Silicon nitride ceramic and preparation method thereof

A technology of silicon nitride ceramics and tetramethylammonium hydroxide, which is applied in the field of silicon nitride ceramics and its preparation, can solve the problems of excessively high requirements for silicon nitride raw materials, affecting high-temperature performance of materials, and extremely high chemical activity requirements, and achieves Low production cost, lower sintering temperature, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

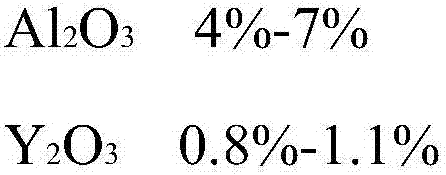

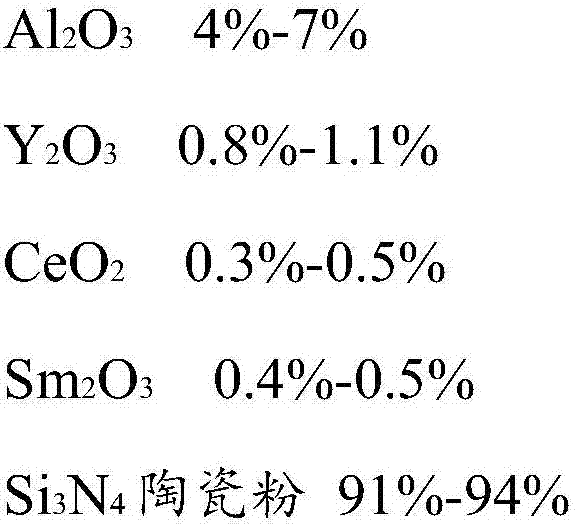

[0020] (1) Preparation of composite granulated powder: weigh each component according to mass percentage, where the composite mixed powder includes Al 2 O 3 : 6%, Y 2 O 3 : 0.8%, CeO 2 : 0.3%, Sm 2 O 3 : 0.4%, Si 3 N 4 Ceramic powder: 92.5%, then add crystalline tetramethylammonium hydroxide and PVB ethanol solution, the mass of tetramethylammonium hydroxide is 0.8% of the composite mixed powder, the mass of PVB ethanol solution and the composite mixed powder The ratio is 0.8-1, and the mass concentration of PVB in the ethanol solution of PVB is 1%-2%. Load the above components into a stirring ball mill using ethanol as the ball milling medium for ball milling, ball milling for 18-20 hours, spray granulating the powder after ball milling, vacuum degree -0.2MPa, drying temperature 100°C, time 2 hour;

[0021] (2) Preliminary preparation of blank: The composite granulated powder is pressed into a shape under a 100T hydraulic press, and pressed at a pressure of 1T per square centime...

Embodiment 2

[0026] (1) Preparation of composite granulated powder: weigh each component according to mass percentage, where the composite mixed powder includes Al 2 O 3 : 4%, Y 2 O 3 : 1.1%, CeO 2 : 0.5%, Sm 2 O 3 : 0.5%, Si 3 N 4 Ceramic powder: 93.9%, then add the ethanol solution of crystalline tetramethylammonium hydroxide and PVB, the mass of tetramethylammonium hydroxide is 0.9% of the composite mixed powder, the mass of the ethanol solution of PVB and the composite mixed powder The ratio is 0.9:1, and the mass concentration of PVB in the ethanol solution of PVB is 1%-2%. Load the above components into a stirring ball mill using ethanol as the ball milling medium for ball milling, ball milling for 18-20 hours, spray granulating the powder after ball milling, vacuum degree -0.1MPa, drying temperature 120°C, time 2 hour;

[0027] (2) Preliminary preparation of blank: The composite granulated powder is pressed into a shape under a 100T hydraulic press, and pressed at a pressure of 1T per ...

Embodiment 3

[0032] (1) Preparation of composite granulated powder: weigh each component according to mass percentage, where the composite mixed powder includes Al 2 O 3 : 5%, Y 2 O 3 : 0.9%, CeO 2 : 0.4%, Sm 2 O 3 : 0.5%, Si 3 N 4 Ceramic powder: 93.2%, then add crystalline tetramethylammonium hydroxide and PVB ethanol solution, the mass of tetramethylammonium hydroxide is 1.0% of the composite mixed powder, the mass of PVB ethanol solution and the composite mixed powder The ratio is 0.8:1, and the mass concentration of PVB in the ethanol solution of PVB is 1%-2%. Load the above components into a stirring ball mill using ethanol as the ball milling medium for ball milling, ball milling for 18-20 hours, spray granulating the powder after ball milling, vacuum degree -0.1MPa, drying temperature 110°C, time 4 hour;

[0033] (2) Preliminary preparation of blank: The composite granulated powder is pressed into a shape under a 100T hydraulic press, and pressed at a pressure of 1T per square centime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com