Preparation method of efficient vanadium molybdenum bismuth photoanode with reducing-state surface

A technology of bismuth vanadium molybdate and photoanode, which is applied in electrodes, liquid chemical plating, electrolytic inorganic material coating, etc., can solve the problems of increasing the preparation price and complexity, achieve strong practical value, reduce the preparation cost, and have a reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

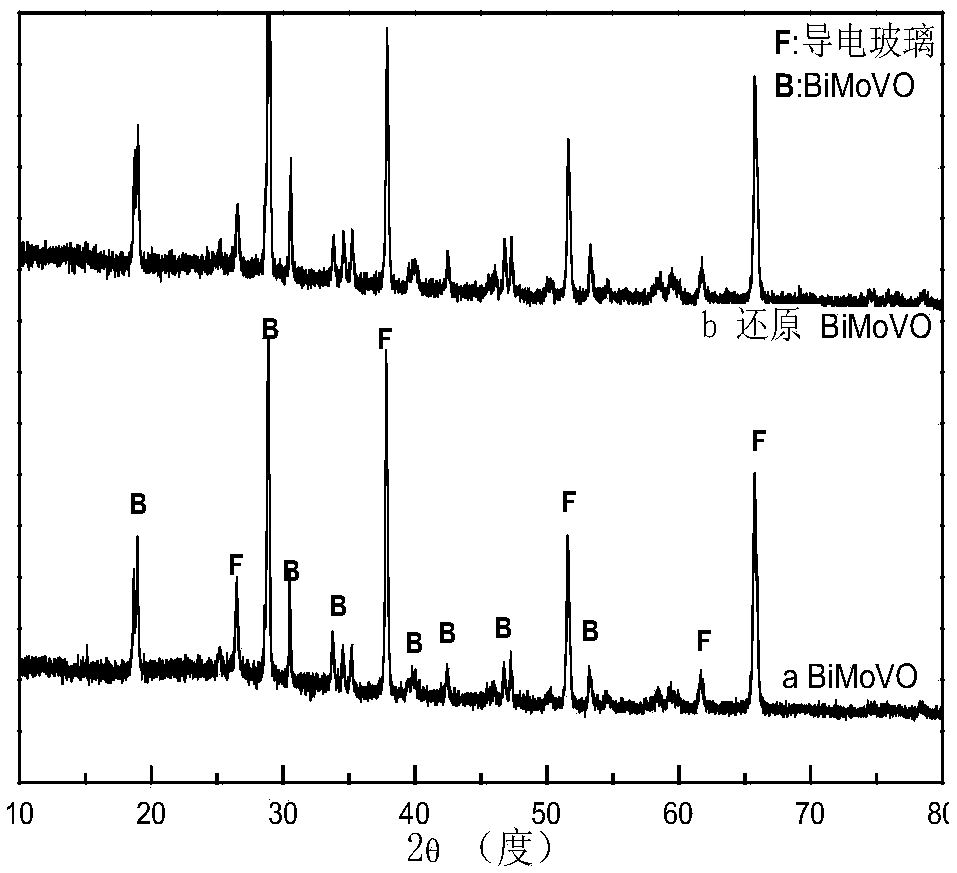

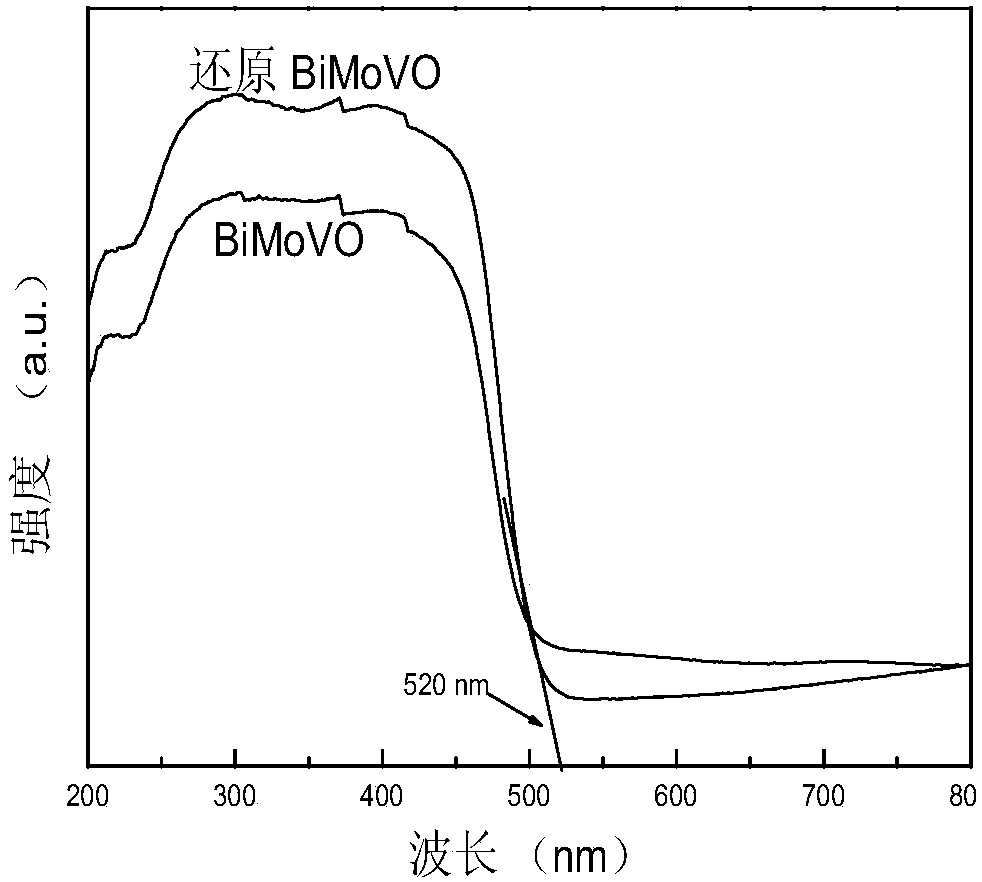

[0032] refer to Figure 1-6 , a method for preparing a high-efficiency bismuth vanadium molybdate photoanode in a reduced surface state, comprising the following steps:

[0033] S1: Prepare raw materials and equipment: Bi(NO 3 ) 3 ·5H 2 O, KI solution, dilute HNO 3 , p-p-benzoquinone, absolute ethanol, vanadium acetylacetonate, dimethyl sulfoxide, molybdenum acetylacetonate solution, muffle furnace and NaOH solution;

[0034] S2: Take 2mmol of Bi(NO 3 ) 3 ·5H 2 O was stirred and mixed in 50 mL of KI solution with a concentration of 2 mol / L, and after being fully dissolved, dilute HNO was added to the obtained solution 3 Adjust the pH to acidic;

[0035] S3: Take 9 mmol of p-p-benzoquinone in S1 and dissolve it ultrasonically in 20 mL of absolute ethanol, mix the obtained solution with the solution prepared in S2, and stir until they are evenly mixed;

[0036] S4: Electrodeposit the solution obtained by mixing in S3 using a three-electrode system and a multi-potential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com