Anticorrosive paint composition, method for preparing anticorrosive paint and anticorrosive paint

A technology for anti-corrosion coatings and compositions is applied in the fields of anti-corrosion coating compositions and the preparation of anti-corrosion coatings and anti-corrosion coatings. The effect of high corrosion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 0.5g of graphene powder into 100ml of N,N-dimethylformamide, ultrasonically disperse at a frequency of 20 Hz for 2 hours, then add 0.5g of γ-aminopropyltrimethoxysilane and 0.5g of distilled water, and mechanically Stir and react for 24 hours. After the reaction, use suction filtration to obtain a black powdery solid product, i.e. organosilane-modified graphene; add 0.3g of the above-mentioned organosilane-modified graphene to 80mlN, in N-dimethylformamide, Then add 10 g of polyurethane, ultrasonically disperse at a frequency of 20 Hz for 2 hours, and then mechanically stir for 24 hours to remove N,N-dimethylformamide to obtain a graphene / polyurethane composite material.

[0047] With the bisphenol A type epoxy resin (weight average molecular weight is 10000) of 50 weight parts, the fluorocarbon resin (weight average molecular weight is 5000) of 50 weight parts, the 20-50 purpose first active carbon of 0.5 weight part, 10 weight parts 100-200 mesh second activated c...

Embodiment 2

[0050] The graphene / polyurethane composite material of this embodiment is consistent with embodiment 1.

[0051] With the bisphenol A type epoxy resin (weight average molecular weight is 10000) of 60 weight parts, the fluorocarbon resin (weight average molecular weight is 5000) of 40 weight parts, the first active carbon of the 20-50 purpose of 0.3 weight part, 12 weight parts 100-200 mesh second activated carbon, 6 parts by weight of solvent ethylene glycol, 2 parts by weight of dispersant (Disperbyk191), and 1 part by weight of defoamer (BYK053) were mixed and stirred for 30min, and then ground in a sander , and then the resulting mixture was mixed with 11 parts by weight of the graphene / polyurethane composite material and stirred for 1 h to obtain the anti-corrosion coating prepared in this embodiment.

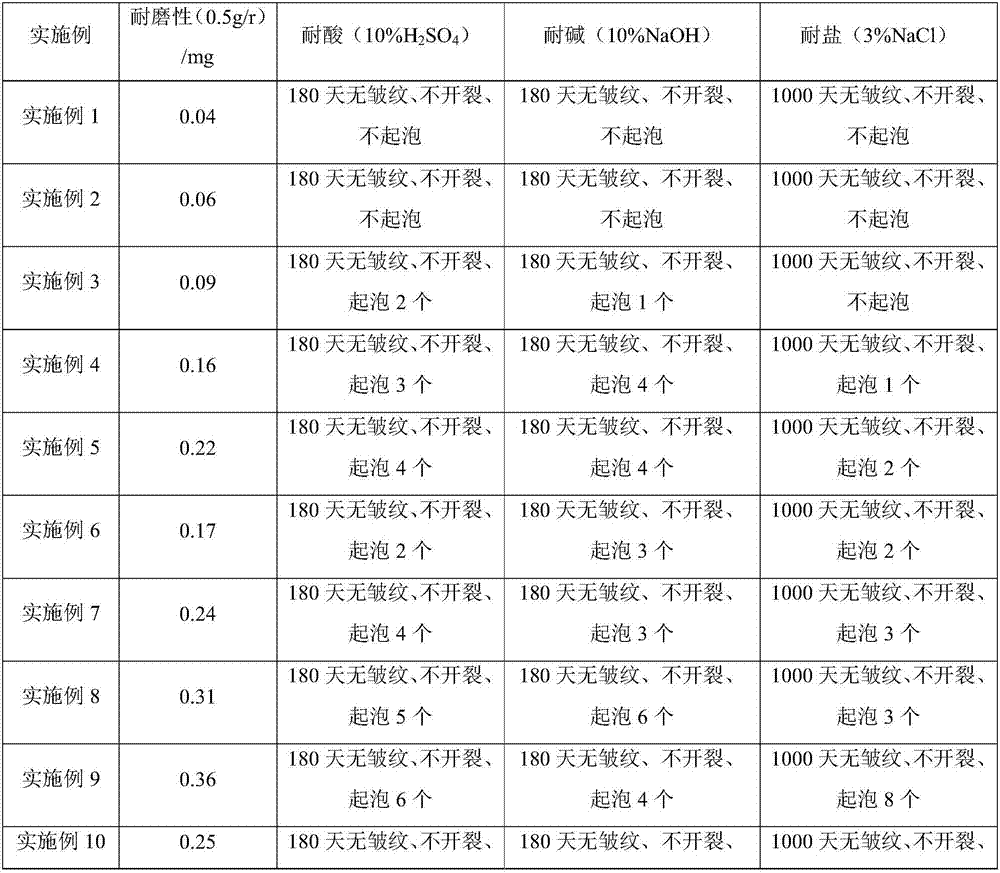

[0052] The wear resistance and anticorrosion performance of the anticorrosion coating were tested, and the test results are shown in Table 1.

Embodiment 3

[0054] The graphene / polyurethane composite material of this embodiment is consistent with embodiment 1.

[0055] With the bisphenol A type epoxy resin (weight-average molecular weight is 10000) of 50 weight parts, the fluorocarbon resin (weight-average molecular weight is 5000) of 50 weight parts, the first active carbon of the 20-50 purpose of 0.5 weight part, 25 weight parts 100-200 mesh second activated carbon, 2 parts by weight of solvent n-butanol, 0.1 parts by weight of dispersant (Disperbyk191), and 0.1 parts by weight of defoamer (BYK 053) were mixed and stirred for 30min, and then carried out in a sander After grinding, the resulting mixture was mixed with 18 parts by weight of graphene / polyurethane composite material and stirred for 1 hour to obtain the anticorrosion coating prepared in this example.

[0056] The wear resistance and anticorrosion performance of the anticorrosion coating were tested, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com