Fiber-reinforced copper graphite heat dissipation film and preparation method

A graphite heat dissipation film and fiber-reinforced technology, which is applied in chemical instruments and methods, cooling/ventilation/heating modification, modification through conduction and heat transfer, etc., can solve the problem of high equipment process operation requirements, unsuitable promotion, poor mechanical properties, etc. problem, to achieve the effect of improving thermal conductivity, strong machinability, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

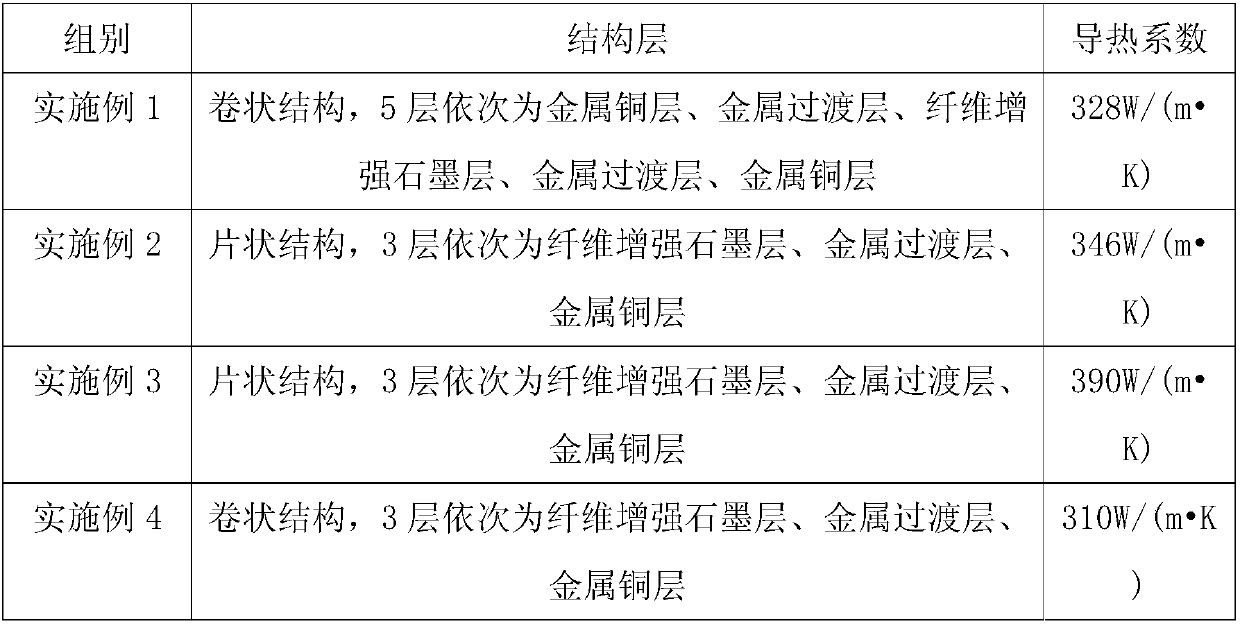

Embodiment 1

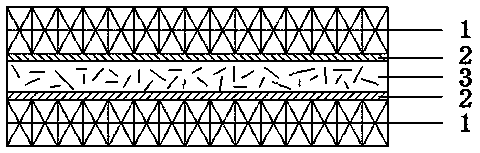

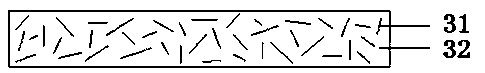

[0043] The fiber-reinforced copper-graphite heat dissipation film includes a fiber-reinforced graphite layer, a metal transition layer and a metal copper layer, wherein the fiber-reinforced graphite layer is: carbon fiber and natural graphite substrate are mixed uniformly according to the mass ratio of 10:90, and the temperature is 1100 ° C Rolling is carried out below, and the rolled carbon fiber reinforced graphite layer that obtains; Described fiber is that carbon fiber length is 5mm; Metal transition layer is nickel metal, and single-layer thickness is 0.1 μ m; The thickness of the layer was 50 μm.

[0044] The preparation method is:

[0045] S1. Dry the fiber-reinforced graphite layer at a temperature of 60°C for 24 hours, and then perform surface treatment on both sides for 2 minutes;

[0046] S2. Using a physical vapor deposition method, the fiber-reinforced graphite layer treated in step S1 is double-sided coated with metal transition layer metal nickel;

[0047] S3....

Embodiment 2

[0049] The fiber-reinforced copper-graphite heat dissipation film includes a fiber-reinforced graphite layer, a metal transition layer and a metal copper layer, wherein the fiber-reinforced graphite layer is: graphite fibers and synthetic graphite substrates are mixed uniformly according to the mass ratio of 30:70, and at a temperature of 1000 Rolling under ℃, the obtained flaky carbon fiber reinforced graphite layer; the fiber is a graphite fiber with a length of 20mm; the metal transition layer is a combination of silver and copper metal, and the single-layer thickness is 0.5 μm; the single-layer thickness of the metal copper layer is 0.5 μm. is 4 μm; the thickness of the fiber reinforced graphite layer is 100 μm.

[0050] The preparation method is:

[0051] S1. Dry the fiber-reinforced graphite layer at a temperature of 80°C for 36 hours, and then perform plasma surface treatment on one side for 5 minutes;

[0052] S2. Using a vacuum evaporation method, one side of the fib...

Embodiment 3

[0055] The fiber-reinforced copper-graphite heat dissipation film includes a fiber-reinforced graphite layer, a metal transition layer and a metal copper layer, wherein the fiber-reinforced graphite layer is: carbon fiber and natural graphite substrate are mixed uniformly according to the mass ratio of 40:60, and the temperature is 900 ° C The carbon fiber reinforced graphite layer obtained by rolling is obtained; the fiber is a carbon fiber with a length of 10 mm; the metal transition layer is aluminum, and the single layer thickness is 0.3 μm; the single layer thickness of the metal copper layer is 10 μm; the fiber reinforced graphite The thickness of the layer is 200 μm.

[0056] The preparation method is:

[0057] S1. Dry the fiber-reinforced graphite layer at a temperature of 100°C for 36 hours, and then perform plasma surface treatment on one side for 10 minutes;

[0058] S2. Using a vacuum evaporation method, one side of the fiber-reinforced graphite layer treated in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com