Real-time lithiation wall processing system used for improving wall conditions of plasma

A processing system and plasma technology, applied in the field of real-time lithiated wall processing systems, can solve the problems of impurity pollution, high recirculation, etc., and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

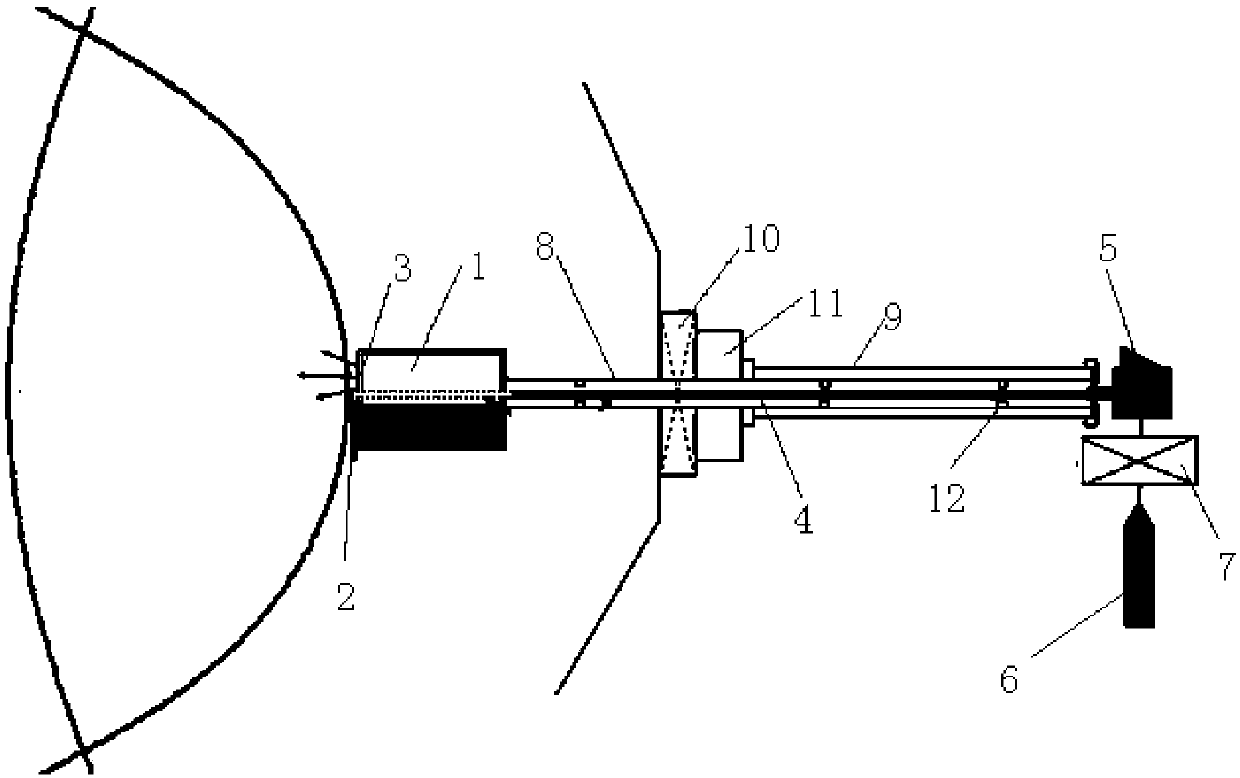

[0022] See attached picture.

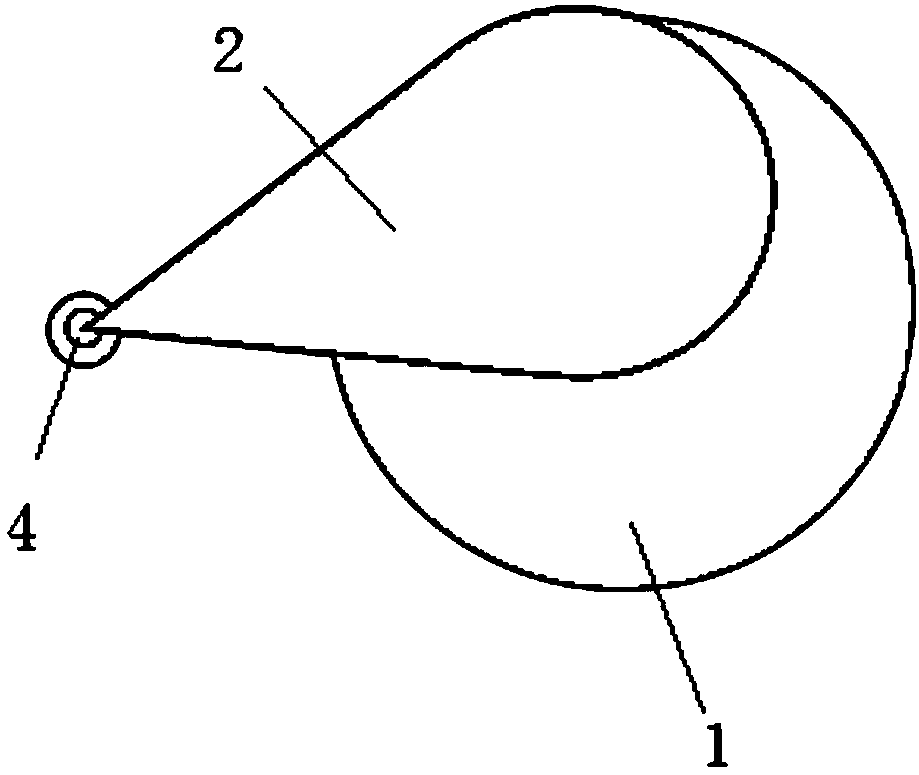

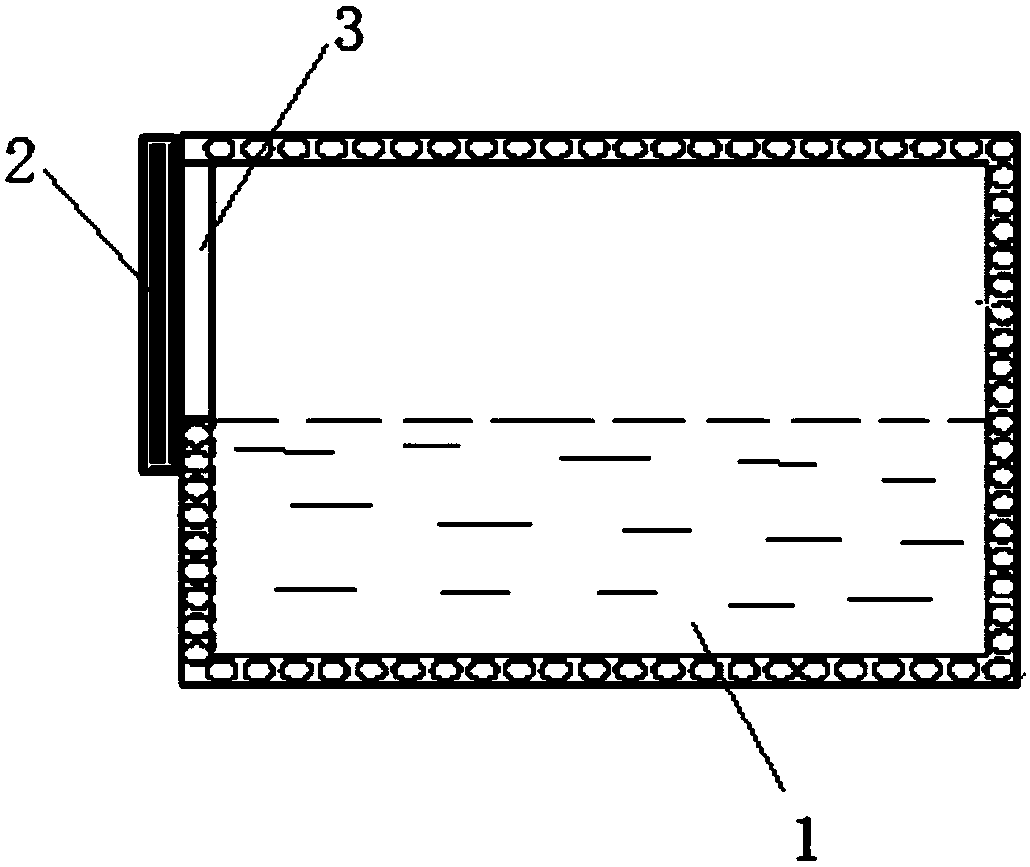

[0023] A real-time lithiated wall treatment system for improving plasma wall conditions, comprising an evaporator 1, a baffle and a control system, and a bellows transmission system, the baffle and the control system including a rotatable baffle 2, The baffle 2 is arranged at the evaporation outlet 3 of the evaporator, the rotating shaft of the baffle 2 extends through the evaporator 1 to the outer end, and the other end of the rotating shaft 4 is equipped with a linear guide 5, the linear The lower end of the introducer 5 is connected to the nitrogen cylinder 6 through a pipeline, and a solenoid valve 7 is arranged in the pipeline. The bellows transmission system includes a support tube 8, and the support tube 8 is sleeved on the rotating shaft 4 at the rear end of the evaporator. The front end of the support tube 8 communicates with the evaporator 1, the rear end of the support tube 8 is covered with a bellows 9, and the front end of the bellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com