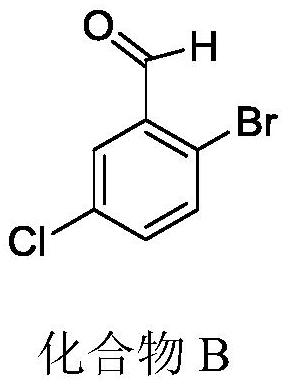

A kind of preparation method of 2-bromo-5-chlorobenzaldehyde

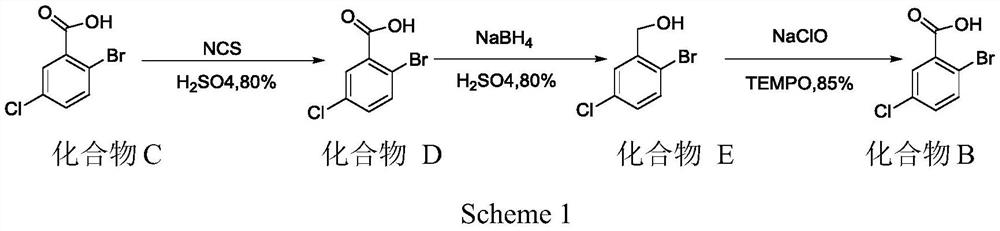

A technology of chlorobenzaldehyde and bromosuccinimide, applied in the field of pharmaceutical synthesis, can solve problems such as low total yield, long reaction steps, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

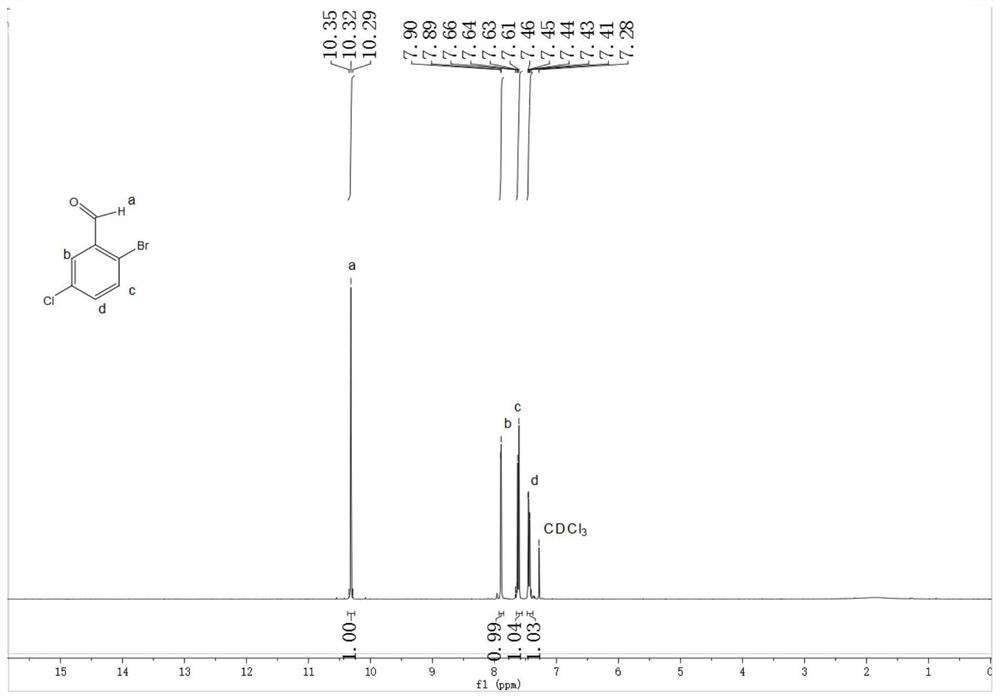

Examples

Embodiment 1

[0035] Put concentrated sulfuric acid (mass fraction 98%, 150mL) into the reaction kettle and stir to lower the temperature, control the temperature of the system to ≤10°C, slowly add compound A liquid (3-chlorobenzaldehyde, 0.5mol) dropwise, after the addition is complete, add an appropriate amount of catalyst I 2 (0.236-2.36mmol, the present embodiment is 30mg), add 3-chlorobenzaldehyde and catalyst I 2 When there is a relatively obvious exothermic phenomenon, it is necessary to control the reaction temperature of the system to ≤10°C;

[0036] System temperature control ≤ 15°C, add NBS (N-bromosuccinimide, 0.5mol) in batches for 5-10 times;

[0037] Insulate and react for 2 hours, slowly rise to 25°C, and then stir and react for 1 hour. GC detects that the content of 3-chlorobenzaldehyde in the raw material is ≤1%, and the reaction solution is post-processed and purified to obtain 98 g of needle-like off-white solid Compound B with a purity of 98.0%. Yield 90.1%.

Embodiment 2

[0039] Put concentrated sulfuric acid (mass fraction 98%, 100mL) into the reaction kettle and stir to lower the temperature, control the temperature of the system to ≤10°C, slowly add compound A liquid (3-chlorobenzaldehyde, 0.5mol) dropwise, after the addition is complete, add an appropriate amount of catalyst I 2 (0.236-2.36mmol, the present embodiment is 31.8mg), add 3-chlorobenzaldehyde and catalyst I 2 When there is a relatively obvious exothermic phenomenon, it is necessary to control the reaction temperature of the system to ≤10°C;

[0040] System temperature control ≤ 15°C, add NBS (N-bromosuccinimide, 0.5mol) in batches for 5-10 times;

[0041] Insulate and react for 2 hours, slowly raise to 25°C, and then stir for 1 hour. GC detects that the content of 3-chlorobenzaldehyde in the raw material is ≤1%, and the reaction solution is post-processed and purified to obtain 97.9 g of needle-like off-white solid compound B with a purity of 97.5%. , yield 90.0%.

Embodiment 3

[0043] Put concentrated sulfuric acid (98% mass fraction, 80mL) into the reaction kettle and stir to lower the temperature, control the temperature of the system to ≤10°C, slowly add compound A liquid (3-chlorobenzaldehyde, 0.5mol) dropwise, after the addition is complete, add an appropriate amount of catalyst I 2 (0.236-2.36mmol, the present embodiment is 63.5mg), add 3-chlorobenzaldehyde and catalyst I 2 When there is a relatively obvious exothermic phenomenon, it is necessary to control the reaction temperature of the system to ≤10°C;

[0044] System temperature control ≤ 15°C, add NBS (N-bromosuccinimide, 0.55mol) in batches for 5-10 times;

[0045] Insulate and react for 3 hours, slowly raise to 28°C, and then stir for 4 hours. GC detects that the content of 3-chlorobenzaldehyde in the raw material is ≤1%, and the reaction solution is post-processed and purified to obtain 98.5g of needle-like off-white solid Compound B with a purity of 98%. , yield 90.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com