Preparation method of hydrogen chloride oxidation catalyst

A technology of oxidation catalyst and hydrogen chloride, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, preparation with chloride, etc., which can solve the problem of low utilization efficiency of precious metal ruthenium, difficulty in industrial scale-up preparation, and water consumption Large and other problems, to achieve the effect of overcoming energy consumption and pollution, improving production yield, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

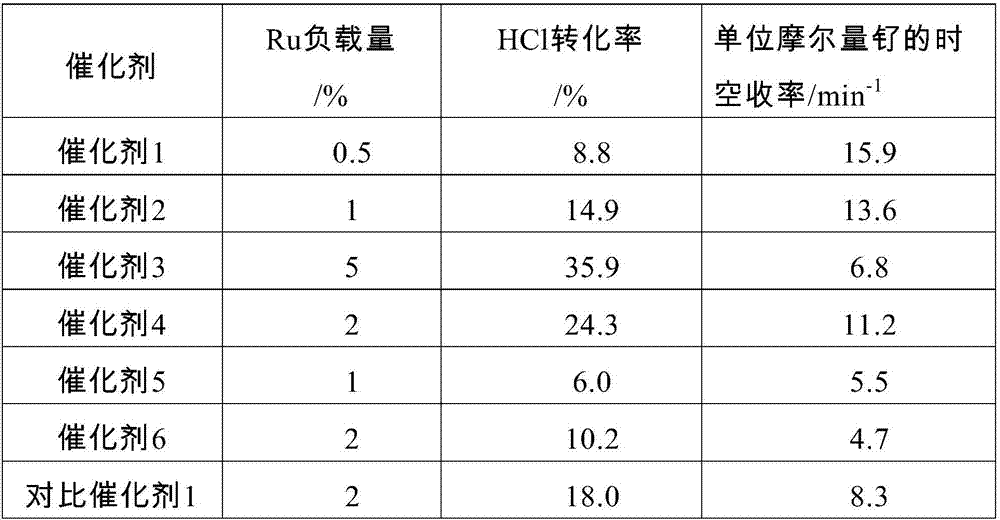

Embodiment 1

[0028] The present embodiment provides a kind of preparation method of hydrogen chloride oxidation catalyst, and this method comprises the following steps:

[0029] Step 1, 0.14g commercially available RuCl 3 .nH 2 O (Ru mass content > 37%) was added to 50 g of distilled water to obtain a solution with a ruthenium mass content of 0.1%, named solution one;

[0030] Step 2, adding 20 g of commercially available 30% hydrogen peroxide into 20 g of distilled water to obtain a solution with a hydrogen peroxide content of 15%, named solution 2;

[0031] Step 3: According to the molar ratio of the ruthenium precursor, hydrogen peroxide, and titanium dioxide is 0.3:0.5:100, add the powdered titanium dioxide carrier (rutile type, Aladdin reagent) into the solution 1, and stir fully to obtain the solution 3; then add two drops of the solution Add solution three to obtain solution four;

[0032] Step 4: Warm up solution 4 to 80°C and keep it for 4 hours to obtain solution 5;

[0033] ...

Embodiment 2

[0037] The present embodiment provides a kind of preparation method of hydrogen chloride oxidation catalyst, and this method comprises the following steps:

[0038] Step 1, 0.68g of commercially available RuCl 3 .nH 2 O (Ru mass content > 37%) was added to 50 g of distilled water to obtain a solution with a ruthenium mass content of 0.5%, named solution one;

[0039] Step 2, add 20 g of commercially available 50% hydrogen peroxide to 20 g of distilled water to obtain a solution with a hydrogen peroxide content of 25%, which is named solution 2;

[0040] Step 3: According to the molar ratio of the ruthenium precursor, hydrogen peroxide, and titanium dioxide is 0.6:2:100, add the powdered titanium dioxide carrier (rutile type, Aladdin reagent) into the solution 1, and stir fully to obtain the solution 3; then add two drops of the solution Add solution three to obtain solution four;

[0041] Step 4: Warm up solution 4 to 90°C and keep it for 2 hours to obtain solution 5;

[0...

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of hydrogen chloride oxidation catalyst, and this method comprises the following steps:

[0047] Step 1, 7.81g commercially available RuCl 3 .nH 2 O (Ru mass content > 37%) was added to 50 g of distilled water to obtain a solution with a ruthenium mass content of 5%, named solution one;

[0048] Step 2, a solution with a commercially available hydrogen peroxide content of 35%, named as solution 2;

[0049] Step 3: According to the molar ratio of the ruthenium precursor, hydrogen peroxide, and titanium dioxide is 3:10:100, add the powdered titanium dioxide carrier (rutile type, Aladdin reagent) into the solution 1, and stir fully to obtain the solution 3; then add two drops of the solution Add solution three to obtain solution four;

[0050] Step 4: Warm up solution 4 to 90°C and keep it for 2 hours to obtain solution 5;

[0051] Step 5, the pH of the solution 5 is adjusted to 6 or more with sodium metasili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com