Coastal building grouting cement mortar, and production method thereof

A cement mortar and building technology, applied in the field of building materials, can solve the problems of inconvenient construction and engineering quality control, lack of uniform standards for preparation technology, unfavorable production and construction costs, etc., and achieve excellent durability, good economic and social benefits, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

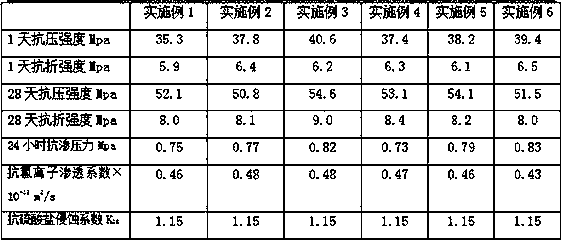

Examples

Embodiment 1

[0045] A coastal building grouting cement mortar, the components are preferably: 30 parts of slag; 50 parts of sulphoaluminate cement clinker; 0.05 parts of composite activator; 4 parts of early strength agent; 0.5 part of water reducing agent; 2 parts of composite coupling agent; 0.5 parts of retarder; 15 parts of water; 150 parts of sand; composite coupling agent is mercaptopropyltrimethoxysilane and phthalate The ester weight ratio is 1:2; the production method comprises the following steps:

[0046] a. Drying: The slag waste is sent to the vertical dryer by the belt conveyor for drying. After drying, the slag waste is sent to the slag waste waste warehouse by the elevator for storage, and the water content is less than 2.8%.

[0047] b. Grinding: Grinding the dried slag waste obtained in step a with a cement mill so that the passing rate through a 100-mesh sieve reaches more than 95%, and the slag waste obtained in step a and the prepared sulphoaluminate cement are cooked ...

Embodiment 2

[0051] A coastal building grouting cement mortar, the components are preferably: 40 parts of slag; 40 parts of sulphoaluminate cement clinker; 0.05 parts of composite activator; 4 parts of early strength agent; 0.5 part of water reducing agent; 3 parts of composite coupling agent; 0.5 part of retarder; 17 parts of water; 160 parts of sand; composite coupling agent is mercaptopropyltrimethoxysilane and phthalate Ester weight ratio is 1:2; Production method is identical with embodiment 1.

Embodiment 3

[0053]A coastal building grouting cement mortar, the components are preferably: 50 parts of slag; 30 parts of sulphoaluminate cement clinker; 0.04 parts of composite activator; 3 parts of early strength agent; 0.4 parts of water reducing agent; 2 parts of composite coupling agent; 0.4 part of retarder; 17 parts of water; 170 parts of sand; composite coupling agent is mercaptopropyltrimethoxysilane and phthalate Ester weight ratio is 1:2; Production method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com