Method for biosynthesis of magnolol

A technology of biosynthesis and synthesis method, applied in fermentation and other directions, can solve the problems of many organic solvents, serious chemical pollution, complicated organic chemical production steps, etc., and achieve the effects of warm reaction conditions, high content, and easy industrial transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

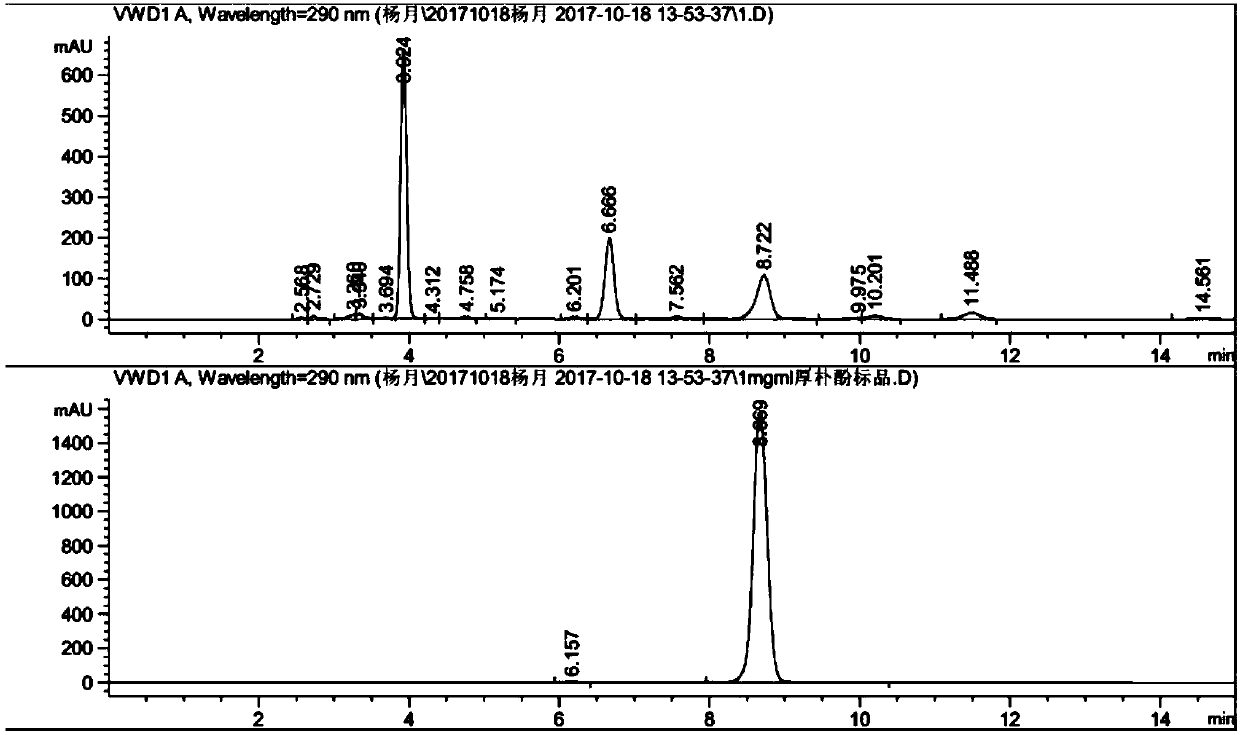

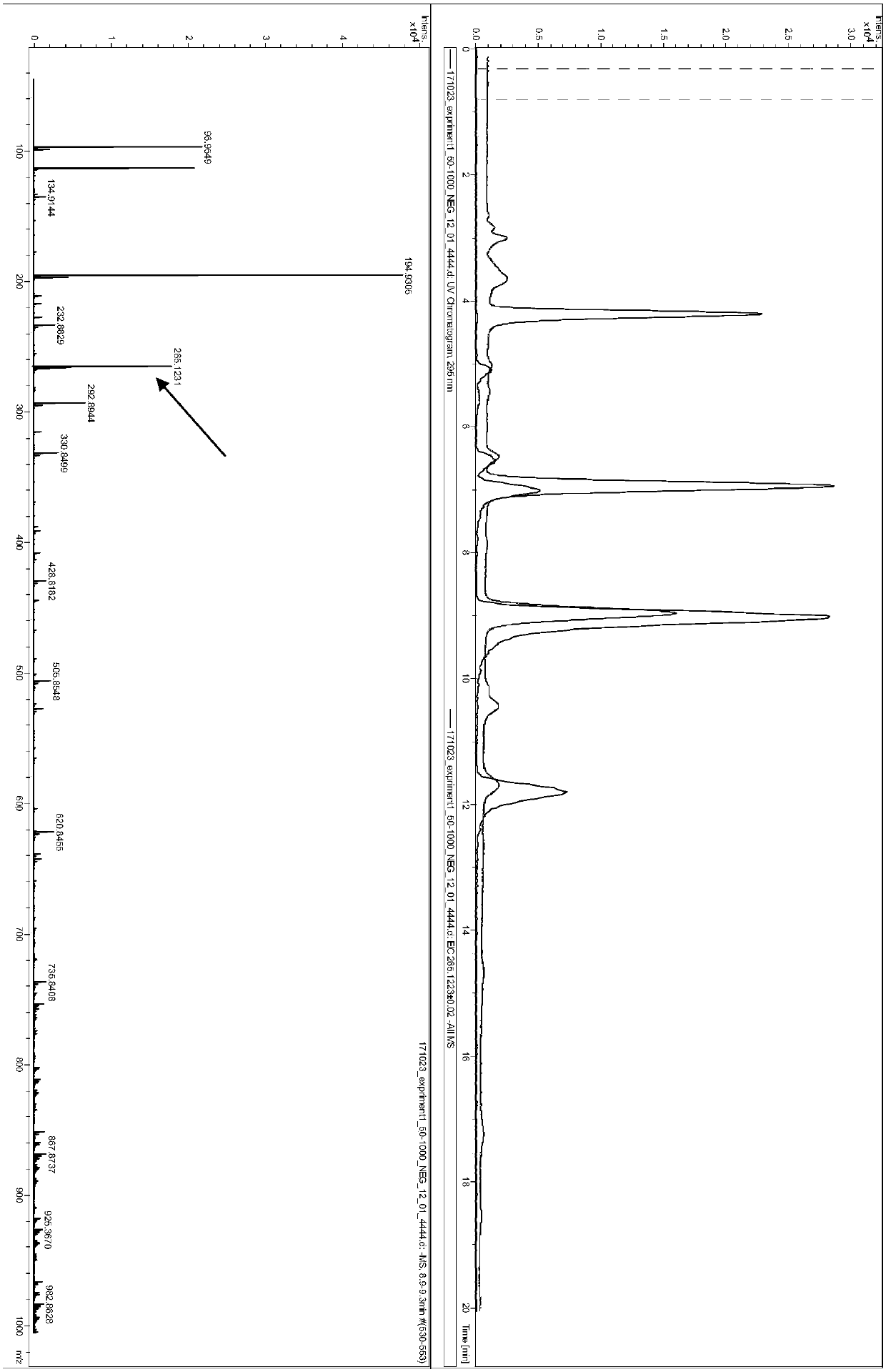

Examples

Embodiment 1

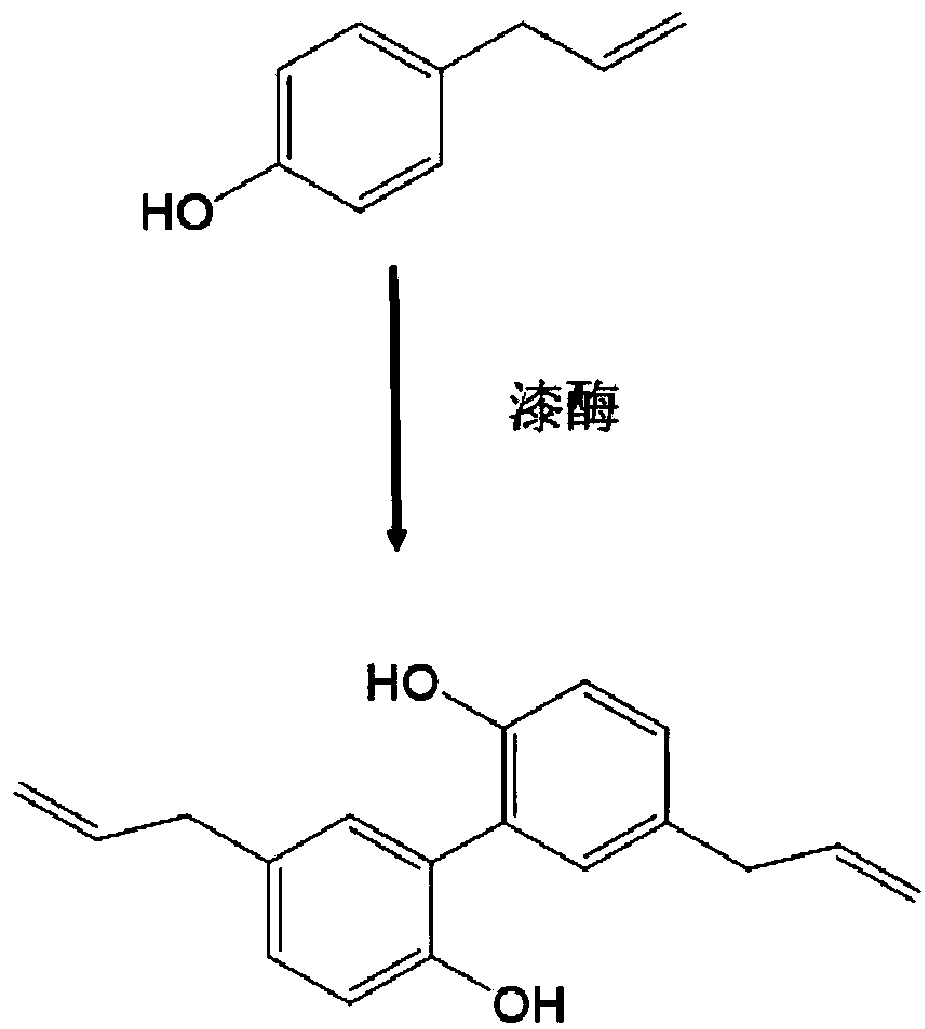

[0033] A method for biosynthesizing magnolol, wherein the synthetic method takes 4-allylphenol as raw material and completes it through the catalysis of laccase, and the method steps are as follows:

[0034] 1) First prepare a 50mM potassium dihydrogen phosphate solution, then use dipotassium hydrogen phosphate to adjust the pH to 6, and filter it for later use;

[0035] 2) Use methanol to configure 50mg / ml 4-allylphenol solution;

[0036] 3) Dissolving laccase in the potassium dihydrogen phosphate solution prepared in step 1), the concentration is 50 mg / ml;

[0037] 4) Configure the reaction system: the volume of the reaction system is 2ml, use the potassium dihydrogen phosphate solution configured in step 1) as a buffer, add the 4-allylphenol solution in step 2) to make the final concentration 4mg / ml , adding the enzyme in step 3) to make the final concentration 1mg / ml;

[0038] 5) The reaction system was placed at 37°C, and the reaction was shaken for 3.5 hours;

[0039]...

Embodiment 2

[0042] A kind of method of biosynthesis magnolol, described synthetic method is with 4-allyl phenol as raw material, finishes through the catalysis of laccase, and described method step is as follows:

[0043] 1) First prepare a 55mM potassium dihydrogen phosphate solution, then use dipotassium hydrogen phosphate to adjust the pH to 6.2, and filter it for later use;

[0044] 2) Use methanol to configure 55mg / ml 4-allylphenol solution;

[0045] 3) Dissolving laccase in the potassium dihydrogen phosphate solution prepared in step 1), the concentration is 55 mg / ml;

[0046] 4) Configure the reaction system: the volume of the reaction system is 3ml, use the potassium dihydrogen phosphate solution configured in step 1) as a buffer, add the 4-allylphenol solution in step 2) to make the final concentration 5mg / ml , adding the enzyme in step 3) to make the final concentration 1.2mg / ml;

[0047] 5) The reaction system was placed at 38°C, and the reaction was shaken for 2 hours;

[0...

Embodiment 3

[0051] A method for biosynthesizing magnolol, wherein the synthetic method takes 4-allylphenol as a raw material and completes it through the catalysis of laccase, and the steps of the method are as follows:

[0052] 1) First prepare a 50mM potassium dihydrogen phosphate solution, then use dipotassium hydrogen phosphate to adjust the pH to 6, and filter it for later use;

[0053] 2) Use methanol to configure 50mg / ml 4-allylphenol solution;

[0054] 3) Dissolving laccase in the potassium dihydrogen phosphate solution prepared in step 1), the concentration is 50 mg / ml;

[0055] 4) Configure the reaction system: the volume of the reaction system is 2ml, use the potassium dihydrogen phosphate solution configured in step 1) as a buffer, add the 4-allylphenol solution in step 2) to make the final concentration 5mg / ml , adding the enzyme in step 3) to make the final concentration 1mg / ml;

[0056] 5) The reaction system was placed at 37°C and shaken for 3 hours;

[0057] 6) centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com