A post-treatment process for solution polymerization

A solution and polymer technology, applied in the field of polymer post-processing, can solve the problems of deactivating agent, terminating agent residue, removing deactivating agent, terminating agent, insufficient polymerization activity, etc. The effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Polymers can be prepared using techniques known in the art, such as solution polymerization, slurry polymerization, bulk polymerization and other methods. For example, it may be solution polymerization of α-olefin and cycloolefin, or polymerization of α-olefin and other monomers having polymerizable groups. The polymerization is carried out in the presence of a polymerization catalyst, which may be a commonly used catalyst in the art, such as a metallocene catalyst, a non-metallocene catalyst, or the like. In addition, in order to improve the polymerization efficiency, a co-catalyst is used in combination with the catalyst.

[0056] As cocatalysts, aluminoxanes and aluminum alkyls can be used.

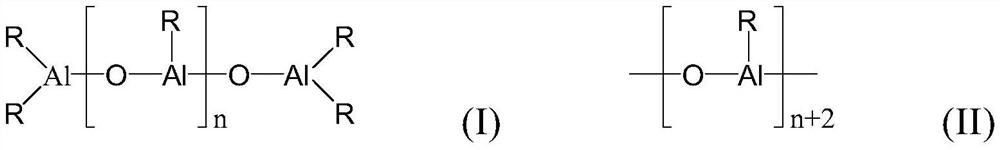

[0057] As the aluminoxane, for example, a linear aluminoxane represented by the following general formula (I): (R)(R)Al-(Al(R)-O) n -O-Al(R)(R), and a cyclic aluminoxane represented by the following general formula (II): -(Al(R)-O-) n+2 -.

[0058]

[0059] In the aforeme...

Embodiment 1

[0105] Polymerization reaction of ethylene-norbornene copolymer, using toluene as solvent, main catalyst is 3,5-di-tert-butyl salicylidene 2-methylthioaniline titanium trichloride, co-catalyst is MAO, chain transfer agent For triethylaluminum. The amount of solvent added is 1L, so that the main catalyst concentration is 4×10 -5 mol / L, add MAO so that the ratio of MAO to aluminum and titanium is 1000:1, add triethylaluminum so that the ratio of triethylaluminum to aluminum and titanium is 20:1, the polymerization temperature is 75°C, the polymerization pressure is 0.2MPa, the reaction time for 15 minutes. After the polymerization reaction is completed, post-treatment is performed. The specific post-processing process is:

[0106] The toluene solution of ethylene-norbornene copolymer from the polymerization unit first enters the gas and liquid phase removal unit, which contains 3 flash tanks, and the pressure of the flash tank is controlled at 0.01MPa. In this unit, ethylene,...

Embodiment 2

[0113] Except that the reclaimed MAO solution obtained in Example 1 was used as the cocatalyst, the polymerization conditions, polymerization process and post-treatment process were the same as in Example 1.

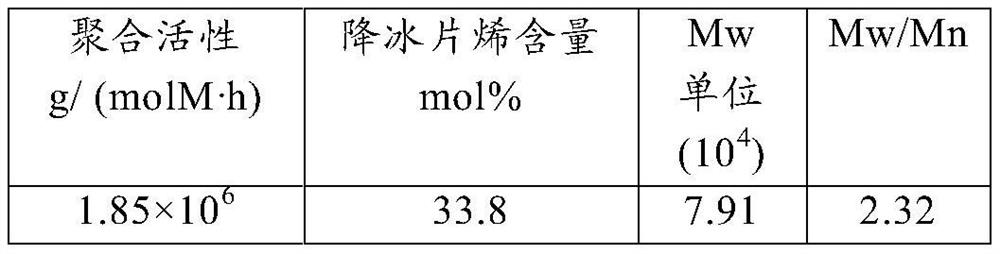

[0114] The recovery of recovered MAO was determined to be 85%. Polymerization activity and polymer physical properties test are shown in the following table:

[0115]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com