Preparation method of graphene electrothermal materials with controllable electrothermal performance

An electrothermal material and graphene technology, applied in heating element materials, electrothermal devices, ohmic resistance heating, etc., can solve problems such as organic solvent pollution to the environment, and achieve the effect of achieving controllability and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a graphene electrothermal material with controllable electrothermal performance, comprising the steps of:

[0022] Step A, using graphene slurry as a conductive filler, using water-based polyurethane emulsion as a binder, and adding an emulsifier with a mass fraction of 3%, thereby preparing a graphene electric heating carbon slurry.

[0023] Step B, using polyethylene terephthalate PET film as a carrier, setting 2 to 20 wires on the PET film, and the distance between two adjacent wires is 0.1 to 50 cm, and then the graphite The graphene electrothermal carbon paste is coated on the wire and the PET film, and then dried (the drying temperature is preferably 120° C.), so as to obtain a graphene electrothermal material with controllable electrothermal properties.

Embodiment approach

[0025] (1) By applying a safety voltage to wires with different spacings on the graphene electrothermal material with controllable electrothermal performance, the surface temperature of the graphene electrothermal material with controllable electrothermal performance is changed to realize its controllable electrothermal performance. For example: for the graphene electrothermal material with controllable electrothermal properties prepared by graphene electrothermal carbon paste with a graphene slurry content of 80wt%, if three wires are arranged on the PET film, and the distance between two adjacent wires is The distance is 2cm, then when a 3.7v safety voltage is applied to two wires that are 2cm apart, the surface temperature of the graphene electrothermal material with controllable electrothermal performance is 75°C, and when 3.7v is applied to two wires that are 4cm apart At v safe voltage, the surface temperature of the graphene electrothermal material with controllable elec...

Embodiment 1

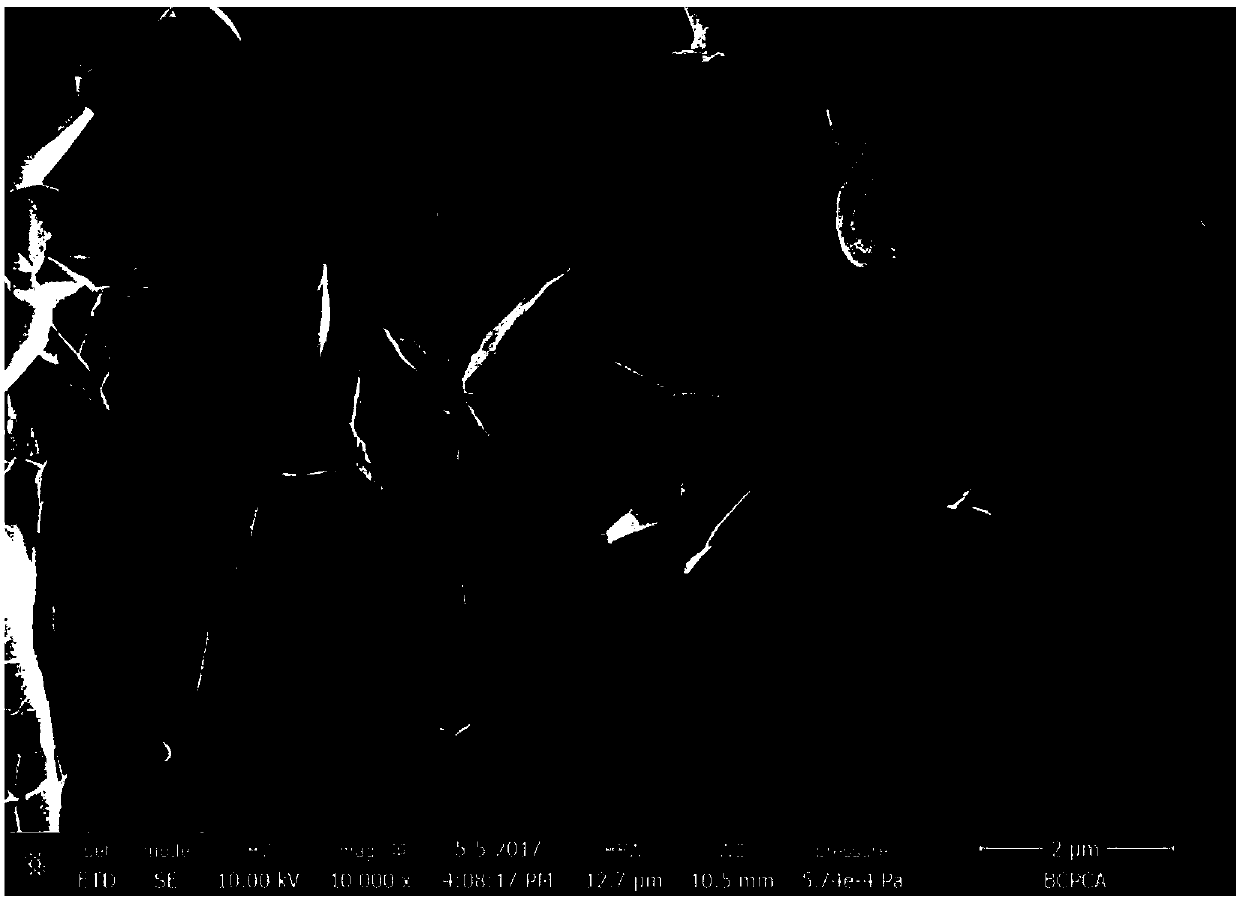

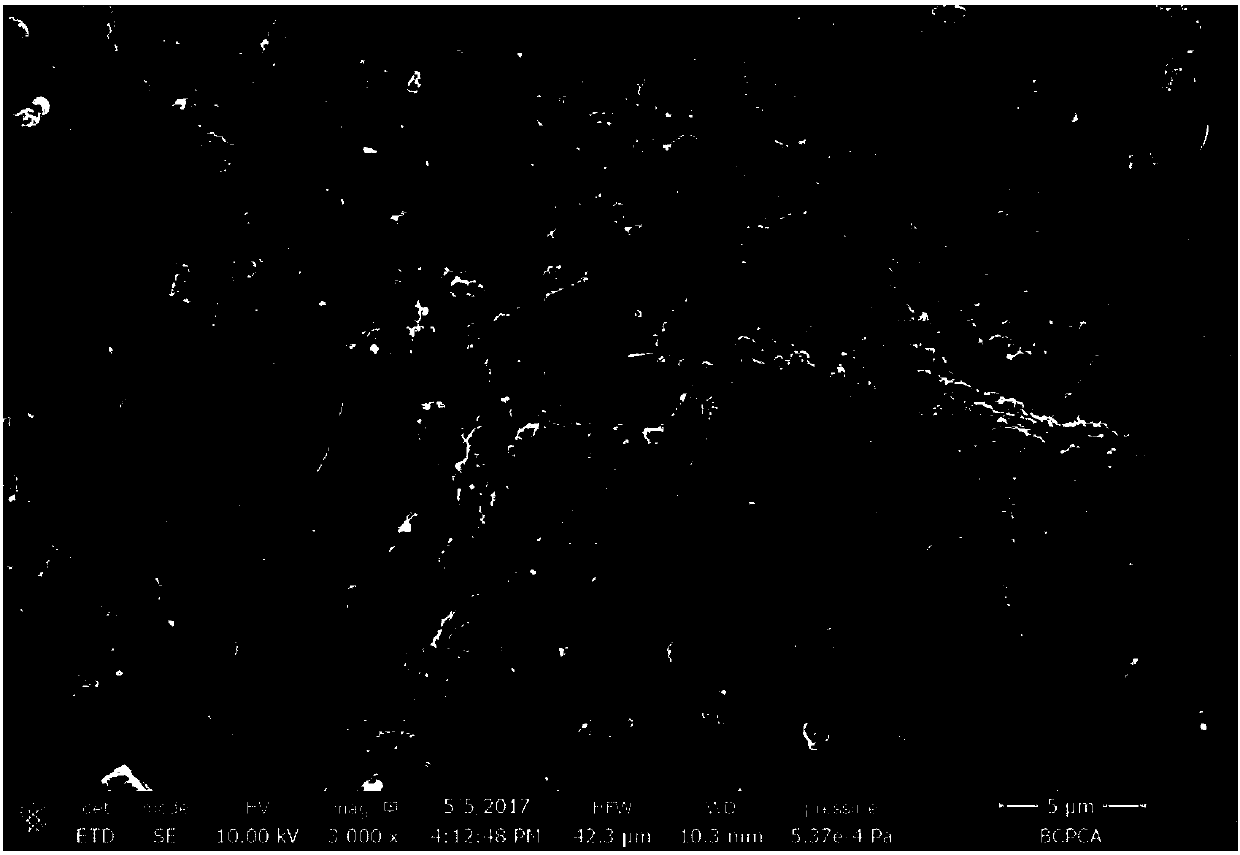

[0035] A method for preparing a graphene electrothermal material with controllable electrothermal properties, comprising:figure 1 The graphene slurry shown (the graphene slurry of Hongna New Material Technology Co., Ltd. can be used) is used as a conductive filler, and the water-based polyurethane emulsion (the water-based polyurethane emulsion of Shanghai Birong Chemical Co., Ltd. can be used) is used as a binder. And adding a mass fraction of 3% water-based emulsifier (the water-based emulsifier of Shanghai Zhongcheng Fine Chemical Co., Ltd. can be used), so as to obtain a graphene electrothermal carbon slurry with a graphene slurry content of 80wt%. With polyethylene terephthalate PET film as carrier, set 2 wires on PET film, and the distance between two adjacent wires is 2cm, then described graphene electrothermal carbon paste is coated on On the wire and the PET film, dry it at 120°C, so as to make the figure 2 Graphene electrocaloric material with controllable electroca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com