A kind of preparation method of granular xanthate

A xanthate and granular technology is applied in the field of preparing granular xanthate, which can solve the problems of irritating odor of xanthate, high product production cost, environmental pollution of manufacturers, etc., and achieves elimination of irritating odor, easy recycling, Realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

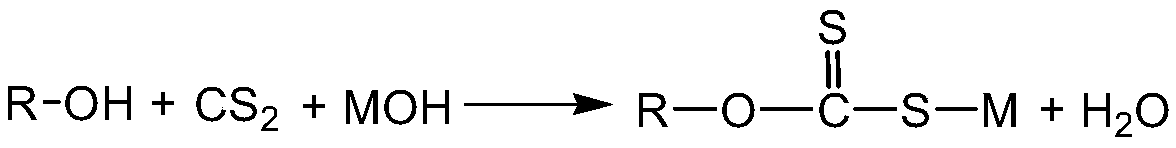

[0032] The preparation of embodiment 1 granular isobutyl xanthate

[0033]With the ratio of 101.19 parts of dichloromethane and carbon disulfide substance being 1:1 mixture as solvent, 29.95 parts of purity is 99% isobutanol and 32.31 parts of purity are 99% carbon disulfide is added in the reactor, under stirring The mixture was cooled to about 15°C, then 16.68 parts of granular sodium hydroxide (96% purity) was added to the reactor, stirred and reacted at 25°C for 2 hours, 0.75 parts of eucalyptol was added, stirred evenly, and then Distill under reduced pressure at 60°C for 1 hour to remove the solvent and water. After the solvent and water were allowed to stand and separate into layers, the solvent was recovered, and the obtained powdery isobutylxanthate was compressed with a 769YP-15A powder tablet press to obtain Φ5×8 (mm) xanthate granules, no irritating odor of xanthate, slightly faint fragrance. It has a certain hardness, 1.0 meters away from the hard ground, free fa...

Embodiment 2

[0034] The preparation of embodiment 2 granular isobutyl xanthates

[0035] Add 133.50 parts of carbon disulfide and 29.95 parts of isobutanol with a purity of 99% into the reactor, and cool the mixture to about 15°C under stirring, then add 16.68 parts of flaky sodium hydroxide (96% in purity) to the reaction In the container, stir and react at 25°C for 2 hours, add 0.75 parts of camphor, stir evenly, and then distill under reduced pressure at 60°C for 1 hour to remove solvent and water. After the solvent and water are separated and separated, the solvent is recovered. The prepared powdery isobutyl xanthate is tableted with a 769YP-15A powder tablet press to obtain Φ5×8 (mm) xanthate granules, without xanthate irritating odor, slightly faint camphor fragrance, and has a certain hardness , 1.0 meters away from the hard ground, free fall 10 times without breaking, good solubility in water. The analysis showed that the purity of the isobutyl xanthate product was 95.91%, the moi...

Embodiment 3

[0036] The preparation of embodiment 3 granular isobutyl xanthates

[0037] Add 101.19 parts of dichloromethane, 29.95 parts of isobutanol with a purity of 99% and 32.31 parts of carbon disulfide with a purity of 99% into the reactor, and cool the mixture to about 15°C under stirring, and then add 16.68 parts of granular sodium hydroxide (96% purity) was added to the reactor, stirred and reacted at 25°C for 2 hours, added 0.75 parts of additives (the mass ratio of eucalyptol to camphor was 1:1), stirred evenly, and then decompressed at 60°C Distill for 1 hour to remove the solvent and water. After the solvent and water were allowed to stand for stratification, the solvent was recovered, and the obtained powdery isobutylxanthate was compressed with a 769YP-15A powder tablet machine to obtain Φ5×8 (mm ) Xanthate granules, no irritating odor of xanthate, slightly faint camphor fragrance. It has a certain hardness, 1.0 meters away from the hard ground, free fall 10 times without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com