Water treatment method and device of directional self-repairing flat-plate ceramic membrane assembly

A treatment device and ceramic membrane technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of soft colloidal substances that cannot be removed, low system operating efficiency, and high operating costs , to achieve the effect of improving reliability and efficiency, reducing the number of backwashing times and increasing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

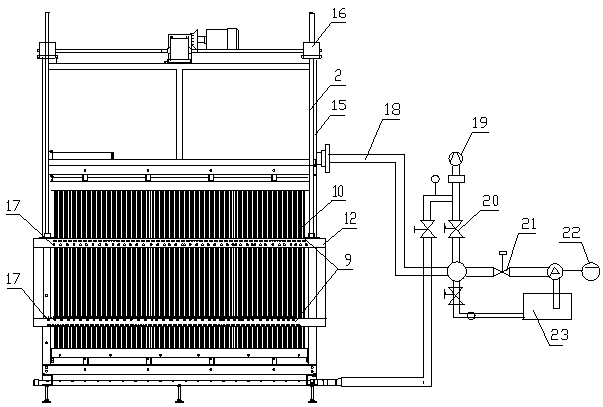

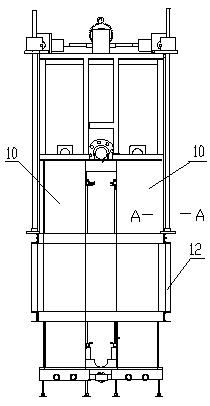

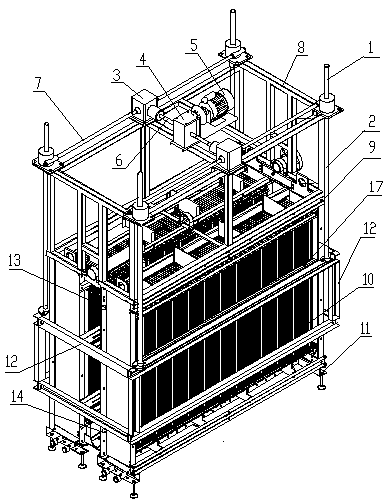

[0027] exist figure 1 , figure 2 , image 3 and Figure 4Among them, the processing device of the directional self-repairing flat ceramic membrane module includes a module frame, a flat membrane module 11 and a filter backwashing device, and the module frame is a rigid structure for fixing the flat membrane module and the aeration mechanism, The flat membrane module includes flat diaphragms 10 arranged at intervals (including flat diaphragms such as organic and inorganic ceramics), an upper plug and a lower plug integrated with the flat diaphragm, and a support frame 8 is arranged on the upper part of the module frame. The support frame is installed above the flat membrane module 11, and the support frame is provided with a lifting mechanism 1, and the lifting mechanism is equipped with a turbine screw 2 respectively, and the rotation of the lifting mechanism drives the turbine screw 2 to move up and down, and a gear conversion is provided in the middle 3, a motor 5 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com