A kind of low-silver solder for vacuum electronic device sealing and preparation method thereof

A technology of vacuum electronic devices and silver solder, which is applied in the direction of welding equipment, welding/cutting media/materials, manufacturing tools, etc., to achieve the effect of reducing the electroplating process, small solid-liquid phase temperature difference, and excellent brazing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Its preparation method comprises the following steps:

[0033] 1) Weigh silver (Ag), oxygen-free copper, gallium (Ga) and nickel (Ni) according to the composition ratio. The purity of silver (Ag) and gallium (Ga) is both 99.99% (mass %), and the purity of nickel (Ni) is 99.9% (mass %) or more.

[0034] 2) Vacuum continuous casting: Put the silver, oxygen-free copper, gallium and nickel raw materials weighed above into the horizontal continuous casting furnace, and when the vacuum is lowered to 0.1Pa, raise the temperature. Refining at ℃ for 5-10 minutes, and then drawing at 900-920 ℃, casting speed: 2-4mm / s, cooling water flow rate at 2L / min, continuously casting AgCuGaNi alloy ingots with a thickness of 10mm and a width of 265mm . After the raw materials are completely melted and before refining, you can choose to keep warm for a period of time, and the holding time is 20-40min.

[0035] 3) Solution heat treatment: heat preservation at 690°C to 720°C for 30 to 45 mi...

Embodiment 1

[0041] Weigh 5.0Kg gallium, 42.0Kg silver, 2.0Kg nickel and 51.0Kg copper, put them into the horizontal continuous casting furnace for melting, and evacuate to 1.0×10 -1Pa, heat up, refine at 880°C for 10min, start drawing at 900°C, casting speed 2mm / s, cooling water flow rate 2L / min, the resulting product contains Ag 42.0wt%, Cu 51.0wt%, Ga 5.0wt% , Ni 2.0wt% alloy ingot. Then solution heat treatment at 700°C for 40min; rolling to 0.2mm with a two-roll rolling mill; annealing at 360°C for online stretching and straightening heat treatment, the running speed of the sheet is controlled at 4m / min, and the tension for stretching and straightening is preset to 0.8KN. The elongation is preset to 1.0%. Finally, finish rolling to obtain AgCuGaNi foil-shaped low-silver solder with a thickness of 20 μm and a width of 250 mm.

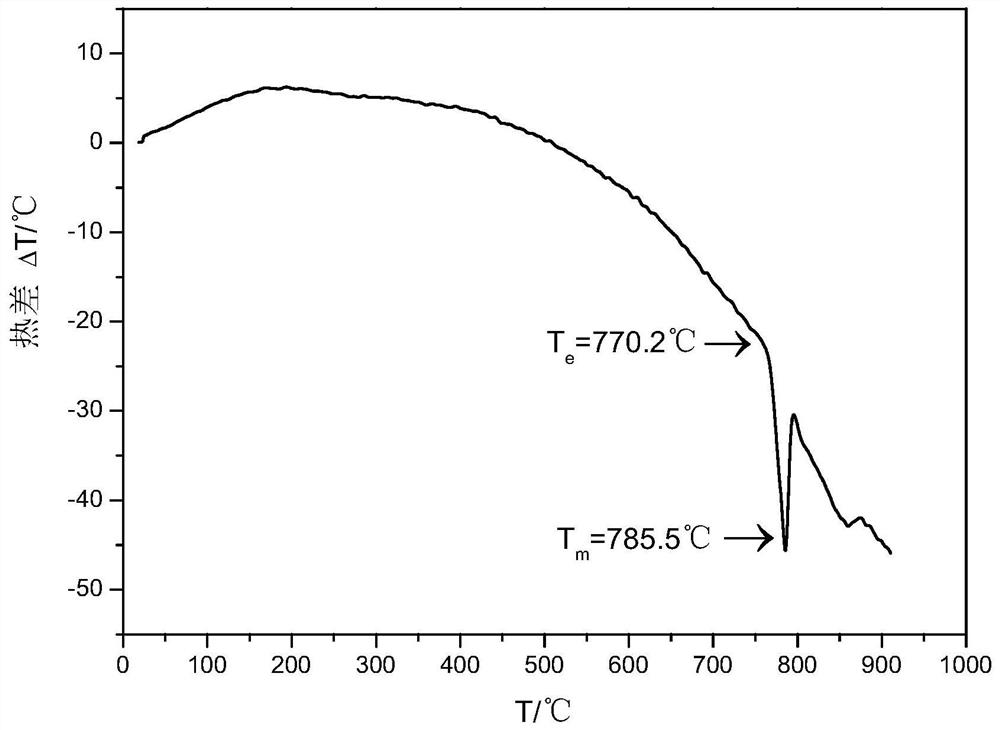

[0042] like figure 1 Shown is the differential thermal curve of the Ag-Cu-Ga-Ni alloy obtained in Example 1. It can be seen from the figure that the melting ...

Embodiment 2

[0045] Weigh 4.0Kg gallium, 44.0Kg silver, 1.5Kg nickel and 50.5Kg copper, put them into a horizontal continuous casting furnace for melting, and vacuumize to 10 -1 Below Pa, heat up, refine at 890°C for 8 minutes, start drawing at 920°C, casting speed 3mm / s, cooling water flow rate 2L / min, the resulting product contains Ag 44.0wt%, Cu 50.5wt%, Ga 4.0wt %, Ni 1.5wt% alloy ingot. Then solution heat treatment at 690°C for 45 minutes; rolling to 0.3mm with a two-roll rolling mill; annealing at 400°C for online stretching and straightening heat treatment, the running speed of the sheet is controlled at 5m / min, and the tension for stretching and straightening is preset to 0.6KN. The elongation is preset to 1.0%. Finally, finish rolling to obtain AgCuGaNi foil-shaped low-silver solder with a width of 20 μm and a width of 250 mm.

[0046] The obtained solder had a solidus temperature of 782°C and a liquidus temperature of 805°C. The brazing material is used to carry out the sealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com