Halogen-free synergistic flame-retardant PBT material with high glow wire, and preparation method thereof

A synergistic flame-retardant and high-glow wire technology, applied in the field of polymer material modification, can solve the problems of high cost of organic hypophosphite, low product cost performance, poor compounding effect, etc., and achieve mechanical performance maintenance, physical mechanics Excellent performance and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

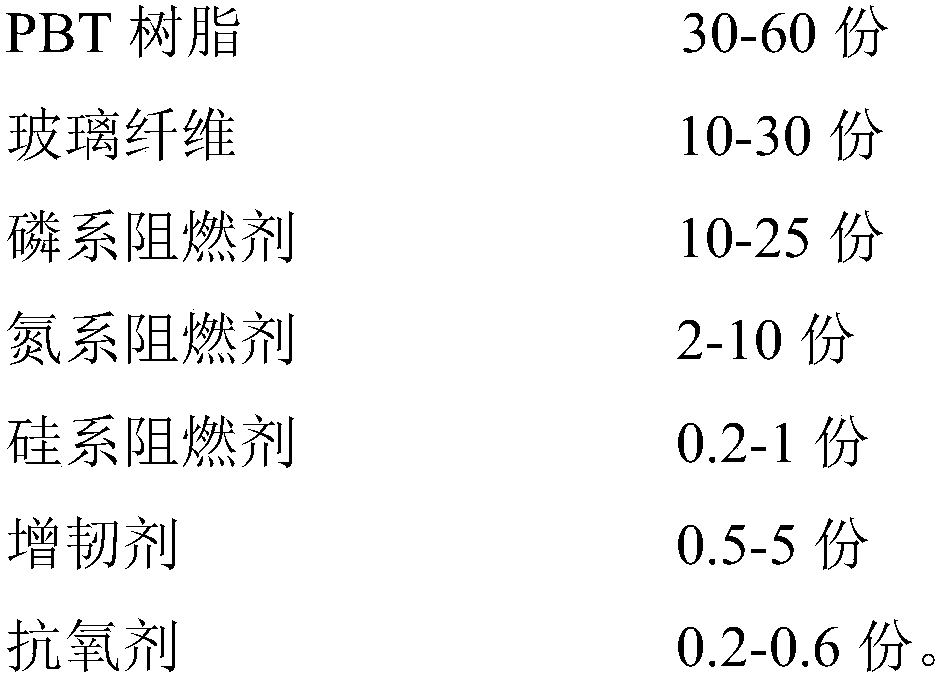

[0034] In this embodiment, the halogen-free synergistic flame-retardant PBT material is composed of the following raw materials in parts by weight:

[0035]

[0036] The PBT resin is polybutylene terephthalate, and its intrinsic viscosity is 1.0dL / g; the glass fiber is an alkali-free glass fiber whose surface has been treated with a silane coupling agent, and the diameter of the glass fiber is 10 μm.

[0037] In this example, the phosphorus-based flame retardant is a mixture of solid phosphate oligomer and melamine polyphosphate, and its weight ratio is 1:1; the nitrogen-based flame retardant uses melamine; the silicon-based flame retardant uses polydimethyl base siloxane.

[0038] The toughening agent is a silicon-acrylic acid copolymer grafted with glycidyl methacrylate, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 at a ratio of 1:1.

[0039] The preparation method of the halogen-free synergistic flame-retardant PBT material in this embodiment...

Embodiment 2

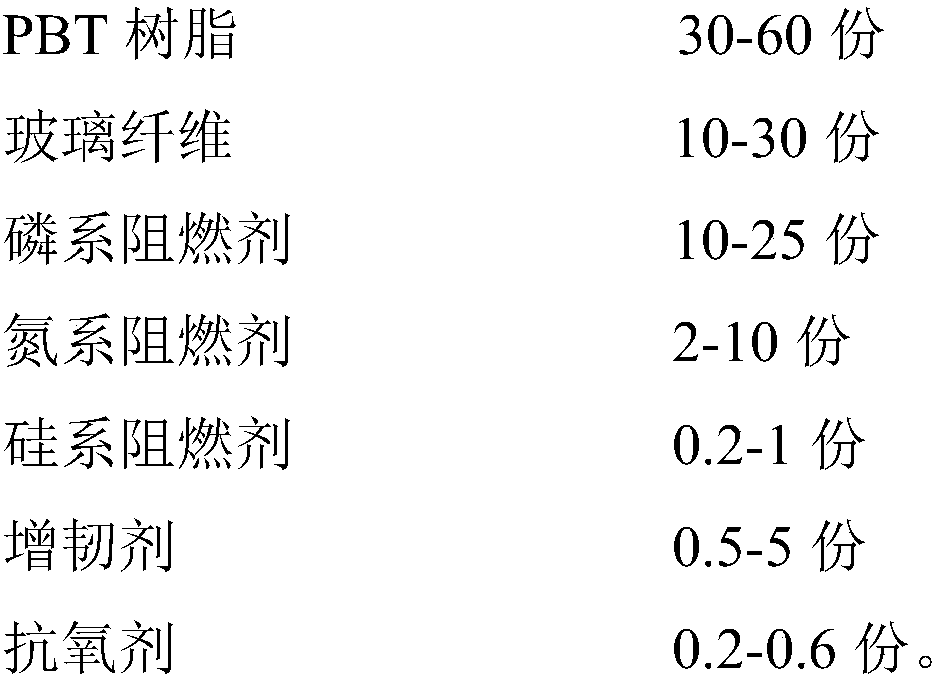

[0045] In this embodiment, the halogen-free synergistic flame-retardant PBT material is composed of the following raw materials in parts by weight:

[0046]

[0047] The PBT resin is polybutylene terephthalate with an intrinsic viscosity of 1.0dL / g; the glass fiber is an alkali-free glass fiber whose surface has been treated with a silane coupling agent.

[0048] In this example, the phosphorus-based flame retardant is a mixture of solid phosphate oligomer and melamine polyphosphate, and its weight ratio is 1:1; the nitrogen-based flame retardant uses melamine cyanurate; the silicon-based flame retardant Using polymethylphenylsiloxane.

[0049] The toughening agent is a silicon-acrylic acid copolymer grafted with glycidyl methacrylate, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 at a ratio of 1:1.

[0050] The preparation method of the halogen-free synergistic flame-retardant PBT material in this embodiment is as follows:

[0051] (1) Put the ...

Embodiment 3

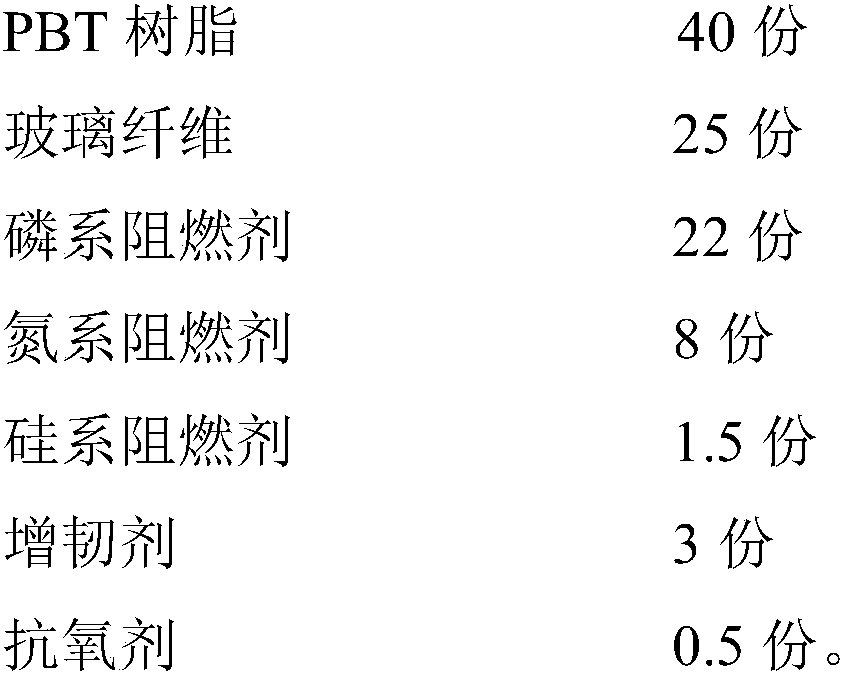

[0056] In this embodiment, the halogen-free synergistic flame-retardant PBT material is composed of the following raw materials in parts by weight:

[0057]

[0058] The PBT resin is polybutylene terephthalate with an intrinsic viscosity of 1.0dL / g; the glass fiber is an alkali-free glass fiber whose surface has been treated with a silane coupling agent.

[0059] In this example, the phosphorus-based flame retardant is a mixture of solid phosphate oligomer and melamine polyphosphate, and its weight ratio is 1:1; the nitrogen-based flame retardant uses polysilsesquioxane; the silicon-based flame retardant The agent adopts polymethylphenylsiloxane.

[0060] The toughening agent is a silicon-acrylic acid copolymer grafted with glycidyl methacrylate, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 at a ratio of 1:1.

[0061] The preparation method of the halogen-free synergistic flame-retardant PBT material in this embodiment is as follows:

[0062] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com