Rapid inspection method for grease plasticizer

An inspection method and technology of plasticizer, applied in the field of food chemistry, can solve the problems of operator and environmental damage, low recovery rate of plasticizer detection, incomplete extraction of oil, etc., to reduce sample pollution, suitable for process monitoring and batch production. Test and reduce the effect of harm to human body and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of fast inspection method of grease plasticizer, specifically comprises the following steps:

[0038] Step (1): Accurately weigh 1.0±0.1g of oil and place it in a 100mL volumetric flask;

[0039] Step (2): Using the extraction method of soaking in methanol, add 50 mL of methanol into the volumetric flask to obtain a mixed liquid;

[0040] Step (3): Put the mixed liquid obtained in step (2) into an ultrasonic cleaner for 30 minutes, and the ultrasonic power is 300-400W;

[0041] Step (4): Cool the ultrasonicated liquid in step (3) to room temperature, dilute to 100mL, and mix well;

[0042] Step (5): Take 10 mL of the liquid mixed in step (4) and place it in a centrifuge tube for high-speed refrigerated centrifugation; use high-speed refrigerated centrifugation to separate the grease particles contained in methanol, the speed is 5000r / min, the time is 10min, and the temperature is -16 ℃;

[0043] Step (6): The supernatant obtained in step (5) was transferred in...

Embodiment 2

[0060] The test data analysis of embodiment 1

[0061] 1. Reproducibility: Through multiple parallel tests, the reproducibility of the test results is good, and the results are shown in Table 2.

[0062] Table 2 The present invention detects the plasticizer content in different oils

[0063]

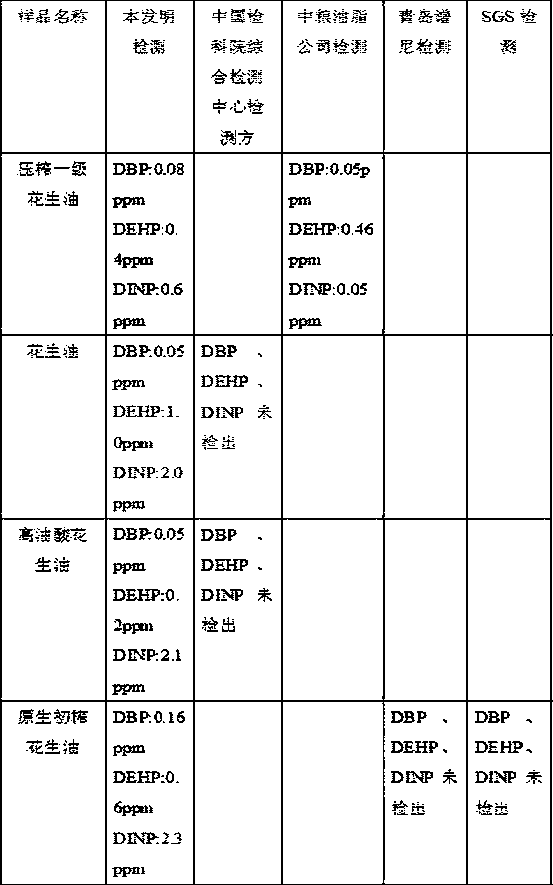

[0064] 2. Accuracy: By comparing with the test results of third-party testing institutions (Chinese Academy of Sciences, Pony, SGS) and COFCO, the results of samples treated with this pre-treatment method are compared in Table 3.

[0065] Table 3 The present invention compares with different detection method detection results

[0066]

[0067] Note: Not detected means that the item is less than the detection limit (DBP<0.3ppm, DEHP<1.5ppm, DINP<9.0ppm).

[0068] Conclusion: Through multiple parallel tests and standard addition tests, it is shown that the method has strong repeatability. The content of plasticizer is in the range of 0.01mg / kg-0.2mg / kg, and the absolute value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com