Method for improving mechanical performance of flexible device through graphene oxide self-assembled composite silver nano wire

A silver nanowire, flexible device technology, applied in electrical components, metal/alloy conductors, cable/conductor manufacturing, etc., can solve problems such as affecting the coating effect, achieve strong flexibility and mechanical stability, overall simple operation, and electrical conductivity good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

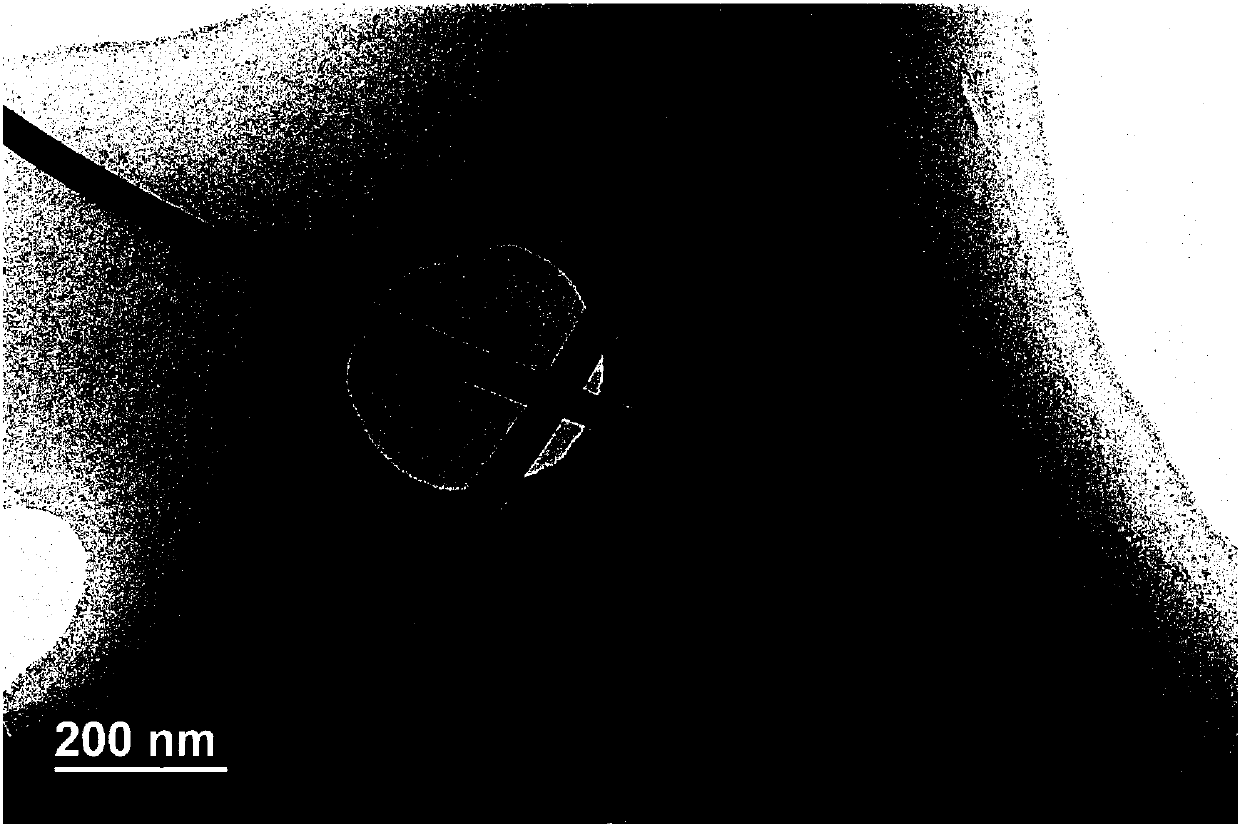

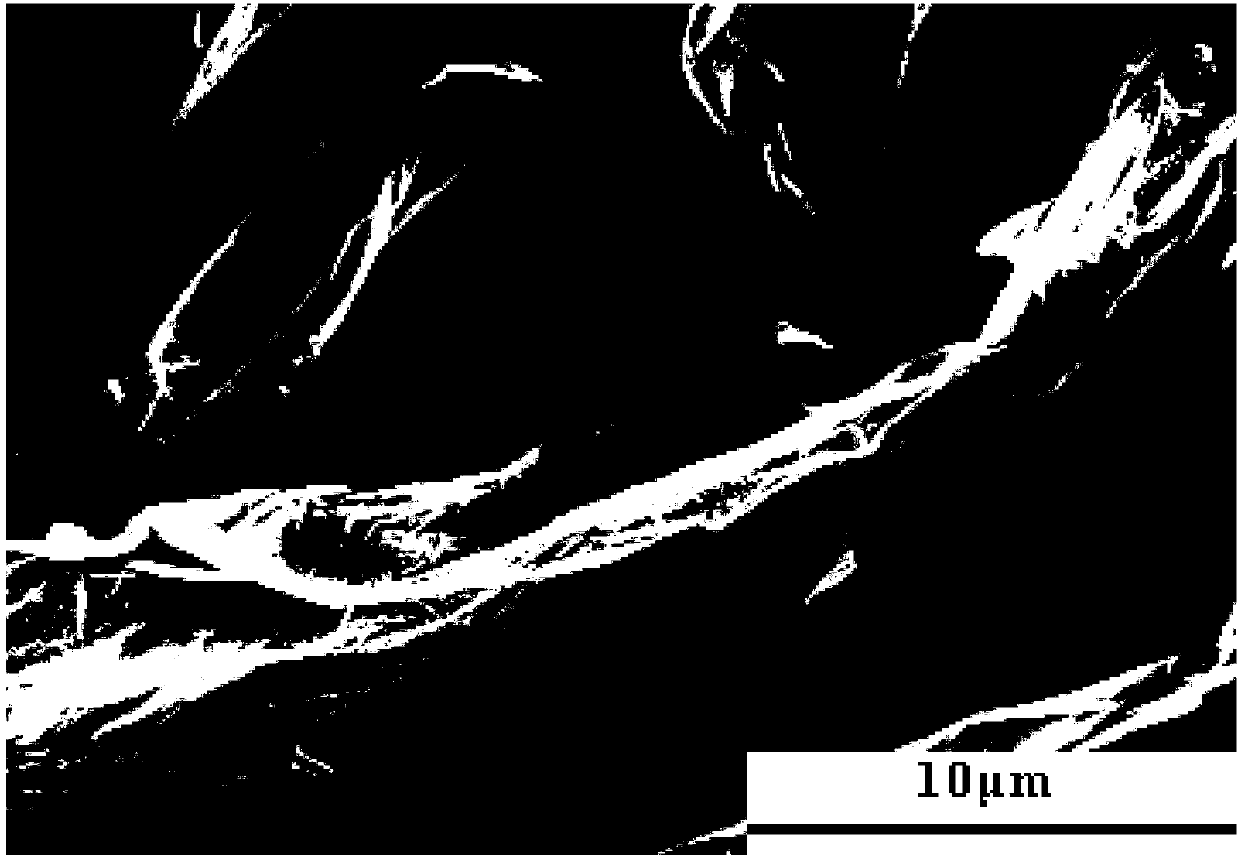

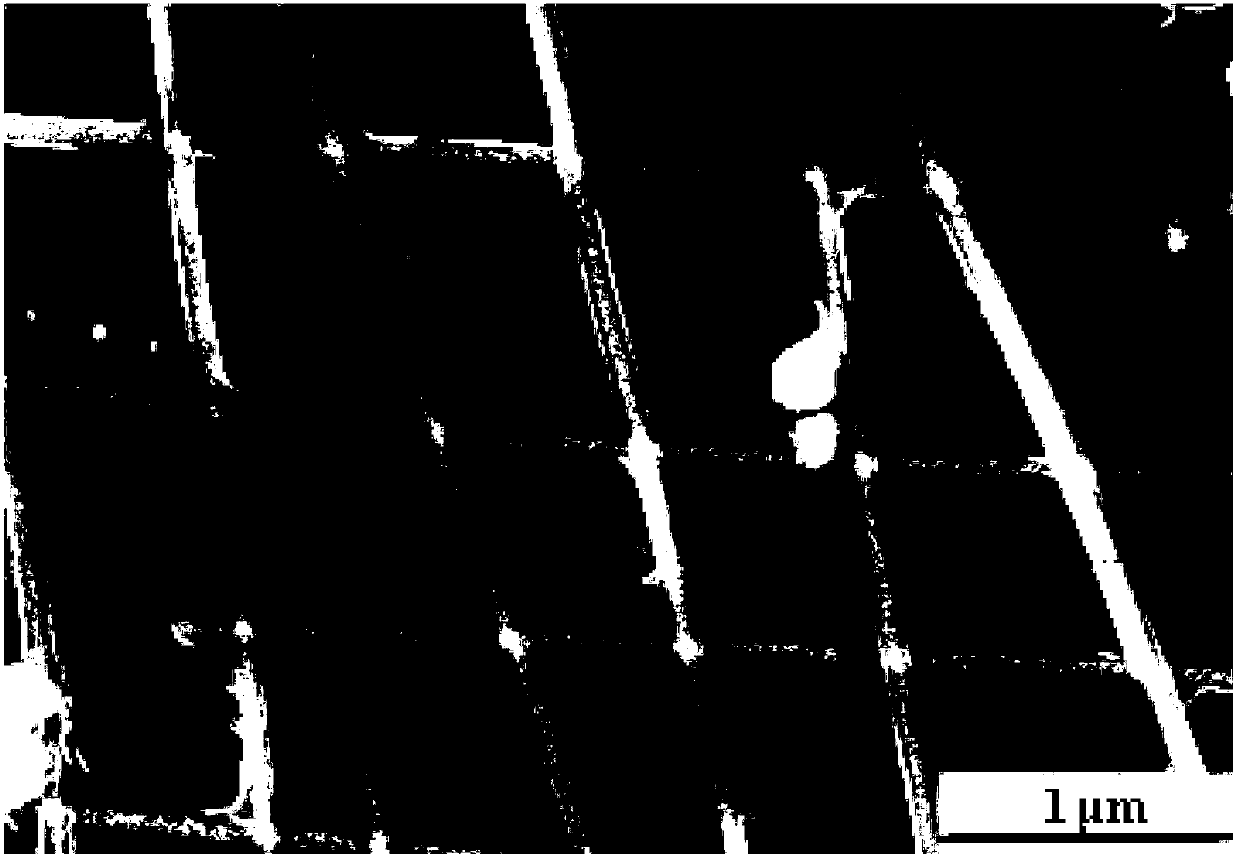

[0053] refer to figure 1 , 2 , 3, and 4: A method for improving the mechanical properties of flexible devices with graphene oxide self-assembled composite silver nanowires, the process flow comprising:

[0054] (1) Silver nanowires were prepared by the polyol reduction method, and the diameter of the prepared silver nanowires was 90 nm and the length was 50 μM;

[0055] (2) Preserve the silver nanowires (Ag NWs) after centrifugal cleaning with ethanol, the concentration is 20mg / ml;

[0056] (3) disperse the dry graphene oxide in deionized water, be mixed with aqueous solution, the volume of deionized water is 100ml;

[0057] (4) After ultrasonic dispersion for 60 minutes, centrifuge at a speed of 4000 r.p.m in a TDL-5-A centrifuge for 30 minutes to remove large precipitates;

[0058] (5) Take the supernatant and continue to centrifuge at 4000r.p.m for 30 minutes to remove small impurities;

[0059] (6) After (5) is processed, the obtained precipitate is redispersed in deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com