Acrylamide monomer, preparation method and acrylamide polymer thereof, and application of acrylamide polymer

A technology of acrylamide and polymer, applied in the application of polymer oil displacement agent, acrylamide polymer, acrylamide monomer and its preparation field, can solve the problems of poor tolerance, troublesome construction, increased loss, etc. Achieve excellent temperature and salt resistance and shear resistance, and improve the effect of salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

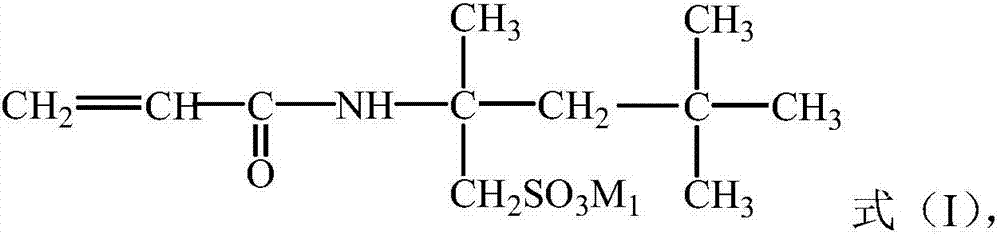

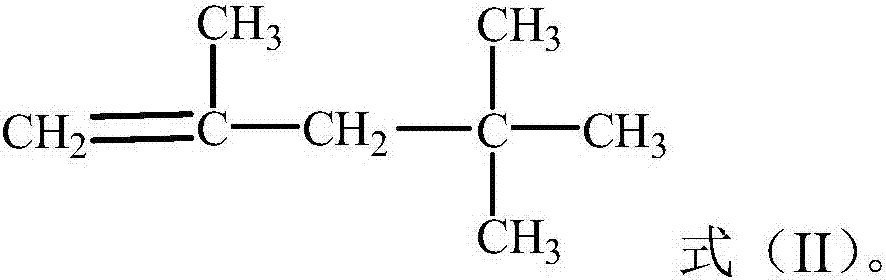

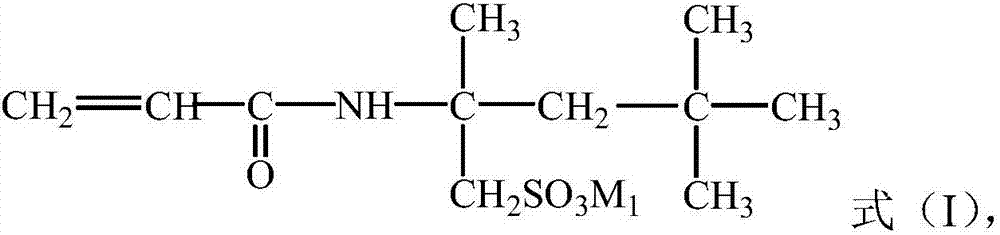

[0020] The method for preparing acrylamide monomers provided by the present invention comprises: reacting diisobutylene, acrylonitrile and a sulfonating agent represented by formula (II) for 2-16 hours at a temperature ranging from -5°C to 30°C ( Thereby obtaining the acrylamide monomer shown in formula (I),

[0021]

[0022] According to the present invention, there is no special requirement to the kind of sulfonating agent, and various sulfonating agents in the prior art can realize the object of the present invention, considering that the sulfonating agent with strong acidity and strong oxidizing property can improve the yield of reaction rate, preferably, the sulfonating agent is sulfuric acid or oleum with a concentration of 95-102% by weight.

[0023] According to the present invention, in order to obtain acrylamide monomers in high yields, preferably, the reaction includes two stages carried out in sequence: the first stage is that the sulfur contacting agent with a...

Embodiment 1

[0054] This example is used to illustrate the acrylamide monomer and acrylamide copolymer provided by the present invention and the preparation method thereof.

[0055] (1) Preparation of acrylamide monomer

[0056] Add 530 grams of acrylonitrile into a temperature-controlled glass reactor, and slowly add 100 grams of concentrated sulfuric acid with a concentration of 98% by weight to the acrylonitrile under stirring, and cool the mixed solution to -5°C. After stirring evenly, slowly Add 72 grams of diisobutene to keep the temperature of the reaction system below 5°C. After reacting for 2 hours, an appropriate amount (0.064 mL) of water was added, and the reaction was continued for 2 hours at 25°C. After standing still, crystals precipitated. After filtering, washing and drying, the pure monomer was obtained and weighed to obtain a product yield of 93.8%.

[0057] (2) Preparation of acrylamide copolymer

[0058] In the reactor, add 1000 grams of acrylamide (14.069mol), 7.9...

Embodiment 2

[0060] This example is used to illustrate the acrylamide monomer and acrylamide copolymer provided by the present invention and the preparation method thereof.

[0061] (1) Preparation of acrylamide monomer

[0062] Add 1060 grams of acrylonitrile into the temperature-controlled glass reactor, and slowly add 117.6 grams of concentrated sulfuric acid with a concentration of 98% by weight to the acrylonitrile under stirring, cool the mixed solution to 5°C, and after stirring evenly, slowly add 72 grams of diisobutylene, maintaining the temperature of the reaction system below 10°C. After reacting for 4 hours, an appropriate amount (6.4 mL) of water was added, and the reaction was continued at 20° C. for 4 hours. After standing still, crystals precipitated. After filtering, washing and drying, the pure monomer was obtained and weighed to obtain a product yield of 92.0%.

[0063] (2) Preparation of acrylamide copolymer

[0064] In the reactor, add 1108.85 grams of AM (15.6mol)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com