Hydrosilylation reaction using recyclable platinum compound as catalyst

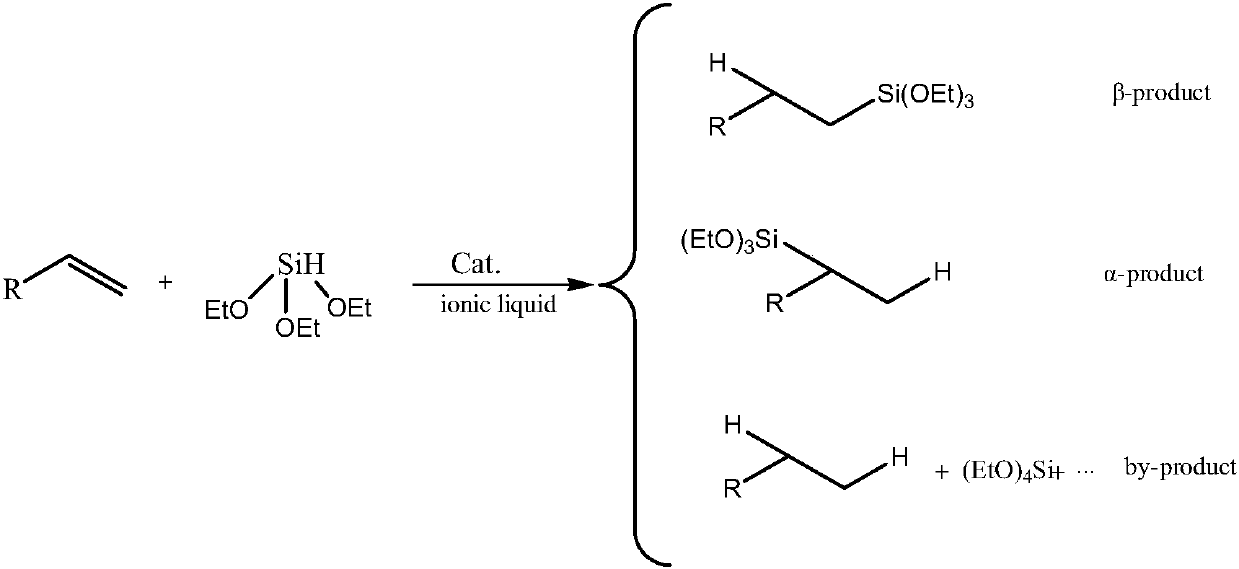

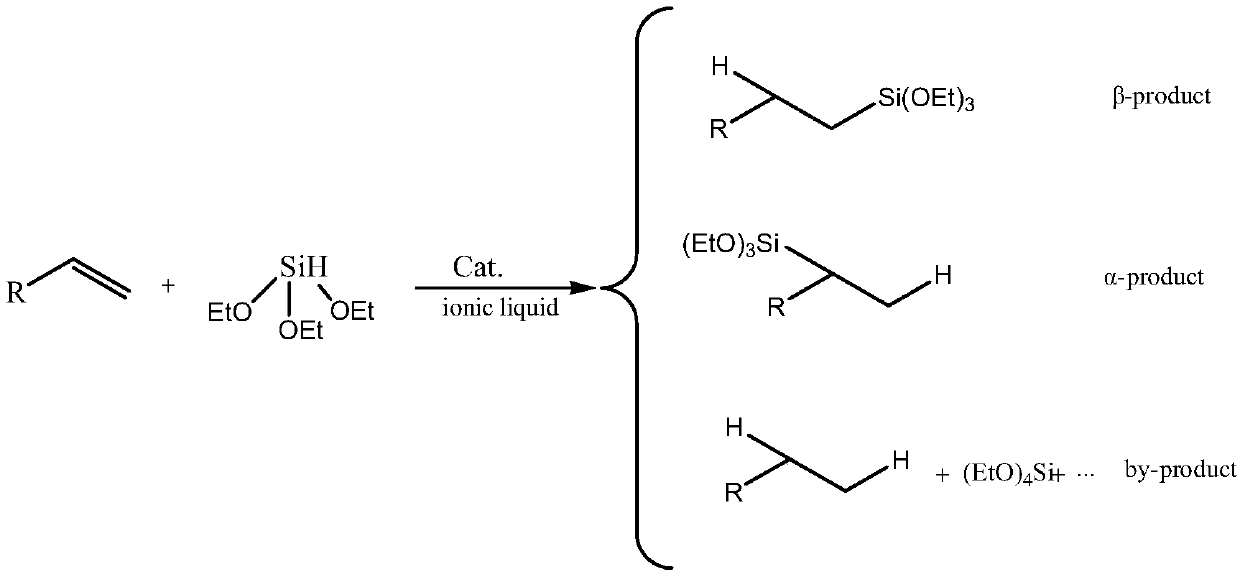

A technology of hydrosilylation reaction and platinum compound is applied in the field of highly selective bis[platinum dichloride] as a catalyst, which can solve the problem that the catalytic system is difficult to separate and recycle, it is difficult to apply to industrialization, and the catalytic reaction activity is not high. High-level problems, to achieve the effect of high selectivity, high conversion rate, and simple product separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

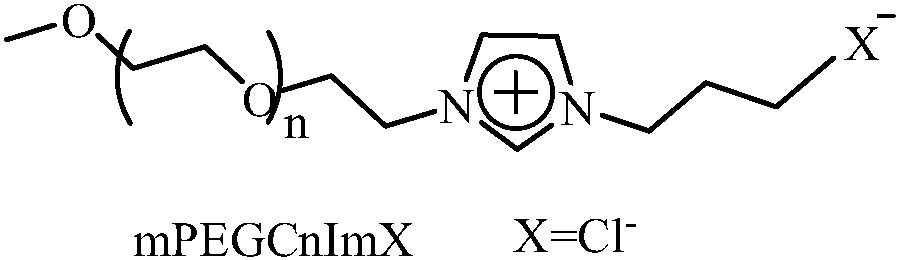

Embodiment 1

[0021] Catalyst 1 preparation: under the protection of argon, use a low-temperature constant temperature reactor, the reaction temperature is controlled at -78 ° C, and n-butyllithium ( n BuLi 3.0mmol, 15% n-hexane solution) was added dropwise to the CH of mPEG (350)MImCl (3.0mmol) 2 Cl 2 (20mL) solution (in advance with P 4 o 10 Dry CH 2 Cl 2 )middle. After the dropwise addition, continue to stir at -78°C for 45 minutes at the reaction temperature, and then use about 20 minutes to mix the Ph 2 PCl (3.0 mmol) was added dropwise to the previous reaction solution. After the dropwise addition was completed, stirring was continued for 20 minutes, the reaction temperature was slowly raised to room temperature, and the reaction was completed overnight after stirring. After the product was washed three times with deoxygenated water (3*10mL), the organic phase was washed with Na 2 SO 4 Drying, spin-drying solvent, obtain solid product quantitatively, in N 2 Under protection, ...

Embodiment 2

[0024] Catalyst 2 preparation: under the protection of argon, use a low temperature constant temperature reactor, the reaction temperature is controlled at -78 ° C, and n-butyllithium ( n BuLi 3.0mmol, 15% n-hexane solution) was added dropwise to the CH of mPEG (550)MImCl (3.0mmol) 2 Cl 2 (20mL) solution (in advance with P 4 o10 Dry CH 2 Cl 2 )middle. After the dropwise addition, continue to stir at -78°C for 45 minutes at the reaction temperature, and then use about 20 minutes to mix the Ph 2 PCl (3.0 mmol) was added dropwise to the previous reaction solution. After the dropwise addition was completed, stirring was continued for 20 minutes, the reaction temperature was slowly raised to room temperature, and the reaction was completed overnight after stirring. After the product was washed three times with deoxygenated water (3*10mL), the organic phase was washed with Na 2 SO 4 Drying, spin-drying solvent, obtain solid product quantitatively, in N 2 Under protection, in...

Embodiment 3

[0027] Catalyst 3 preparation: under the protection of argon, use a low-temperature constant temperature reactor, the reaction temperature is controlled at -78 ° C, and n-butyllithium ( n BuLi 3.0mmol, 15% n-hexane solution) was added dropwise to the CH of mPEG (750)MImCl (3.0mmol) 2 Cl 2 (20mL) solution (in advance with P 4 o 10 Dry CH 2 Cl 2 )middle. After the dropwise addition, continue to stir at -78°C for 45 minutes at the reaction temperature, and then use about 20 minutes to mix the Ph 2 PCl (3.0 mmol) was added dropwise to the previous reaction solution. After the dropwise addition was completed, stirring was continued for 20 minutes, the reaction temperature was slowly raised to room temperature, and the reaction was completed overnight after stirring. After the product was washed three times with deoxygenated water (3*10mL), the organic phase was washed with Na 2 SO 4 Drying, spin-drying solvent, obtain solid product quantitatively, in N 2 Under protection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com