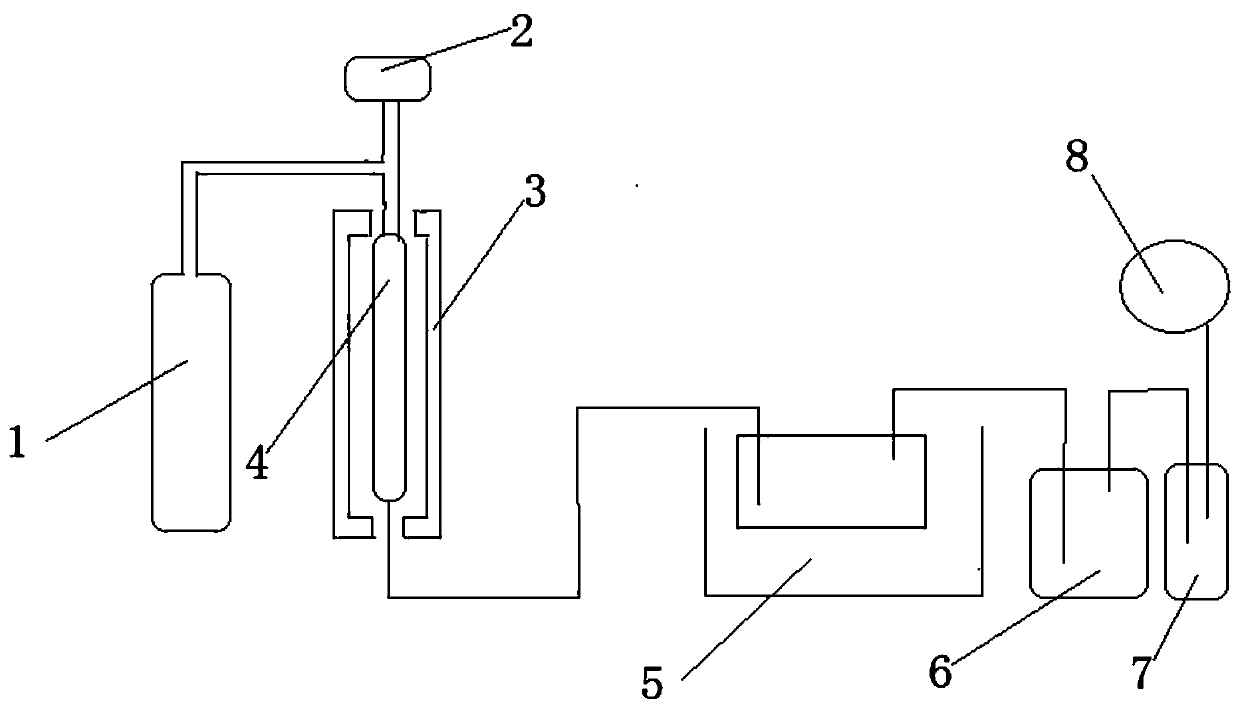

[0028] according to figure 1 Assembled system shown.

[0029] A method for preparing synthesis gas by pyrolyzing biomass blended high-ash papermaking sludge, comprising the following steps:

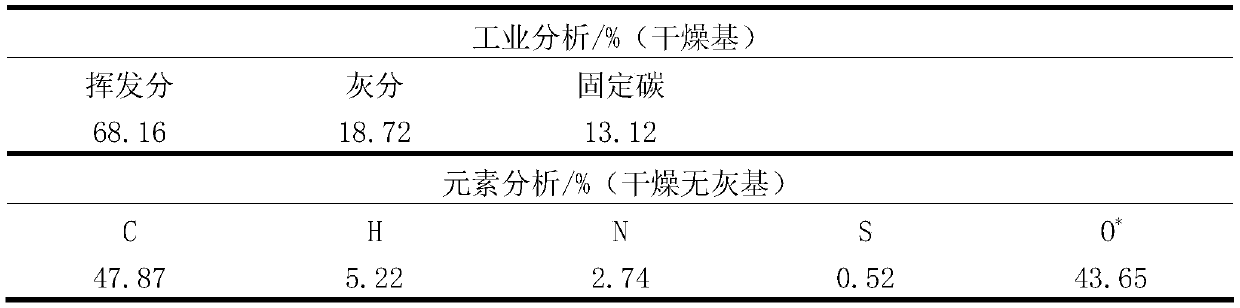

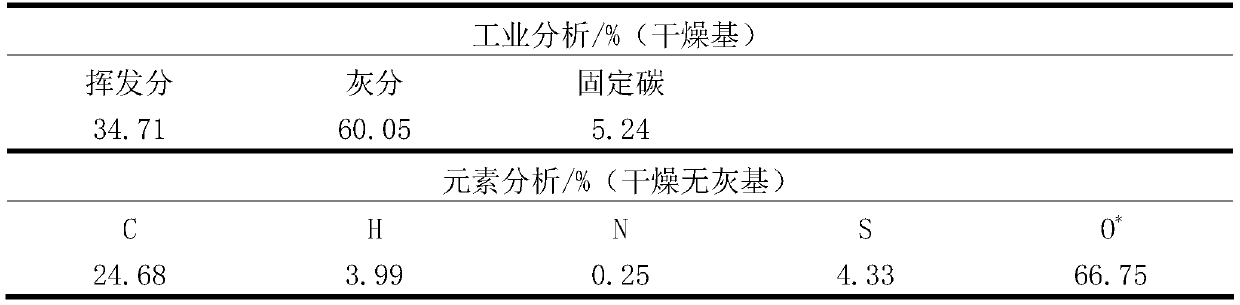

[0030] Step 1, dry and sieve the biomass and sludge respectively to obtain biomass fine powder with a particle size of 0.2-0.45mm and sludge fine powder with a particle size of less than 0.125mm, which are selected according to the mass ratio of 3:1 The biomass fine powder and the sludge fine powder are mixed to obtain a mixed fine powder, which is sealed and stored for later use;

[0031] Step 2, put the mixed fine powder in the feeder, open the nitrogen cylinder, adjust the pressure valve, control the pressure at 0.1MPa, control the flow rate of nitrogen to 150ml / min, wait until the air in the gas path is exhausted, open the tube type The target temperature of the furnace is set at 900°C. After the temperature in the furnace rises to the target temperature, the mixed fine powder in th...

Embodiment 2

[0041] Except that the temperature of the pipe line in step 2 is set to 700° C., the others are the same as in embodiment 1.

[0042] The synthesis gas components prepared in Example 2 were detected, and the data are shown in Table 4.

[0043] Table 4 The gas composition table prepared by embodiment 2

[0044]

[0045] The control group is: under the same conditions, the weighted average of the gas content obtained by pyrolyzing the biomass fine powder and sludge fine powder of the same quality respectively.

[0046] The results show that the yield of hydrogen is 29.6% higher than that of pyrolysis alone, the yield of carbon monoxide is 3.0% lower than that of pyrolysis alone, the yield of methane is 14.2% lower than that of pyrolysis alone, and the yield of carbon dioxide is 15.5% higher than that of pyrolysis alone. Rate 0.128Nm 3 / kg, which is 9.6% higher than that of pyrolysis alone, and the tar yield is 31.4g / kg, which is 20.9% lower than that of pyrolysis alone.

Embodiment 3

[0048] Except that the mass ratio of biomass fine powder and sludge fine powder is 1:1, the rest are the same as in Example 1.

[0049] The synthesis gas components prepared in Example 3 were detected, and the data are shown in Table 5.

[0050] The gas composition table that table 5 embodiment 3 prepares

[0051]

[0052] The control group is: under the same conditions, the weighted average of the gas content obtained by pyrolyzing the biomass fine powder and sludge fine powder of the same quality respectively.

[0053]The results show that the yield of hydrogen is 29.0% higher than that of pyrolysis alone, the yield of carbon monoxide is 64.7% higher than that of pyrolysis alone, the yield of methane is 24.5% lower than that of pyrolysis alone, and the yield of carbon dioxide is 64.3% higher than that of pyrolysis alone. Rate 0.295Nm 3 / kg, which is 49.6% higher than that of pyrolysis alone, and the tar yield is 4.6g / kg, which is 34.2% lower than that of pyrolysis alone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com