High-strength flame-retardant polyurethane sealant for high-speed rail passenger cars and preparation method thereof

A technology of polyurethane sealant and high-speed rail, applied in the direction of polyurea/polyurethane adhesive, chemical instruments and methods, adhesives, etc., can solve the problem that it is difficult to meet the performance requirements of high-speed rail cars, and polyurethane sealant is difficult to meet the strength and flame retardancy Requirements and other issues, to achieve the effect of high strength, wide application range and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

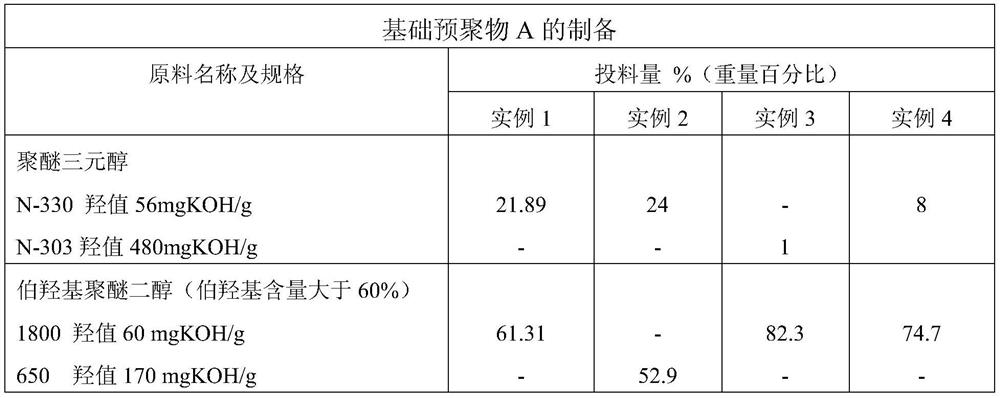

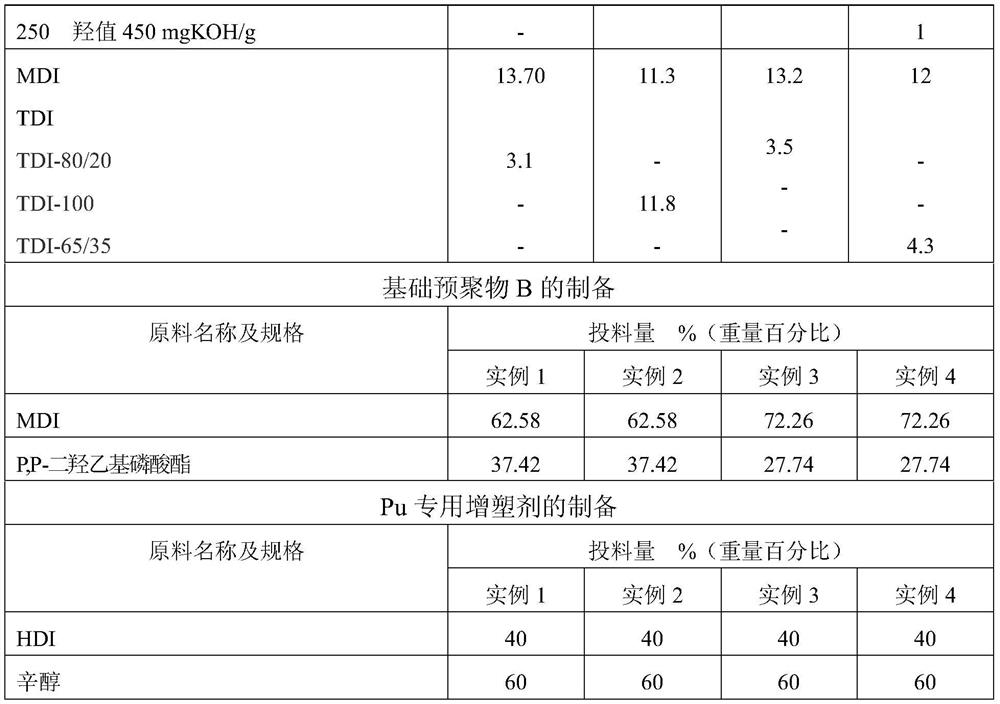

[0051] According to the formulation amount shown in Table 1 below, take a selected amount of primary hydroxyl polyether diol and polyether triol into the reaction kettle, heat to 120°C, and vacuum dehydrate for 2 hours at a vacuum degree of -0.09MPa to reach the water content <0.05%, then lower the temperature to 60°C, add the selected MDI and TDI in proportion while stirring, then raise the temperature to 80°C for 4 hours, then cool to about 60°C to obtain prepolymer A.

[0052] According to the formulation amount shown in Table 1 below, take a selected amount of P,P-dihydroxyethyl phosphate and put it into the reactor, heat it to 120°C, and vacuum dehydrate it for 2 hours at a vacuum degree of -0.09MPa until the water content is < 0.05%, then lower the temperature to 60°C, add a selected amount of MDI in proportion while stirring, then raise the temperature to 80°C to react for 4 hours, and cool to about 60°C to obtain prepolymer B.

[0053] In Examples 1-4, the above prepol...

Embodiment 5

[0060] The base prepolymer and PU plasticizer were prepared according to the raw materials and ratios in Example 1 in Table 1 above.

[0061] The above-mentioned basic prepolymer 30kg, PU plasticizer 20kg, filler (calcium carbonate 25.6kg, talcum powder 4.8kg, titanium dioxide 0.96kg, fumed silica 0.64kg) 32kg, stabilizer (p-toluenesulfonic acid group isocyanate ) 1kg, solvent (methylcyclohexane) 15kg, auxiliary agent (kh560 coupling agent) 2kg, add to the planetary mixer, stir at high speed under vacuum until uniform and free of particles, and the polyurethane sealant can be obtained.

Embodiment 6

[0063] The base prepolymer and PU plasticizer were prepared according to the raw materials and ratios in Example 2 in Table 1 above.

[0064] The above-mentioned basic prepolymer 70kg, PU plasticizer 5kg, filler (calcium carbonate 36kg, titanium dioxide 3.2kg, fumed silica 0.8kg) 40kg, catalyst (p-toluenesulfonic acid isocyanate) 1kg, solvent (methyl Add 5kg of cyclohexane, 5kg of dimethyl carbonate) and 10kg into a planetary mixer, and stir at high speed under vacuum until it is uniform and free of particles, and then the polyurethane sealant can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com