Micro-nano structure Al-FeF3 compound fuel and preparation method thereof

A composite fuel, al-fef3 technology, which is applied to explosive composite components, offensive equipment, explosive processing equipment, etc. Equipment and process requirements are relatively high, to achieve the effect of good air tightness, simple equipment and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

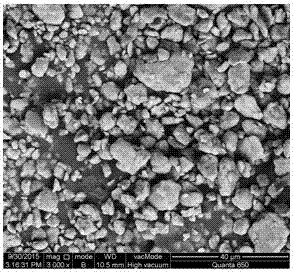

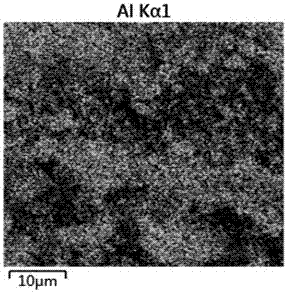

Embodiment 1

[0039] 40 grams of 300-500μm aluminum powder, FeF 3 2 grams, and 1.5 grams of stearic acid were added to two 250ml stainless steel ball milling jars in turn, and about 400 grams of stainless steel balls were added to the two ball milling jars, and the ball milling jars were fixed symmetrically in the planetary high-energy ball mill with a cover. Set the process parameters: the speed is 400 rpm, the working time is 12 hours, and the ball milling method is continuous operation. Turn on the ball mill for high-energy ball milling.

[0040] After the ball milling, open the cover in the glove box and place it for 24 hours, then transfer the ball-milled composite aluminum powder to a 500ml beaker, add about 200ml cyclohexane and stir well. Transfer the beaker to a fume hood until the n-hexane volatilizes slowly and completely. Use 100ml ethyl acetate to wash the composite aluminum powder 3 times, dry after filtering, and obtain 40.5 grams of solid powder Al-FeF 3 Composite metal ...

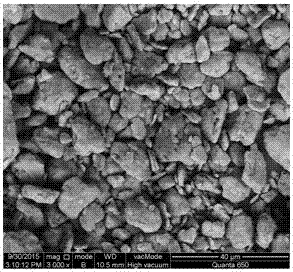

Embodiment 2

[0046] 40 grams of 20-50μm aluminum powder, FeF 3 Add 1.2 grams and 1.0 grams of stearic acid into two 250ml stainless steel ball milling jars in turn, add about 320 grams of stainless steel grinding balls to the two ball milling jars respectively, and fix the ball milling jars symmetrically in the planetary high-energy ball mill with a cover. Set the process parameters: the speed is 300 rpm, the working time is 8 hours, the ball milling method is ball milling for 5 minutes, and the machine stops for 30 seconds. Turn on the ball mill for high-energy ball milling.

[0047] After the ball milling, open the cover in the glove box and place it for 24 hours, then transfer the ball-milled composite aluminum powder to a 500ml beaker, add about 150ml cyclohexane and stir well. Transfer the beaker to a fume hood until the n-hexane volatilizes slowly and completely. Use 100ml ethyl acetate to wash the composite aluminum powder 3 times, dry after filtering, and obtain 39.8 grams of so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com