Molybdenum telluride positive electrode material for lithium-ion battery and preparation method of molybdenum telluride positive electrode material

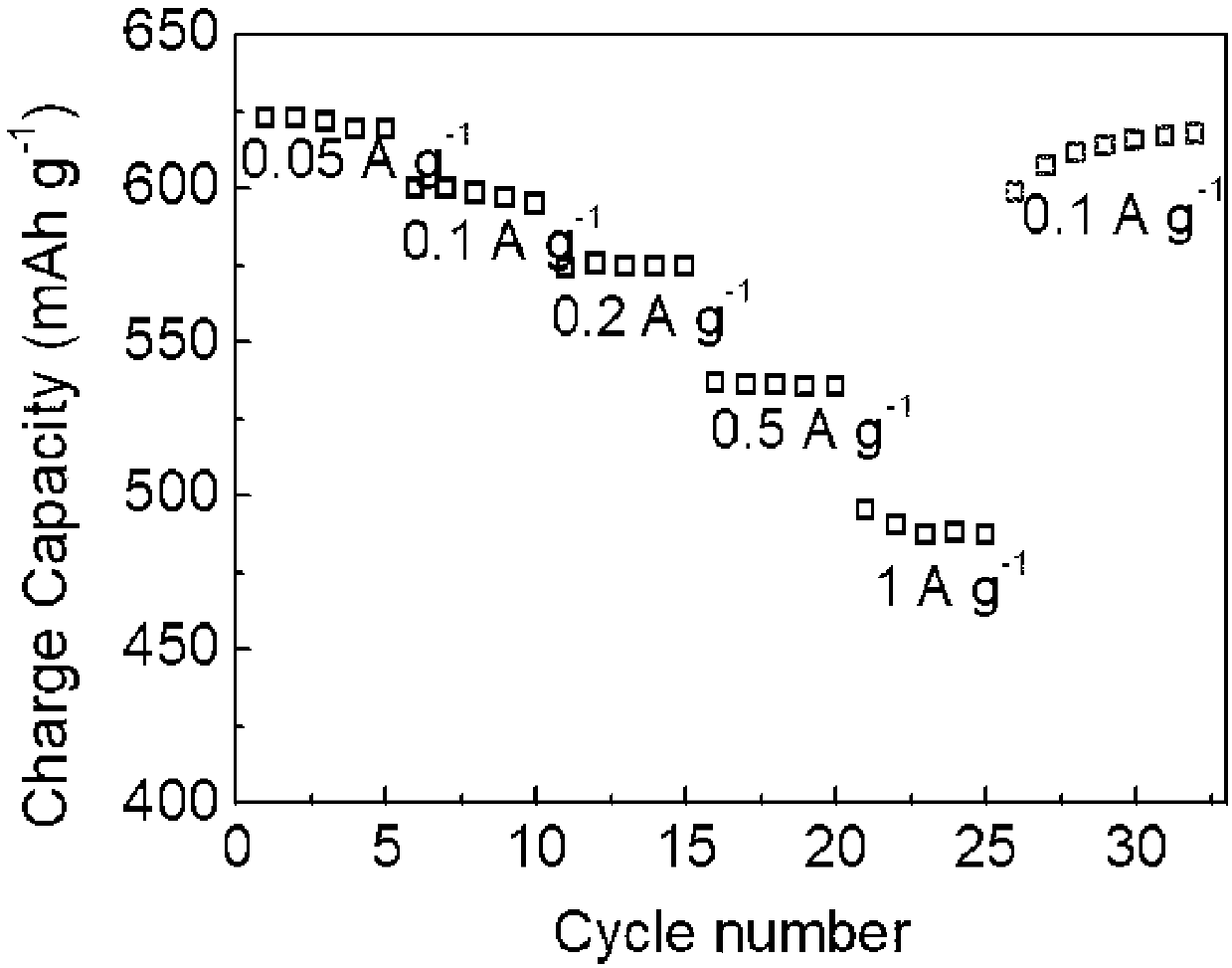

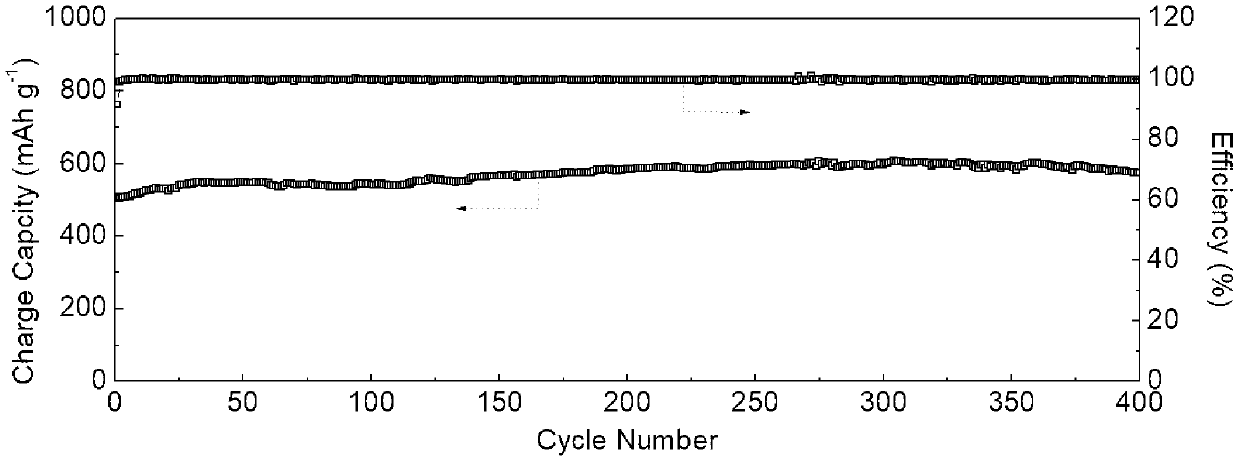

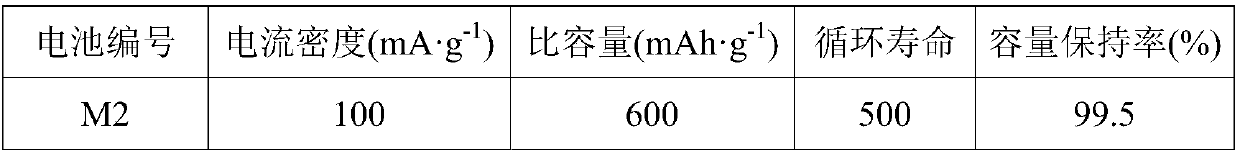

A lithium ion battery and anode material technology, which is applied in the field of lithium ion battery molybdenum telluride anode materials and their preparation, and can solve the problems of poor cycle performance, poor rate performance of anode materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] This embodiment also provides a method for preparing a molybdenum telluride anode material for a lithium-ion battery. molybdenum anode material.

[0016] Specifically, it also includes the step of preparing 1T' type molybdenum ditelluride crystal:

[0017] 1) Mix molybdenum powder and tellurium powder according to the molar ratio of 1:2, and fire at 800-1000°C for 72-168 hours under vacuum to obtain molybdenum ditelluride polycrystalline powder;

[0018] 2) Mixing the polycrystalline molybdenum ditelluride powder and tellurium tetrachloride at 800-1000°C, firing for 72-168 hours, and then recrystallizing by chemical vapor phase transfer to obtain molybdenum ditelluride crystals;

[0019] 3) Quenching the molybdenum ditelluride crystal in cold water to obtain 1T' type molybdenum ditelluride crystal.

[0020] Specifically, the rotation speed in the ball mill is 300-600 rpm, and the time is 12-48 hours.

[0021] Specifically, the mass concentration of tellurium tetrachl...

Embodiment 1

[0027] This implementation provides a molybdenum telluride anode material for a lithium ion battery, which includes a 1T' type molybdenum ditelluride crystal and graphene coated on the outer surface of the 1T' type molybdenum ditelluride crystal, and the graphene is The mass ratio in the molybdenum anode material is 10%. This embodiment also provides a method for preparing a molybdenum telluride anode material for a lithium ion battery, specifically as follows:

[0028] 1) Mix molybdenum powder and tellurium powder into the silicon ampoule at a molar ratio of 1:2, seal the silicon ampoule with a rotary vacuum sealing system, and heat to 800°C for 72 hours to obtain molybdenum ditelluride polycrystalline powder ;

[0029] 2) The molybdenum ditelluride polycrystalline powder and mass concentration obtained in step 1) are 2.7mg.ml -1 Add tellurium tetrachloride into a silicon ampoule and mix, heat to 900°C and burn for 100 hours, then recrystallize by chemical vapor phase trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com