Multifunctional bio-organic fertilizer and application method thereof

A bio-organic fertilizer and multi-functional technology, applied in the direction of organic fertilizer, application, phosphate fertilizer, etc., can solve the problems of low crop quality and yield, achieve the effect of increasing species diversity, avoiding loss, and ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

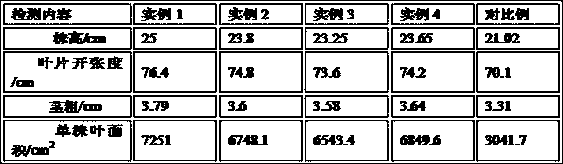

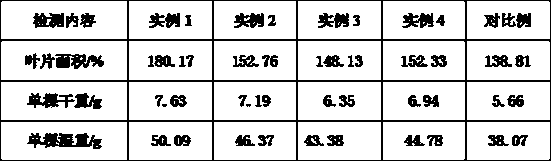

Examples

example 1

[0024]Pour chitosan with a deacetylation degree of 95% and water into a beaker at a mass ratio of 1:30, stir and mix with a glass rod for 15 minutes, then let it stand for swelling at room temperature for 4 hours, and then move the beaker into a digital display to measure speed and constant temperature With a magnetic stirrer, at a temperature of 85°C and a speed of 500r / min, stir and dissolve at a constant temperature for 60 minutes, then cool naturally to room temperature to obtain chitosan liquid; Mix the chitosan with water and pour it into a three-necked flask, let it swell for 4 hours, then add chitosan enzyme with 0.03 times the mass of chitosan in the three-necked flask, at a temperature of 40°C and a speed of 600r / min, After stirring and reacting at a constant temperature for 5 hours, inactivate the enzyme at 95°C for 15 minutes, and cool down to room temperature naturally to obtain a small molecule chitosan degradation liquid; in parts by weight, take 100 parts of chi...

example 2

[0026] Then mix chitosan with a deacetylation degree of 95% and water according to the mass ratio of 1:20 and pour it into a three-necked flask. , at a temperature of 40°C and a rotation speed of 600r / min, after a constant temperature stirring reaction for 5 hours, then at a temperature of 95°C, an enzyme-inactivating treatment was performed for 15 minutes, and after natural cooling to room temperature, a small molecular chitosan degradation solution was obtained; In parts by weight, 40 parts of small molecular chitosan degradation liquids were successively taken, and mixed with a mixer for 60 min at a speed of 400 r / min to obtain component A; in parts by weight, 15 parts of vermicompost were added successively in the fermenter, 15 parts of biogas slurry, 10 parts of activated sludge from the secondary settling tank of domestic sewage treatment plant, 30 parts of cow dung, 15 parts of humic acid, 15 parts of blue-green algae, 40 parts of water, at a temperature of 35°C and a sp...

example 3

[0028] Pour chitosan with a deacetylation degree of 95% and water into a beaker at a mass ratio of 1:30, stir and mix with a glass rod for 15 minutes, then let it stand for swelling at room temperature for 4 hours, and then move the beaker into a digital display to measure speed and constant temperature With a magnetic stirrer, at a temperature of 85° C. and a rotating speed of 500 r / min, stir and dissolve at a constant temperature for 60 minutes, then cool naturally to room temperature to obtain a chitosan solution; in parts by weight, take 100 parts of the chitosan solution successively, Stir and mix with a mixer at a speed of 400r / min for 60min to obtain component A; in parts by weight, add 15 parts of vermicompost, 15 parts of biogas slurry, and 10 parts of activated sludge from the secondary sedimentation tank of domestic sewage treatment plant in the fermentation tank , 30 parts of cow dung, 15 parts of humic acid, 15 parts of blue-green algae, 40 parts of water, at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com