Brewer's yeast culture and fermentation technology thereof

A technology of Saccharomyces cerevisiae and fermentation process, which is applied in the field of Saccharomyces cerevisiae culture and its fermentation process, which can solve the problems of no liquid anaerobic fermentation metabolites, insufficient solid fermentation, low yeast activity, etc., and achieve excellent palatability , improve smell, high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

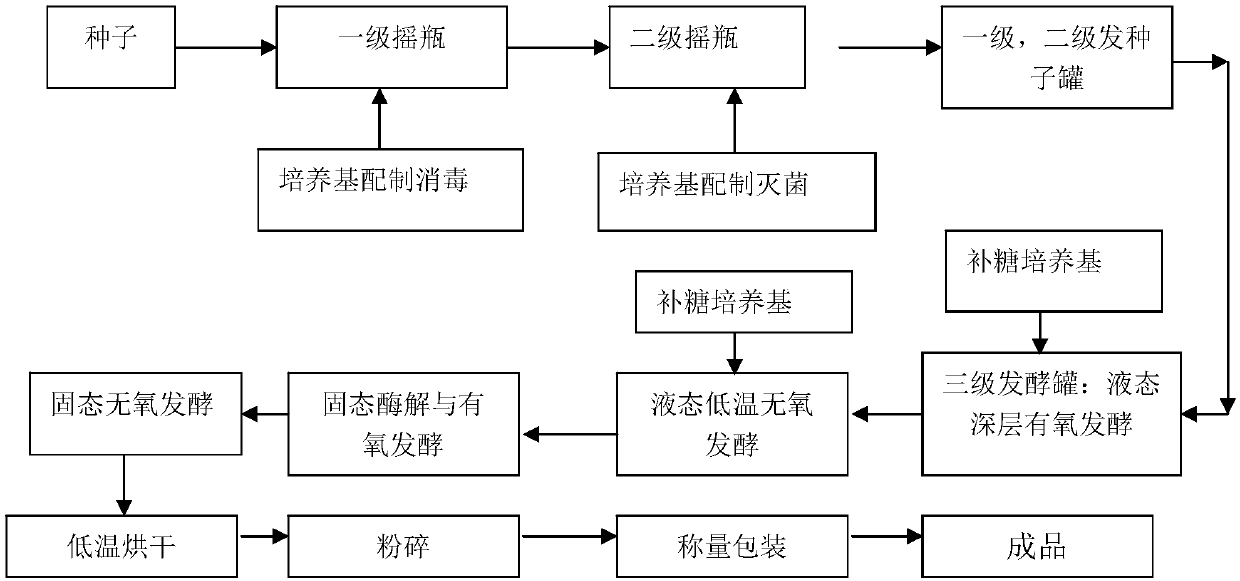

[0049] As an embodiment of the present invention, the fermentation process of the yeast culture comprises the following steps:

[0050] (1) Shake flask seed culture (first-level and second-level seed liquid): take Saccharomyces cerevisiae strain Sa-10 preserved at ultra-low temperature (for example, liquid nitrogen at -196°C) for activation, and then inoculate the activated Saccharomyces cerevisiae 1~2 loops into the primary shake flask culture medium, shake culture at 28~30°C, 180~200rpm for 17~24 hours to obtain the first grade seed liquid, and then inoculate the first grade seed liquid into the secondary shake flask medium, 28° C. to 30° C., 180 to 200 rpm shaker shake culture for 20 to 24 hours to obtain shake flask seed culture solution.

[0051] Wherein, the primary shake flask medium and the secondary shake flask medium are YPD liquid medium, and the composition of the YPD liquid medium is: glucose 20g, tryptone 20g, yeast extract powder 10g, 1000ml water, natural pH; ...

Embodiment 2

[0064] As an embodiment of the present invention, the fermentation process of the yeast culture comprises the following steps:

[0065] (1) Shake flask seed culture (first-level and second-level seed liquid): take Saccharomyces cerevisiae strain Sa-10 preserved at ultra-low temperature (for example, liquid nitrogen at -196°C) for activation, and then inoculate the activated Saccharomyces cerevisiae 1~2 loops into the primary shake flask culture medium, shake culture at 28~30°C, 180~200rpm for 17~24 hours to obtain the first grade seed liquid, and then inoculate the first grade seed liquid into the secondary shake flask medium, 28° C. to 30° C., 180 to 200 rpm shaker shake culture for 20 to 24 hours to obtain shake flask seed culture solution.

[0066] Wherein, the primary shake flask medium and the secondary shake flask medium are YPD liquid medium, and the composition of the YPD liquid medium is: glucose 10g, tryptone 10g, yeast extract powder 5g, 1000ml water, natural pH; T...

Embodiment 3

[0079] As another embodiment of the present invention, the fermentation process of the yeast culture comprises the following steps:

[0080] (1) Shake flask seed culture (first-level and second-level seed liquid): take Saccharomyces cerevisiae strain Sa-10 preserved at ultra-low temperature (for example, liquid nitrogen at -196°C) for activation, and then inoculate the activated Saccharomyces cerevisiae 1~2 loops into the primary shake flask culture medium, shake culture at 28~30°C, 180~200rpm for 17~24 hours to obtain the first grade seed liquid, and then inoculate the first grade seed liquid into the secondary shake flask medium, 28° C. to 30° C., 180 to 200 rpm shaker shake culture for 20 to 24 hours to obtain shake flask seed culture solution.

[0081] Wherein, the primary shake flask medium and the secondary shake flask medium are YPD liquid medium, and the composition of the YPD liquid medium is: glucose 15g, tryptone 30g, yeast extract powder 15g, 1000ml water, natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com