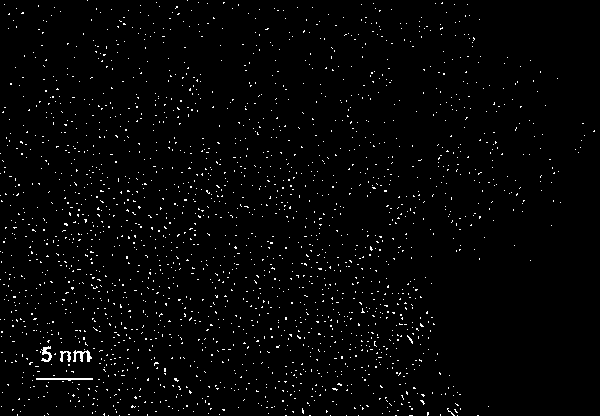

Preparation method of hierarchical pore nitrogen-oxygen-doped carbon super capacitor electrode material

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of difficult structure regulation, difficult removal of template agents, complex synthesis process, etc., and achieves increased conductivity, simple, non-toxic and pollution-free cost. , the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Put 18 g of biomass carbon source egg yolk in a reaction vessel and let it stand at room temperature for 12 hours to obtain material A1;

[0035] (2) Transfer material A1 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen, heat up from room temperature to 300°C for 60 minutes and keep it for 60 minutes, then heat up to 600°C at a heating rate of 5°C / min for carbonization treatment 2h, then naturally cooled to room temperature to obtain material B1;

[0036] (3) Mix 0.5g of material B1 and KOH solid in a reaction vessel at a ratio of 1:4 by mass, then add 5mL of deionized water and fully stir and mix evenly. After standing at room temperature for 12 hours, dry to obtain material C1;

[0037] (4) Transfer material C1 to a nickel boat and place it in a tube furnace. Under the protection of nitrogen, heat up from room temperature to 700 °C for 2 hours at a heating rate of 5 °C / min, and then naturally cool down to room temperature to obt...

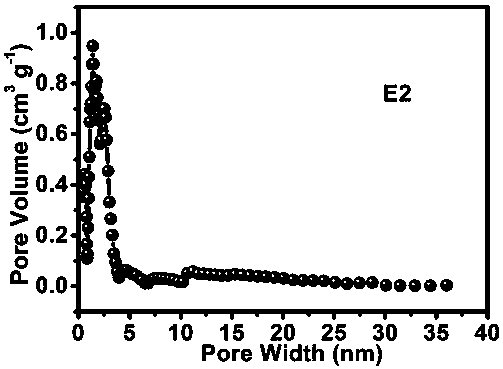

Embodiment 2

[0040] (1) Fully mix 18 g of biomass carbon source egg yolk and 1 g of trisodium thiocyanate in a reaction vessel, and let stand at room temperature for 12 hours to obtain material A2;

[0041](2) Transfer material A2 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen, heat up from room temperature to 300°C for 60 minutes and keep it for 60 minutes, then heat up to 600°C at a heating rate of 5°C / min for carbonization treatment 2h, then naturally cooled to room temperature to obtain material B2;

[0042] (3) Mix 0.5g of material B2 and KOH solid in a reaction vessel at a mass ratio of 1:4, then add 5mL of deionized water and fully stir and mix evenly, let stand at room temperature for 12 hours and then dry to obtain material C2;

[0043] (4) Transfer material C2 to a nickel boat and place it in a tube furnace. Under the protection of nitrogen, heat up from room temperature to 700 °C for 2 hours at a heating rate of 5 °C / min, and then naturally ...

Embodiment 3

[0046] (1) Fully mix 18g of egg yolk as a biomass carbon source and 2g of trisodium thiocyanate in a reaction vessel, and let stand at room temperature for 12 hours to obtain material A3;

[0047] (2) Transfer material A3 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen, heat up from room temperature to 300°C for 60 minutes and keep it for 60 minutes, then heat up to 600°C at a heating rate of 5°C / min for carbonization treatment 2h, then naturally cooled to room temperature to obtain material B3;

[0048] (3) Mix 0.5g of material B3 and KOH solid in a reaction vessel at a mass ratio of 1:4, then add 5mL of deionized water and stir well to mix evenly, let stand at room temperature for 12 hours and then dry to obtain material C3;

[0049] (4) Transfer material C3 to a nickel boat and place it in a tube furnace. Under the protection of nitrogen, heat up from room temperature to 700 °C for 2 hours at a heating rate of 5 °C / min, and then naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com