Method for in-situ electrochemical fluorination of lithium titanate and prepared fluorinated lithium titanate battery

An in-situ electrochemical, lithium fluoride titanate technology, used in electrochemical generators, electrode manufacturing, battery electrodes, etc., can solve problems such as poor rate performance, achieve strong operability, large industrial application value, high Effects of Capacity and Cycling Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

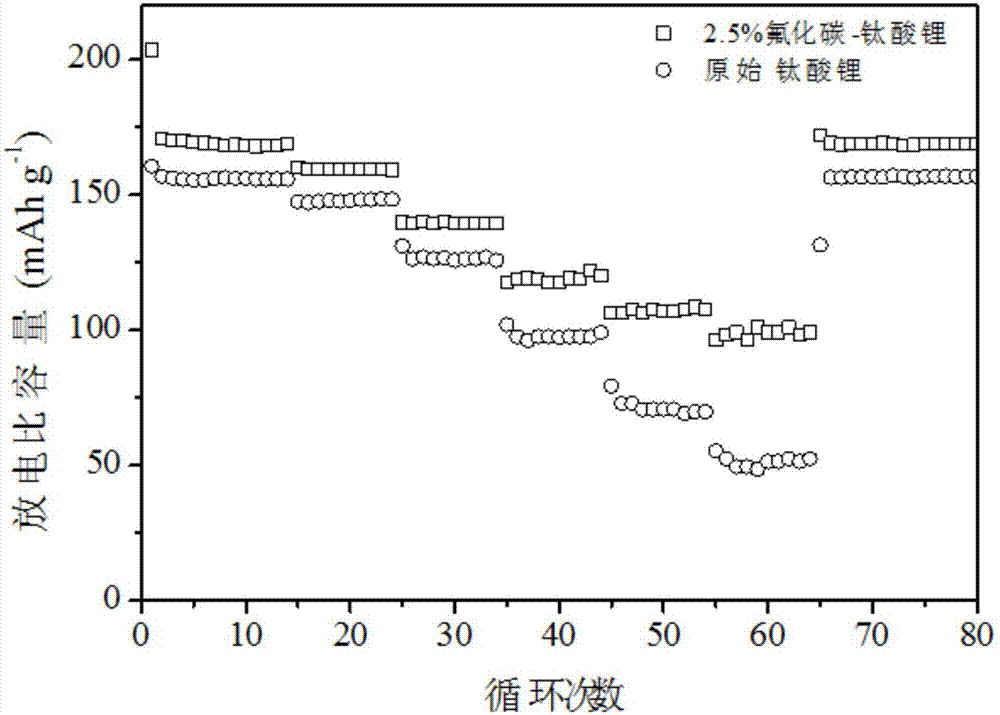

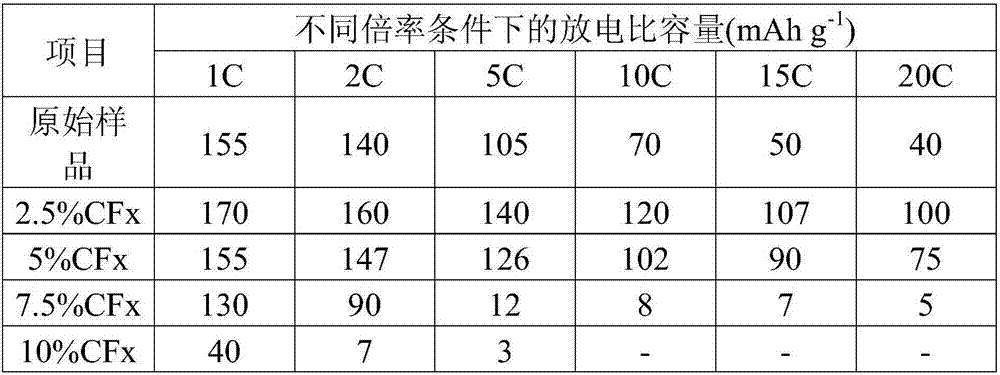

Embodiment 1

[0035] (1) Preparation of in-situ electrochemical lithium fluoride titanate pole piece:

[0036] The active material lithium titanate Li 4 Ti 5 o 12 , conductive carbon black, fluorinated carbon, and binder polyvinylidene fluoride (PVDF) are mixed with solvent N-methylpyrrolidone (NMP) at a mass ratio of 80:7.5:2.5:10 to make a slurry, and then the slurry Evenly coated on the current collector aluminum foil, vacuum dried and punched into 14mm pole pieces.

[0037] (2) Assemble lithium titanate lithium ion battery:

[0038] Put the metal lithium sheet, diaphragm and the above pole piece in sequence in the CR2016 button battery case, and add an appropriate amount of electrolyte LiPF 6 (EC:DMC 3:7) to obtain a lithium titanate lithium ion battery.

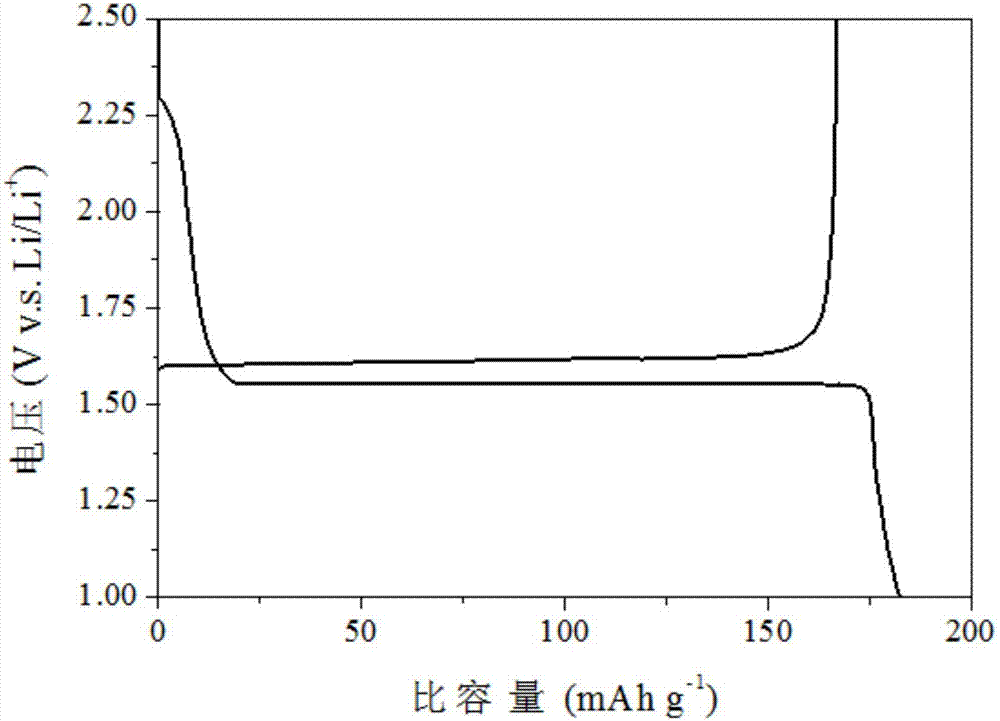

[0039] (3) The first discharge formation of lithium titanate lithium ion battery (in situ electrochemical fluorination process):

[0040] On the charge and discharge equipment, the formation current is calculated at 0.1C accordi...

Embodiment 2

[0044] The preparation of the in-situ electrochemical lithium fluoride titanate battery is the same as in Example 1 except that the carbon fluoride feed ratio is different. Fluorocarbon feed mass ratio is 5%.

Embodiment 3

[0046] The preparation of the in-situ electrochemical lithium fluoride titanate battery is the same as in Example 1 except that the carbon fluoride feed ratio is different. The feed mass ratio of fluorocarbon is 7.5%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap