Subdued light glaze for thin ceramic plate

A ceramic thin plate, soft glaze technology, applied to soft glaze. In the field, it can solve the problems that the performance of the glaze needs to be improved, and achieve the effect of improving competitiveness, smooth and delicate surface, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

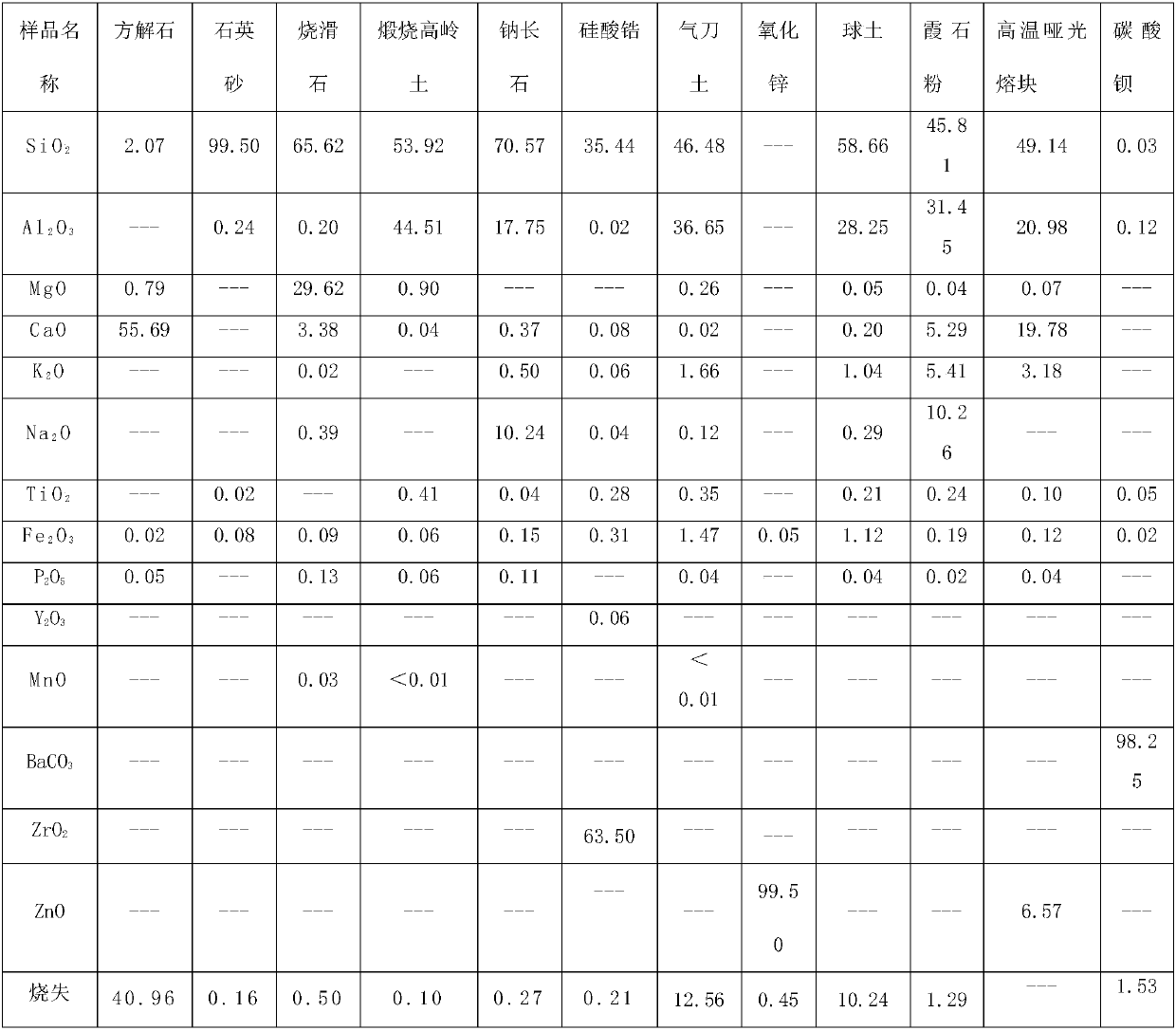

Embodiment 1

[0022] Assuming that the total weight of various raw materials is 4000kg, in terms of weight percentage, the surface glaze includes the following effective components: 20.00% of high-temperature matte frit, 10.54% of air knife soil, 16.98% of calcite, 20.19% of albite, burnt Talc 10.12%, zirconium silicate 7.16%, zinc oxide 4.68% and barium carbonate 10.33%.

[0023] When preparing the surface glaze, it is necessary to mix the above weight percentages with various materials and put them into the ball mill for crushing. Thickness, and a total of 1560kg of water needs to be added during the ball milling process to improve the ball milling efficiency. The final surface glaze: the specific gravity is 1.80-1.83, the flow rate is 45s-65s, and the sieve allowance is 0.3-0.5.

[0024] If the total weight of various raw materials is 4000kg, in terms of weight percentage, the underglaze includes the following effective components: 24.24% of quartz sand, 9.16% of air knife soil, 6.68% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com