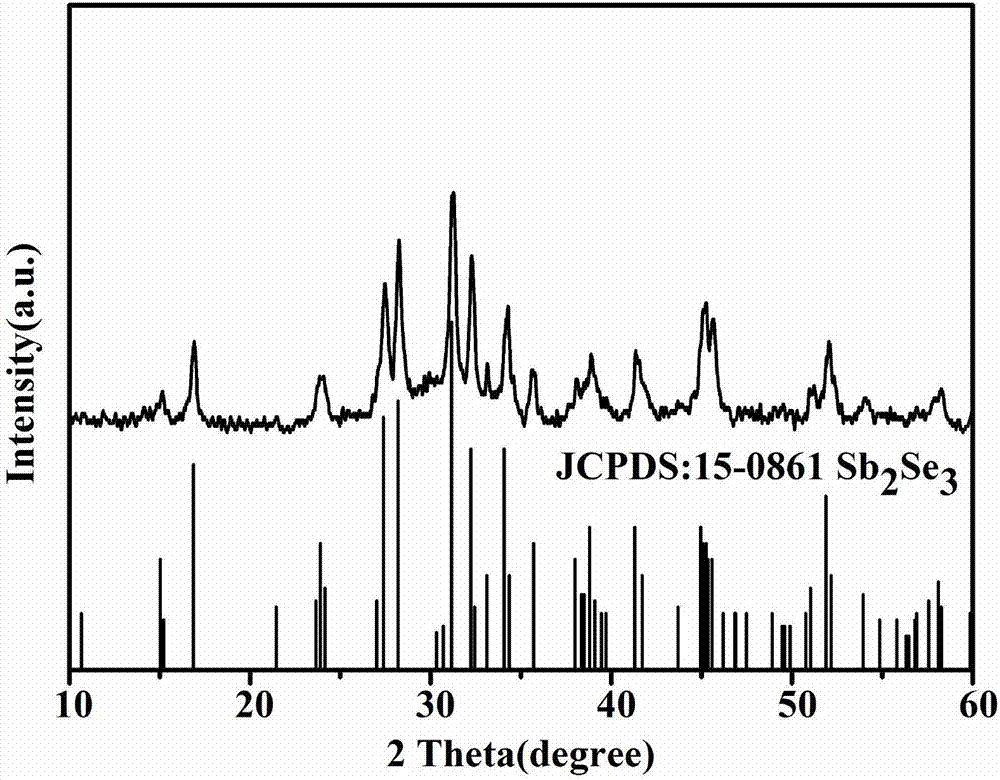

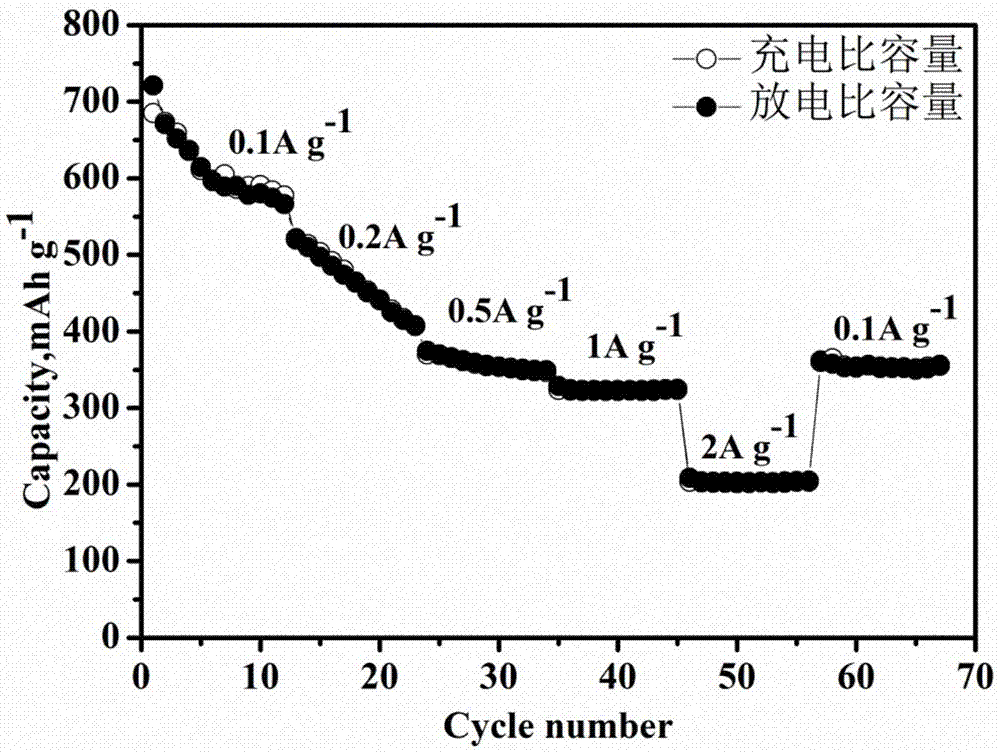

Method for preparing flaky Sb2Se3 nanocrystalline for sodium-ion battery negative electrodes

A sodium-ion battery and nanocrystal technology, applied in the field of electrochemical energy storage, can solve the problems of few reports and achieve the effects of simple equipment, excellent rate performance, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Add 0.001g of polyvinylpyrrolidone and 0.2g of tartaric acid into 25ml of deionized water, stir magnetically at 500r / min until it is completely dissolved to obtain a transparent solution A1, then add 0.169g of antimony potassium tartrate into solution A1 for Stir to obtain a transparent solution A2, wherein the molecular weight of polyvinylpyrrolidone is 30000;

[0021] 2) According to the molar ratio of antimony potassium tartrate and sodium selenite being 1:1, sodium selenite was added to 3 mL of hydrazine hydrate with a mass percentage of 50%, and magnetically stirred at 500 r / min to obtain wine red solution B; stir Add solution B quickly dropwise to solution A2, stir and disperse evenly to obtain mixed solution C;

[0022] 3) Transfer the mixed solution C to the polytetrafluoroethylene lining at a filling ratio of 30%, put it into a homogeneous reactor, and keep it at 100°C for 12 hours, then cool it to room temperature with the furnace, and use deionized water a...

Embodiment 2

[0024] 1) Add 0.002g of polyvinylpyrrolidone and 0.5g of tartaric acid into 45ml of deionized water, stir magnetically at 600r / min until it is completely dissolved to obtain a transparent solution A1, and then add 0.338g of antimony potassium tartrate into solution A1 to continue Stir to obtain a transparent solution A2, wherein the molecular weight of polyvinylpyrrolidone is 30000;

[0025] 2) Add sodium selenite to 5 mL of hydrazine hydrate with a mass percentage of 50% according to the molar ratio of antimony potassium tartrate and sodium selenite at a molar ratio of 1:1.5, and magnetically stir at 600 r / min to obtain wine red solution B; stir Add solution B quickly dropwise to solution A2, stir and disperse evenly to obtain mixed solution C;

[0026] 3) Transfer the mixed solution C to the polytetrafluoroethylene lining at a filling ratio of 50%, put it into a homogeneous reactor, and keep it at 120°C for 8 hours, then cool it to room temperature with the furnace, and use ...

Embodiment 3

[0028]1) Add 0.003g of polyvinylpyrrolidone and 1.0g of tartaric acid into 53ml of deionized water, stir magnetically at 500r / min until it is completely dissolved to obtain a transparent solution A1, then add 0.6759g of antimony potassium tartrate into solution A1 for Stir to obtain a transparent solution A2, wherein the molecular weight of polyvinylpyrrolidone is 30000;

[0029] 2) According to the molar ratio of potassium antimony tartrate and sodium selenite of 1:2, sodium selenite was added to 7 mL of hydrazine hydrate with a mass percentage of 50%, and magnetically stirred at 500 r / min to obtain wine red solution B; stir Add solution B quickly dropwise to solution A2, stir and disperse evenly to obtain mixed solution C;

[0030] 3) Transfer the mixed liquid C to the polytetrafluoroethylene lining at a filling ratio of 60%, put it into a homogeneous reactor, and keep it at 130°C for 6 hours, then cool it to room temperature with the furnace, and use deionized water and anh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com