A kind of highly thermally conductive active composite packaging material and preparation method thereof

A technology of packaging materials and aluminum composite materials, applied in the field of high thermal conductivity active composite packaging materials and its preparation, can solve the problems of difficult connection between diamond and aluminum, insufficient bonding strength, low expansion coefficient, etc., and achieve good interface bonding and low thermal expansion coefficient, high thermal conductivity, and the effect of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

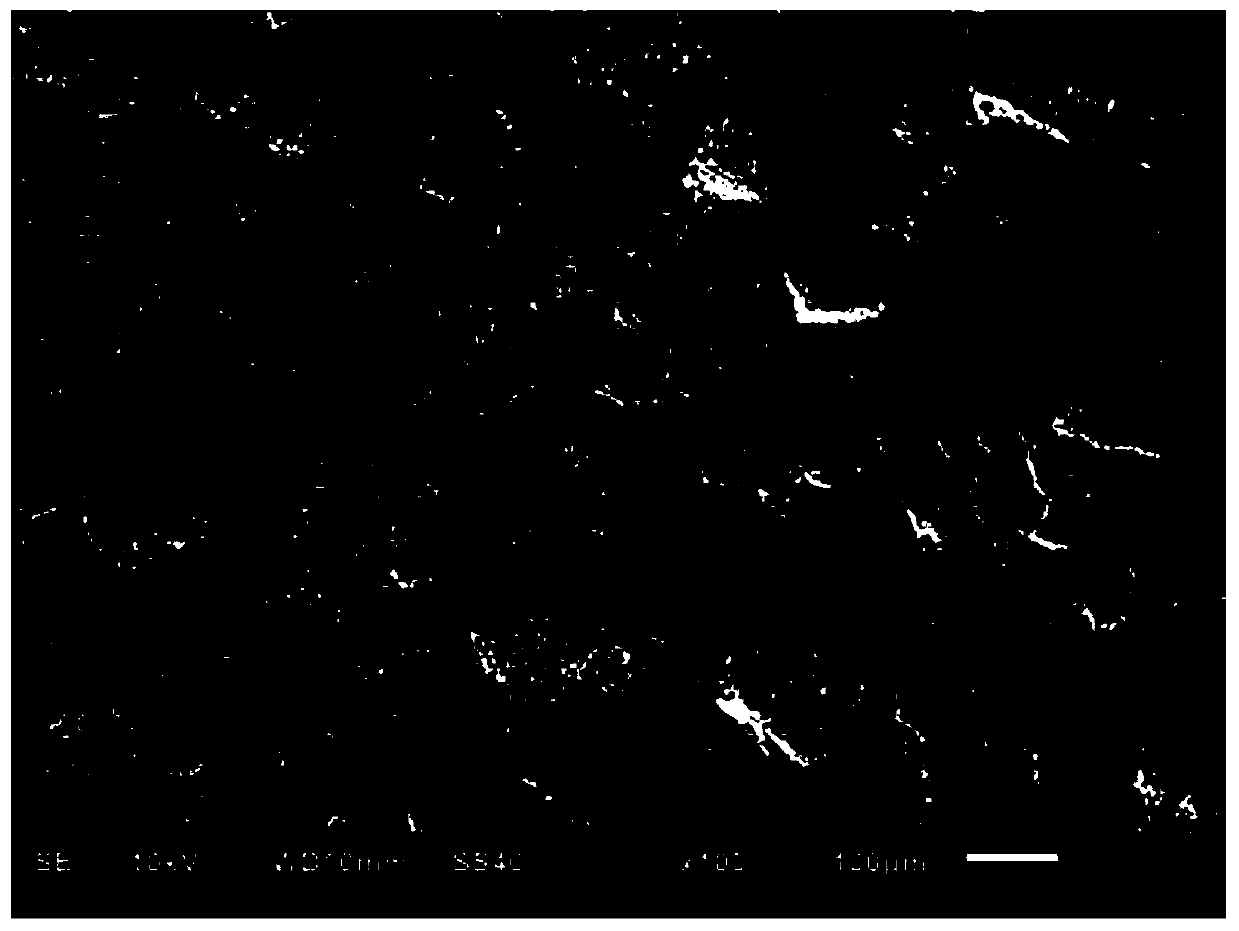

Embodiment 1

[0038] Preparation of Active Solder SnAg by Vacuum Air Atomization 4 Ti 4Powder, the particle size of which is 20 μm, the particle size of diamond particle is 200 μm, and the particle size of aluminum powder is 20 μm. The volume percentages were 60%, 1%, 39% diamond particles, SnAg 4 Ti 4 Powder and aluminum powder were mixed and ball milled for 60 minutes, and the mixed powder after ball milling was put into a spark plasma sintering furnace for sintering to obtain a diamond / aluminum / active solder composite material. The sintering temperature is 600°C, the sintering pressure is 50MPa, the heating rate is 100°C / min, the heat preservation is 5min, and the atmosphere is vacuum. The diamond / aluminum / active solder composite material prepared by this process has a thermal conductivity of 703W / m K and a linear expansion coefficient of 7.9×10 -6 K, the density is 99.5%.

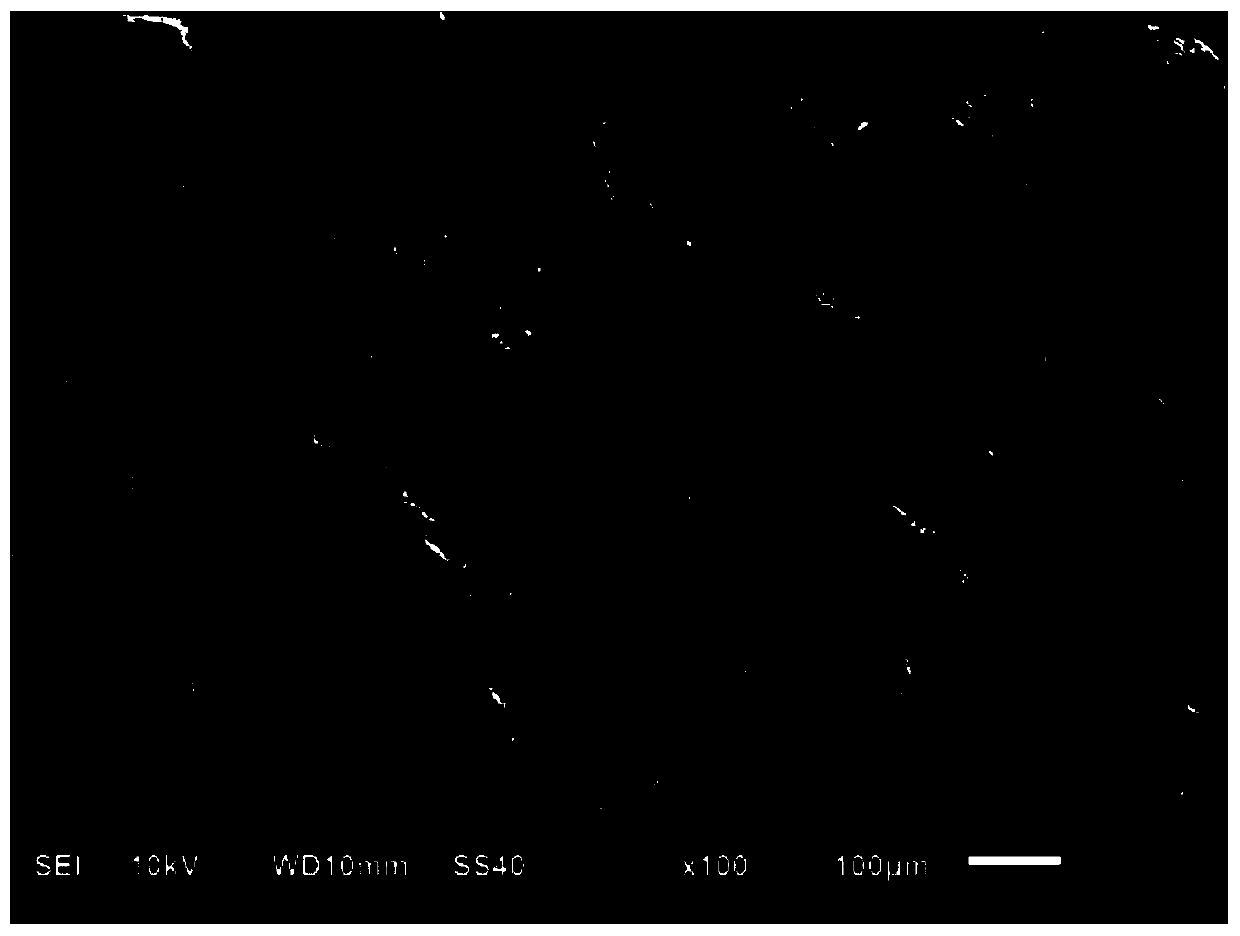

Embodiment 2

[0040] The processing condition of the present embodiment is identical with embodiment 1, only changes active solder SnAg 4 Ti 4 Alloy powder ratio, using 5% SnAg 4 Ti 4 Alloy powder, 58% diamond particles, 37% aluminum powder. The thermal conductivity of the prepared diamond / aluminum composite material is 602W / m·K, and the linear expansion coefficient is 8.5×10 -6 K, the density is 99.7%.

Embodiment 3

[0042] The process conditions of this embodiment are the same as those of Embodiment 1, only the particle size of the aluminum powder is changed, and the size of the aluminum powder is 100 μm. The thermal conductivity of the prepared diamond / aluminum / active solder composite material is 588W / m·K, and the linear expansion coefficient is 8.0×10 -6 K, the density is 98.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com