Easy-to-open lid sheet coating

An easy-to-pull cover and sheet technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem of low gloss on single-coated surfaces and double-coated surfaces, ineffective protection of coatings, and unsatisfactory color rendering. and other problems, to achieve the effect of protective coating, guaranteeing purity and safety, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

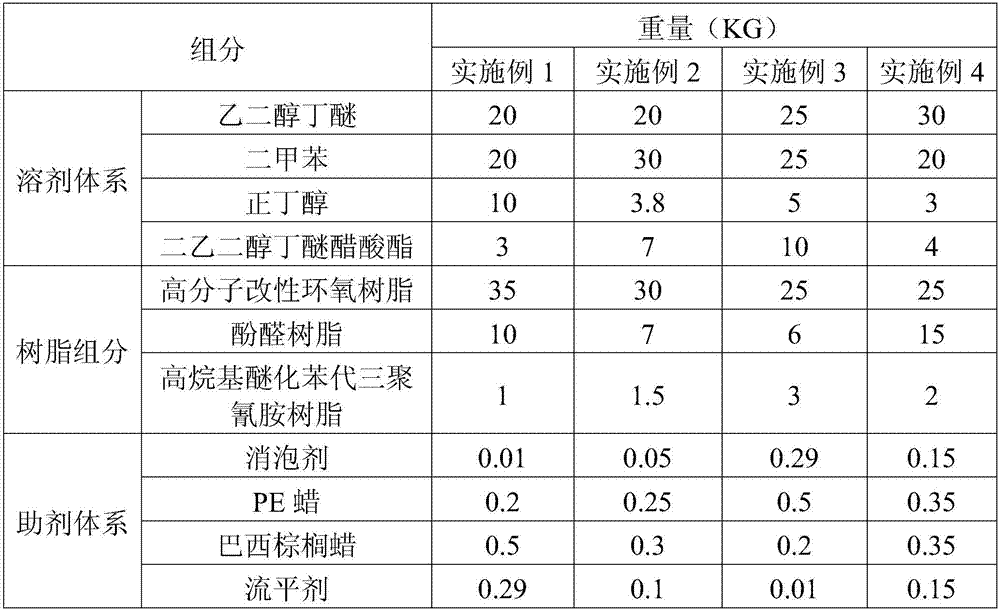

[0011] The raw materials used in embodiment 1-3 are as follows:

[0012]

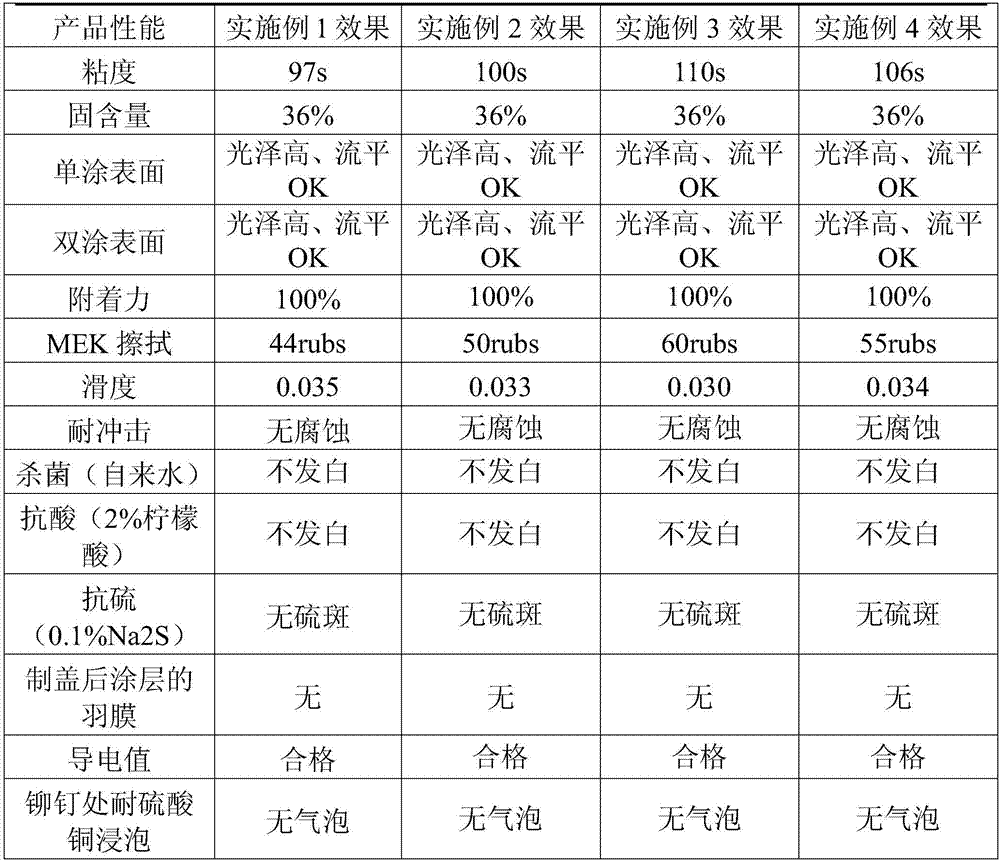

[0013] According to the performance comparison of the coating that embodiment 1-4 makes:

[0014]

[0015] In the above test performance, the test method of viscosity adopts GB / T1723-1993, Tu-4 cup, the test standard is 25°C, and the unit is second (s).

[0016] The slip test method is to use the ALTEK slip tester to test. The protective equipment used are protective glasses, canvas gloves and safety shoes. The specific steps are as follows:

[0017] 1. Bake the painted tinplate sheet or aluminum sheet and cool to room temperature;

[0018] 2. Check and adjust the horizontal position of the slip meter. Place the above sheets on the slip meter platform, with the paint film facing upwards, and press down the three fixing buckles;

[0019] 3. Put the sliding weight on the sheet, and the three spherical surfaces are in contact with the paint film. Connect the sliding weight to the drawbar with a hoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com