Preparation method of medicinal auxiliary material

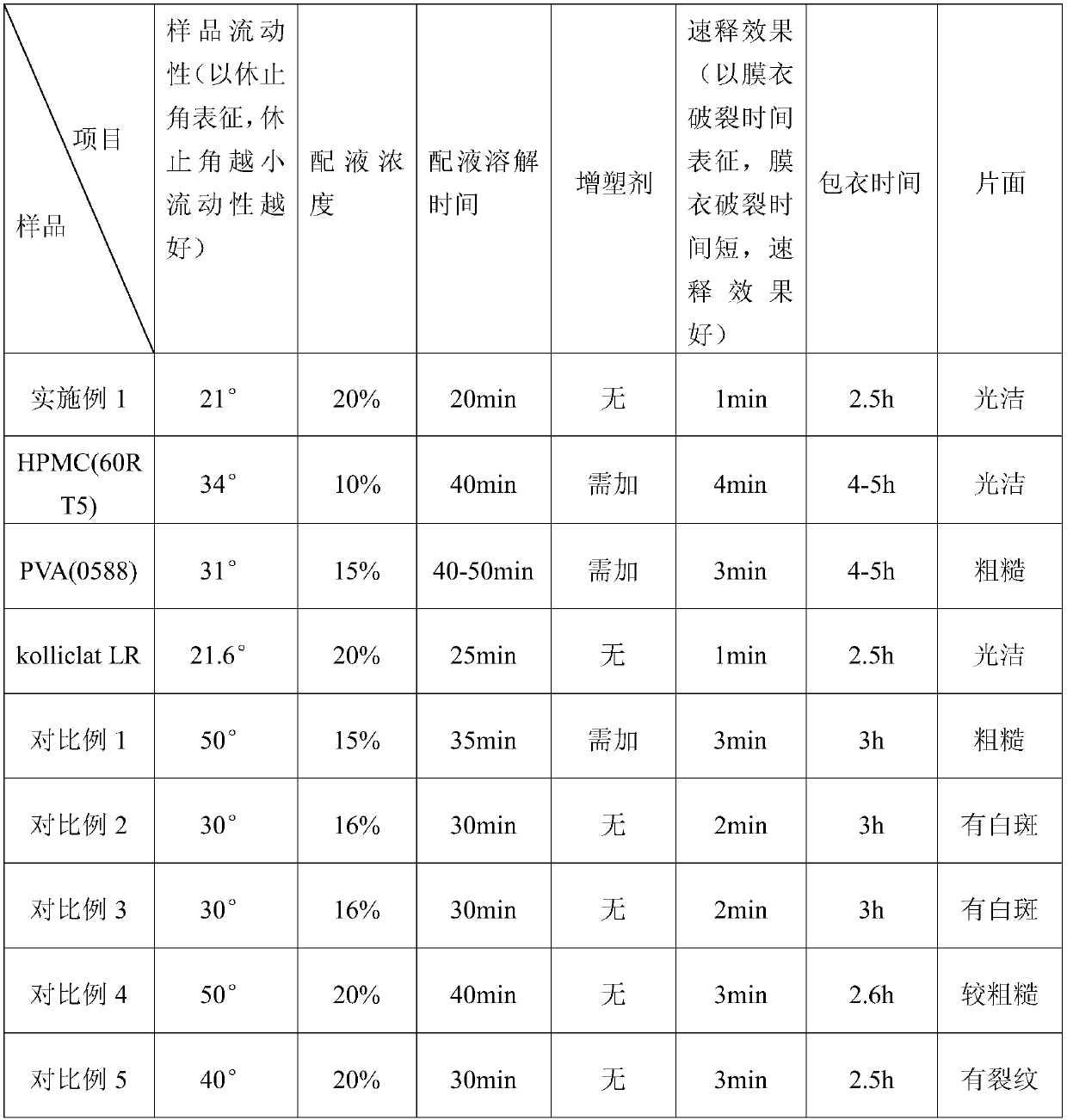

A technology of pharmaceutical excipients and polyvinyl alcohol, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, sugar-coated pills, etc. In order to solve the problems of poor performance and other problems, the formula is simple and easy to implement, the types of raw materials are few, and the coating effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of pharmaceutical excipients, comprising the steps of:

[0027] Add 2 tons of medical deionized water to the kettle, heat up to 90°C, add 375kg of PVA (0588), the weight average molecular weight is 27000, the viscosity of 10wt% polyvinyl alcohol aqueous solution at 20°C is 5mpa.s, and the degree of alcoholysis is 88 %, stir for 3-5h until fully dissolved, add 125kg PEG6000, the weight average molecular weight is 6000, stir until fully dissolved, replenish 600kg of water, adjust the pH value to 7 with solid sodium hydroxide, and the mass ratio of PVA to PEG is 3:1.

[0028] In the 300-type centrifugal spray drying tower, the spray drying temperature is 120°C, the air inlet temperature is 140°C, the air outlet temperature is 80°C, the spray drying pressure is -400Pa, and the powdery finished pharmaceutical excipients are dried with a mesh size of 60- 70 mesh.

Embodiment 2

[0030] A preparation method of pharmaceutical excipients, as described in Example 1, the difference is: PEG6000 is replaced by PEG4000 with a weight average molecular weight of 4000, and other steps are consistent with Example 1.

[0031] This embodiment can also obtain qualified finished products, but the powder is easy to agglomerate.

Embodiment 3

[0033] A preparation method of a pharmaceutical excipient, as described in Example 1, the difference is: PVA (0588) is replaced by PVA (1788) with a weight average molecular weight of 84,000, and a viscosity of 10 wt% polyvinyl alcohol aqueous solution at 20°C is 26mpa .s, alcoholysis degree is 88%, other steps are consistent with embodiment 1.

[0034] What the present embodiment obtains is free-flowing powder, obtains qualified product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com