Carbon material-black phosphorene composite aerogel and preparation method thereof

A technology of composite aerogels and carbon materials, applied in the fields of phosphorus compounds, chemical instruments and methods, phosphorus, etc., can solve problems such as limiting the development of black phosphorene materials, achieve excellent photothermal conversion characteristics, ensure integrity, and good electrical conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take 2mg of multi-walled carbon nanotubes with a diameter of about 15nm and a length of about 20μm and 1mg of two-dimensional black phosphorus nanosheets with an average size of 5μm and a thickness of 2nm, mix and disperse them in isopropanol, and then mix the mixture at 1500rpm / min Stir at a speed of 2h, then centrifuge the mixed solution at 10000rpm / min for 3min, ultrasonically disperse the precipitated part in cyclohexane (ultrasonic time is 10min, ultrasonic power 600W), then let it stand for 10min, and then place it at -80°C Freezing for 2 hours, followed by freeze-drying, the freeze-drying temperature is -80°C, the vacuum value is 0.01mbar, and the freeze-drying time is 12 hours, and the multi-walled carbon nanotube-herophosphorene composite airgel can be obtained.

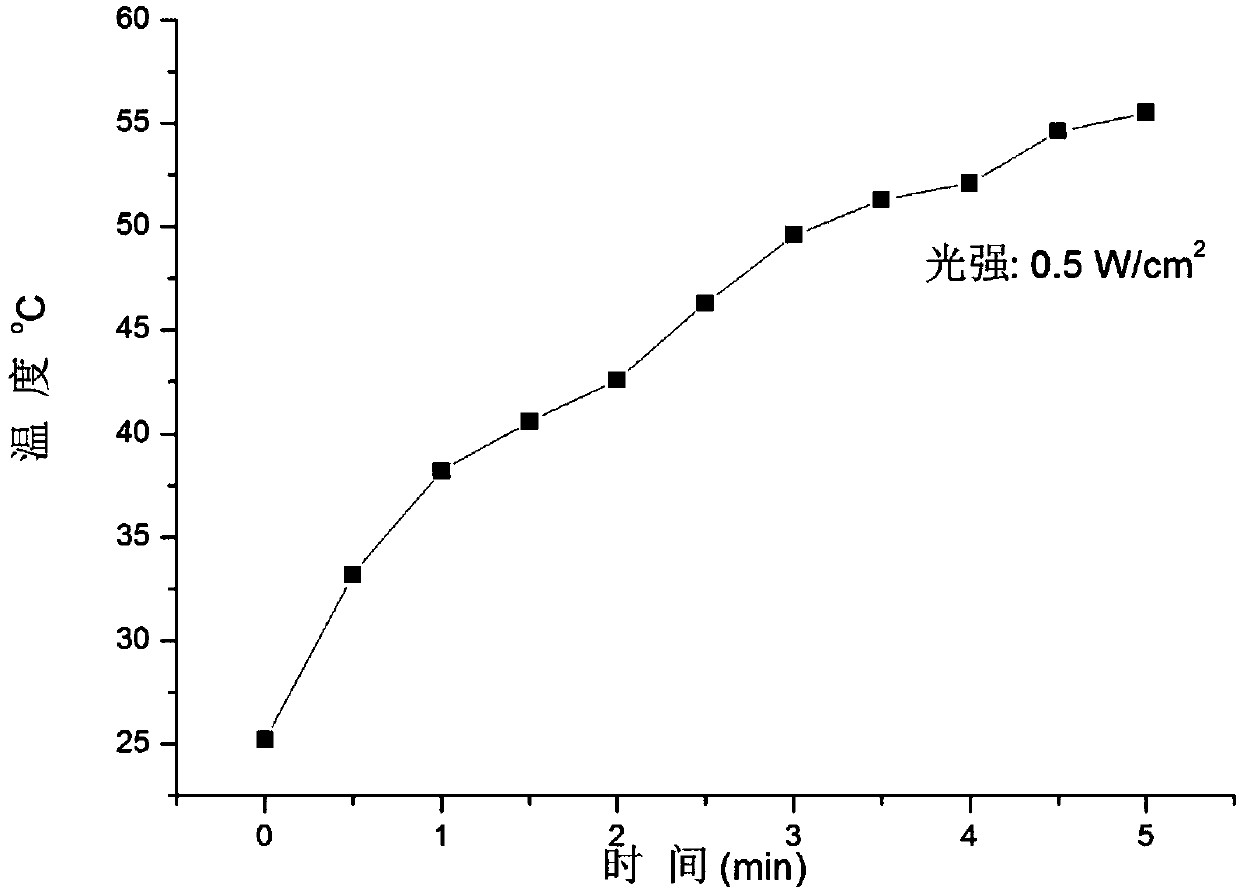

[0049] The photothermal conversion efficiency of the prepared multi-walled carbon nanotubes-black phosphorene composite airgel is 11%, and the density is 5.1mg / cm 3 , with a porosity of 80% and a spec...

Embodiment 2

[0053] Take 1 mg of graphene with an average size of 5 μm and a thickness of about 3 nm and 1 mg of two-dimensional black phosphorus nanosheets with an average size of 2 μm and a thickness of 6 nm, mix and disperse them in isopropanol, and then stir the mixture at a speed of 1000 rpm / min 3h, then centrifuge the mixed solution at 10000rpm / min for 5min, ultrasonically disperse the precipitated part in cyclohexane (ultrasonic time is 8min, ultrasonic power 800W), then let stand for 15min, and then freeze at -70°C for 3h, Then carry out freeze-drying, the freeze-drying temperature is -70 ° C, the vacuum value is 0.1 mbar, and the freeze-drying time is 24 hours, and the graphene-black phosphorene composite airgel can be obtained.

[0054] The photothermal conversion efficiency of the prepared graphene-black phosphorene composite airgel is 14%, and the density is 6.2mg / cm 3 , with a porosity of 75% and a specific surface area of 1000m 2 / g.

[0055] figure 2 For the micrograph...

Embodiment 3

[0057] Take 0.5 mg of single-walled carbon nanotubes with a diameter of about 2 nm and a length of about 5 μm and 1 mg of two-dimensional black phosphorus nanosheets with an average size of 8 μm and a thickness of 3 nm, mix and disperse them in isopropanol, and then mix the mixture at 800 rpm / Min speed stirring for 2h, and then the mixed solution was centrifuged at 10000rpm / min for 6min, and the precipitated part was ultrasonically dispersed in cyclohexane (ultrasonic time was 15min, ultrasonic power 300W), then stood still for 12min, and then placed at -60 ℃ freezing for 5 hours, followed by freeze-drying, the freeze-drying temperature is -60°C, the vacuum value is 1mbar, and the freeze-drying time is 18 hours, and the single-wall carbon nanotube-herophosphorene composite airgel can be obtained.

[0058] The photothermal conversion efficiency of the prepared single-wall carbon nanotube-black phosphorene composite airgel is 18%, and the density is 4.5mg / cm 3 , with a porosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com