Preparation method of cinnamyl cinnamate

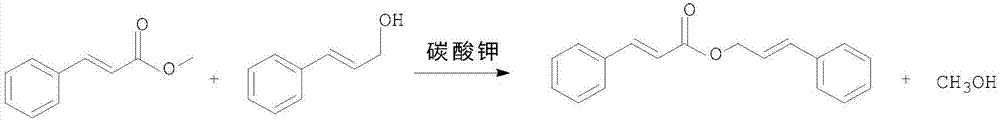

A technology of cinnamic acid and methyl laurate, which is applied in the field of preparation of cinnamic acid, can solve problems such as difficult crystallization, complex process, and many by-products, so as to avoid side reaction products, shorten reaction time, and improve conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

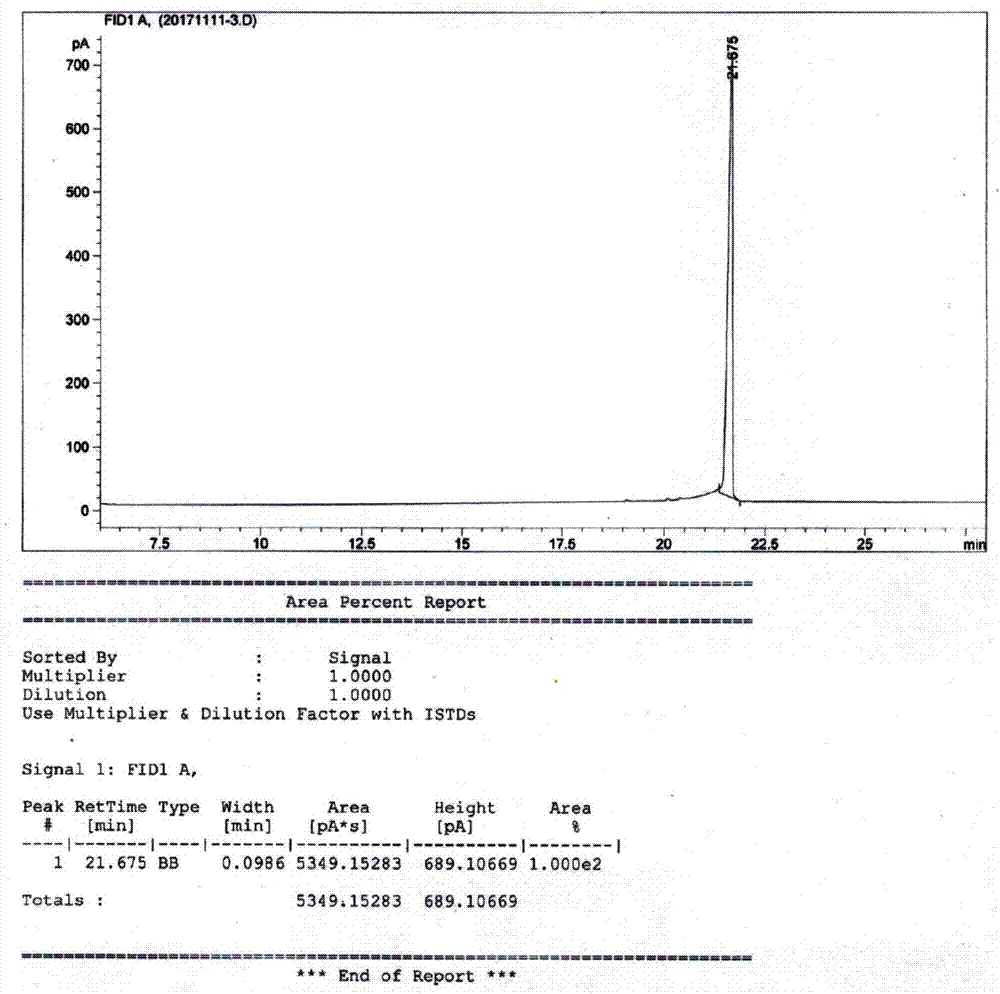

Image

Examples

Embodiment 1

[0055] (1) Reaction

[0056] In an oil bath, 117.36g of methyl laurate, 194.40g of cinnamon and 8.58g of potassium carbonate were put into a 500ml three-necked flask, and the resulting mixture was heated to an internal temperature of 120°C under stirring, and methanol began to distill out. After 1 hour, the reaction temperature rose to 160°C and stopped heating, and cooled to 80°C to obtain a reaction solution containing cinnamic acid;

[0057] (2) Washing and recycling

[0058] Add 300g of ethyl acetate and 150g of water to the reaction solution containing cinnamic acid obtained in step (1), stir and separate layers, and after separating the water layer, continue to add 150g of water to the oil layer to wash to neutrality, separate the water layer, and heat to recover acetic acid Ethyl 264g, changed to vacuum distillation at a pressure of 0.1KPa and a temperature of 205°C, and a fraction of 207.6g was collected, which was the crude cinnamic acid ester;

[0059] (3) crystall...

Embodiment 2

[0063] (1) Reaction

[0064] In an oil bath, put 117.36g of methyl laurate, 194.40g of cinnamon alcohol and 5.87g of potassium carbonate into a 500ml three-necked flask, and the resulting mixture was heated to an internal temperature of 120°C under stirring, and methanol began to distill out. After 1.5 hours, the reaction temperature rose to 160°C and stopped heating, and cooled to 80°C to obtain a reaction solution containing cinnamic acid;

[0065] (2) Washing and recycling

[0066] Add 300g of ethyl acetate and 150g of water to the reaction solution containing cinnamic acid obtained in step (1), stir and separate layers, and after separating the water layer, continue to add 150g of water to the oil layer to wash to neutrality, separate the water layer, and heat to recover acetic acid Ethyl 264g, changed to vacuum distillation at a pressure of 0.2KPa and a temperature of 195-205°C, and a fraction of 187.6g was collected, which was the crude cinnamic acid ester;

[0067] (3...

Embodiment 3

[0071] (1) Reaction

[0072] In an oil bath, put 117.36g of methyl laurate, 234.72g of cinnamyl alcohol and 11.74g of potassium carbonate into a 500ml three-necked flask, and the resulting mixture was heated to an internal temperature of 120°C under stirring, and methanol began to distill out. After 3 hours, the reaction temperature rose to 160°C and stopped heating, and cooled to 80°C to obtain a reaction solution containing cinnamic acid;

[0073] (2) Washing and recycling

[0074] Add 350g of ethyl acetate and 180g of water to the reaction solution containing cinnamic acid obtained in step (1), stir and separate layers, and after the water layer is separated, the oil layer continues to be washed with 180g of water to neutrality, and the water layer is separated, and heating reclaims acetic acid Ethyl 284g, changed to vacuum distillation at a pressure of 0.2KPa and a temperature of 195-205°C, and a fraction of 157.6g was collected, which was the crude cinnamon laurate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com