A powder core wire material for preparing corrosion-resistant, anti-fouling, self-lubricating functional coatings and coating preparation method

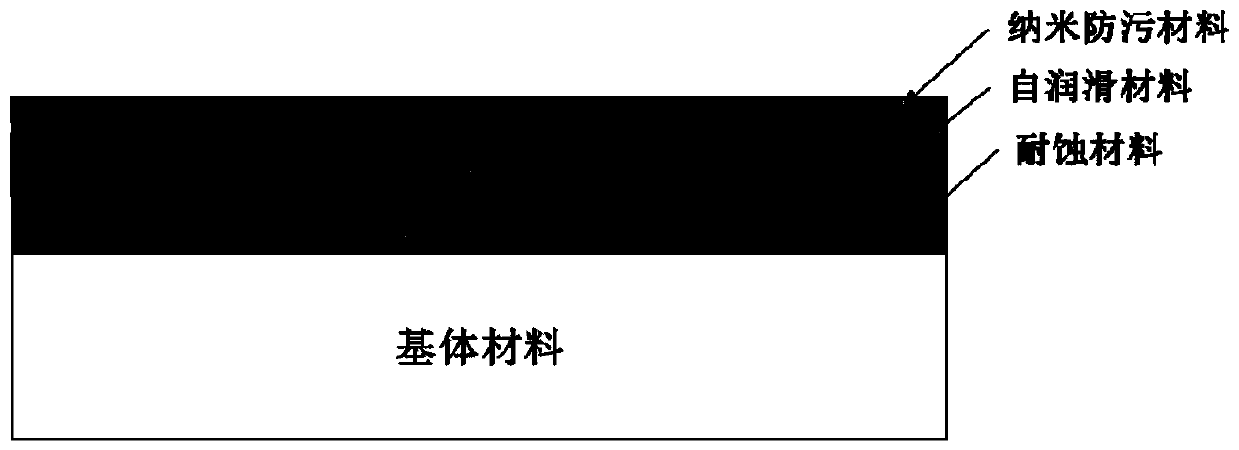

A powder core wire, self-lubricating technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of coating wear, coating failure, marine biological fouling, etc., and achieve good corrosion resistance. And self-lubricating and anti-wear performance, good antifouling performance, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

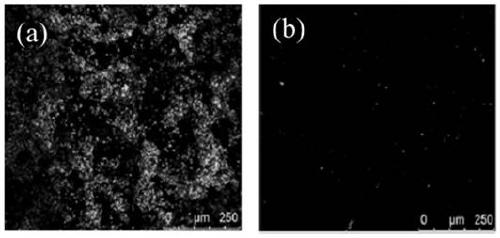

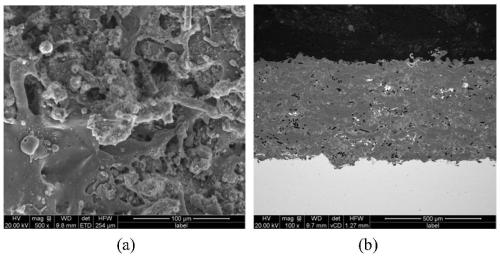

Image

Examples

Embodiment 1

[0033] (1) Preparation of powder core wire:

[0034] The coat of the powder core wire material is an aluminum strip, the width of the aluminum strip is 10mm, and the thickness is 0.3mm. The powder core is a mixed powder of metal pure aluminum, carbon fiber and nano-copper. Among them, the size of the metal pure aluminum is 30-70 μm, and the diameter of the carbon fiber powder is 6 μm , the length is 40-100 μm, the nano-copper powder size is about 300nm, the mass ratio of metal pure aluminum, carbon fiber and nano-copper is 3:4:3, the diameter of the powder core wire is 2mm, and the powder coating rate is 20wt.%.

[0035] (2) Coating preparation:

[0036] Degreasing, derusting and sandblasting are performed on the low-carbon steel base material, and the above-mentioned powder core wire is sprayed onto the surface of the treated low-carbon steel base material by supersonic arc spraying equipment to form a corrosion-resistant, anti-fouling, self-lubricating functional coating Th...

Embodiment 2

[0042] (1) Preparation of powder core wire:

[0043] The coat of the powder core wire material is pure aluminum, the width of the aluminum strip is 8mm, and the thickness is 0.2mm. The powder core is a mixed powder of metallic pure aluminum, molybdenum disulfide and nano-zinc oxide. The size of molybdenum powder is about 10μm, the size of nano-zinc oxide powder is about 200nm, the mass ratio of metallic pure aluminum, molybdenum disulfide and nano-zinc oxide is 3:5:2, the size of powder core wire is 2mm in diameter, and the powder coating rate is 20wt. %.

[0044] (2) Coating preparation:

[0045] Degreasing, derusting and sandblasting are performed on the cast iron base material, and the above powder core wire is sprayed onto the surface of the treated cast iron base material by supersonic arc spraying equipment to form a corrosion-resistant, anti-fouling, self-lubricating functional coating; supersonic arc spraying equipment The spraying process parameters are: current 100...

Embodiment 3

[0049] (1) Preparation of powder core wire:

[0050] The coat of the powder core wire is a nickel-chromium alloy strip with a width of 12mm and a thickness of 0.3mm. The powder core is a mixed powder of metal nickel-chromium alloy powder, carbon fiber and nano-copper, of which the metal nickel-chromium alloy powder is 40-60μm , the carbon fiber powder is 6 μm in diameter, 60-150 μm in length, the size of nano-copper powder is about 300nm, the mass ratio of metal nickel-chromium alloy powder, carbon fiber and nano-copper is 5:3:2, the size of powder core wire is 3mm in diameter, and the powder coating rate 30 wt.%.

[0051] (2) Coating preparation:

[0052] Degreasing, derusting and sandblasting are performed on the low-carbon steel base material, and the above-mentioned powder core wire is sprayed onto the surface of the treated low-carbon steel base material by supersonic arc spraying equipment to form a corrosion-resistant, anti-fouling, self-lubricating functional coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com