Low-odor stainless steel cold-rolled sheet rolling oil

A cold-rolled thin plate and rolling oil technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of increased cost of rolling oil, human hazards, irritating odor, etc., and achieves cleanliness of the plate surface and low cost , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

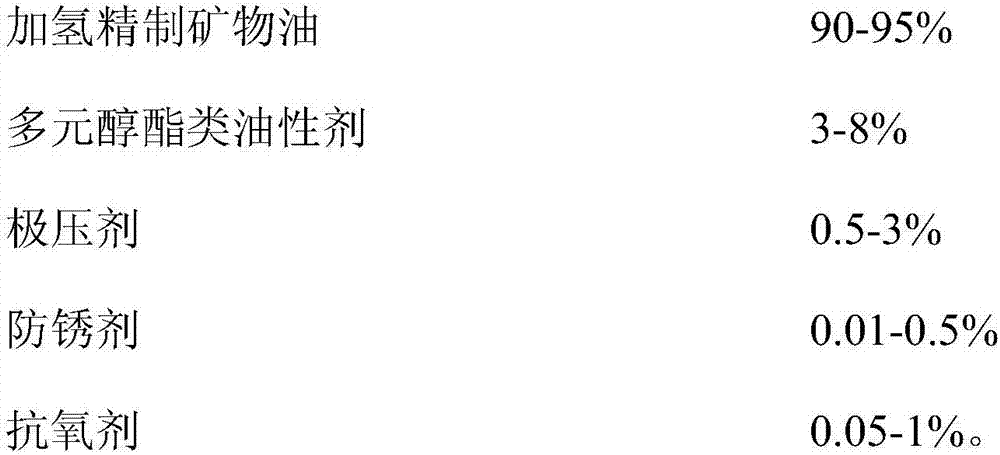

[0027] The raw material for preparing rolling oil provided in this embodiment includes the following components in terms of mass percentage:

[0028]

[0029] Among them, the hydrorefined mineral oil is 60N; the oiliness agent is trimethylolpropane oleate; the molecular weight of the extreme pressure agent is 12,000; the rust inhibitor is a combination of alkenyl succinic acid and benzotriazole derivatives, two The mass ratio of the two is 2:3; the antioxidant is dialkyl diphenylamine.

Embodiment 2

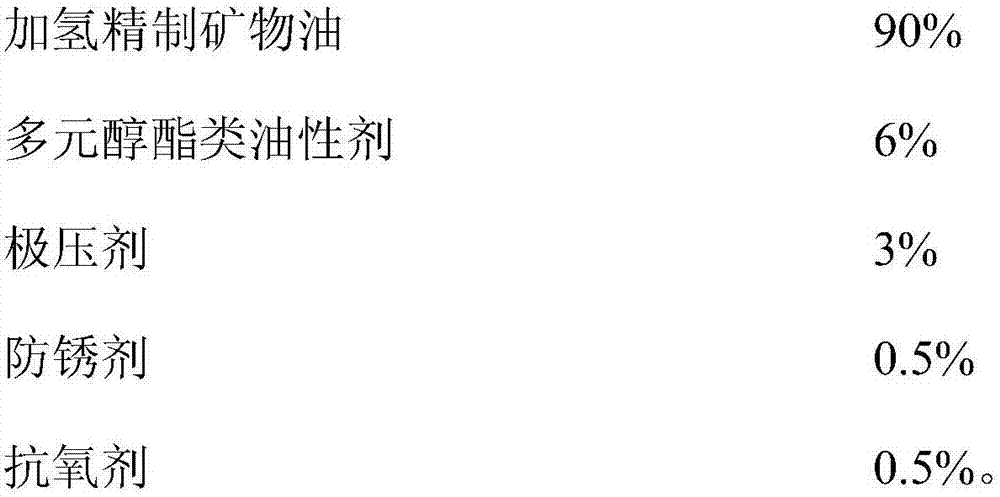

[0031] The raw material for preparing rolling oil provided in this embodiment includes the following components in terms of mass percentage:

[0032]

[0033] Among them, the hydrorefined mineral oil is 70N; the oiliness agent is pentaerythritol oleate; the molecular weight of the extreme pressure agent is 25,000; the rust inhibitor is a combination of alkenyl succinic acid and benzotriazole derivatives, and the mass ratio of the two It is 2:3; the antioxidant is dialkyldiphenylamine and 2,6-di-tert-butylphenol, and the mass ratio of the two is 1:1.

Embodiment 3

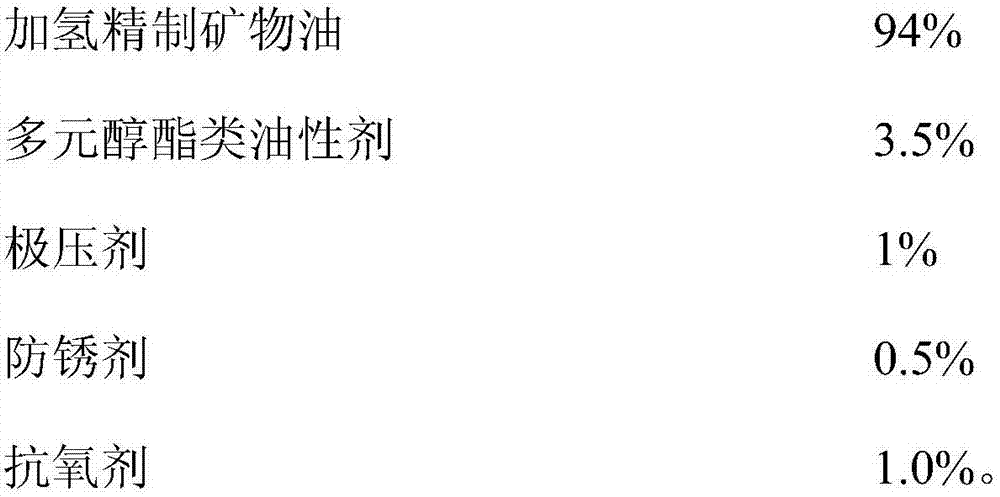

[0035] The raw material for preparing rolling oil provided in this embodiment includes the following components in terms of mass percentage:

[0036]

[0037] Among them, the hydrorefined mineral oil is a composition of 60N and 70N, and the mass ratio of the two is 1:1; the oiliness agent is trimethylolpropane oleate; the molecular weight of the extreme pressure agent is 20,000; the rust inhibitor is fatty acid amide The mass ratio of the composition with benzotriazole derivative is 2:1; the antioxidant is dialkyldiphenylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com