Peanut oil and preparation method thereof

A peanut oil and peanut technology, applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc. It can solve the problems of high cost of aroma production by enzymatic hydrolysis, affecting production, and large restrictions, and achieves the reduction of the content of bad flavor substances in oil, The effect of increased proportion and pure flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

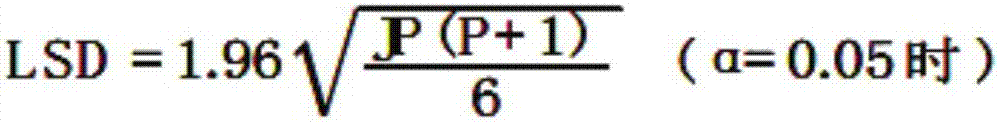

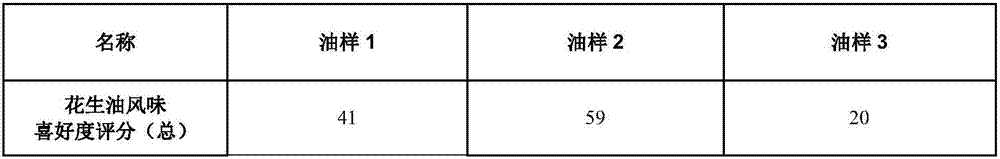

[0052] The effect of the addition position of embodiment 1 bentonite on the flavor of peanut oil

[0053] Peanut raw materials are pretreated by magnetic separation to remove iron, vibrating sieve to remove impurities, and specific gravity stoner to remove stones. According to the total weight of peanut raw materials after removal of impurities, they are divided into 20% Xiaolu peanut oil and 80% Dalu peanuts. Xiaolu peanuts are roasted and broken to 6-8 petals in a frying furnace, and Dalu peanuts are crushed to 6-8 petals, and then the embryos are rolled to a thickness of 3-5mm. They are put into a YZC-L-type steamer, and the bottom of the steamer is controlled. The moisture content of the steamed embryo flakes is less than 6%. Put the stir-fried material and the steamed material into the homogeneous pot and mix for 10 minutes, keep the pressing temperature at 135°C, send the mixed material to the Y-280 screw press device, add 1% water relative to the weight of the crude oil...

Embodiment 2

[0069] The impact of the different additions of embodiment 2 bentonite on the flavor of peanut oil

[0070] Change the add-on of bentonite at the mixing place of frying material and steaming material, add respectively 0.1% weight, 0.3% weight, 0.5% weight, 1% weight of bentonite adsorbent relative to the weight of the embryo, other preparation processes are the same as those in Example 1 Oil sample 2 is consistent.

[0071] Determination of flavor substances:

[0072] Table 4 Effects of different bentonite adsorbent additions on flavor substances of peanut oil

[0073]

[0074]

[0075] Table 5 Effects of different bentonite adsorbent additions on flavor substances of peanut oil

[0076]

[0077] Note: The proportion of bad flavor substances = content of bad flavor substances / total flavor substances * 100%

[0078] Proportion of pyrazine flavor substances = content of pyrazine flavor substances / total flavor substances * 100%

[0079] The above table shows that...

example 3

[0084] Influence of example 3 different adsorption times on the removal of aflatoxin in peanut oil and peanut meal

[0085] After the steamed and fried peanuts are mixed, the steamed and fried materials after adding 0.3% bentonite relative to the weight of the total embryo are mixed in a small frying pan for 10 minutes, 20 minutes, and 30 minutes respectively, and then enter the screw press machine. Other steps are the same as the preparation process of oil sample 2 in Example 1.

[0086] Determination of flavor substances:

[0087] Table 7 The effect of adsorbent adsorption time on the flavor of peanut oil

[0088]

[0089]

[0090] Table 8 The influence of adsorbent adsorption time on the flavor of peanut oil

[0091]

[0092]It can be seen from the experimental results that the total amount of flavor substances in peanut oil decreased significantly with the increase of adsorption time of bentonite adsorbent, and the adsorption effect tended to be stable after 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com