Graphene chip of sanitary towel

A technology of graphene and sanitary napkins, applied in the field of graphene sanitary napkin chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

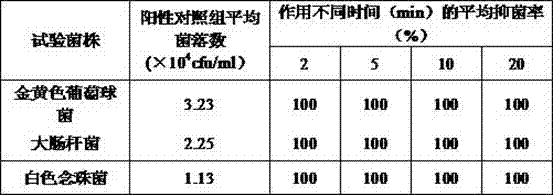

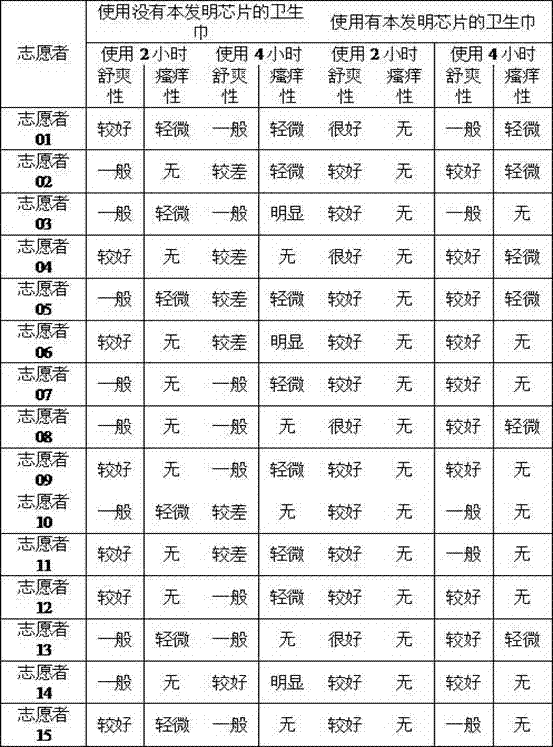

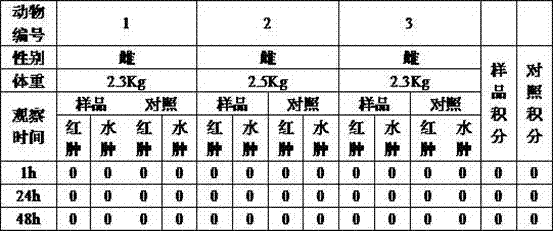

Examples

Embodiment 1

[0041] Add 71.35 parts of water to the stirring tank, then add 0.3 parts of hydroxyethyl cellulose and 0.3 parts of sodium alginate and stir until it is completely dissolved, then add 0.1 parts of NXZ defoamer, 0.4 parts of AG165 dispersant, and 0.05 parts of LXE fungicide and 0.2 parts of BEK-560 antifungal agent, and stir evenly, then add 2 parts of titanium dioxide, 0.1 parts of graphene, 0.5 parts of graphite powder and 0.2 parts of indium tin oxide, and slowly drop 0.5 parts of Texanol type film-forming agent, And stir to disperse evenly, finally add 8 parts of R-996AD emulsion and 15 parts of AP-5036 emulsion into the stirring tank, and slowly add 1 part of RM-8W thickener, stir evenly, the obtained liquid is Disperse the slurry; then apply the dispersed slurry evenly on the surface layer of the non-woven fabric according to the weight ratio of the dispersed slurry and the raw materials for producing non-woven fabrics at a ratio of 20:80, and rewind the non-woven fabric int...

Embodiment 2

[0043] Add 57.56 parts of water to the stirring tank, then add 0.6 parts of hydroxyethyl cellulose and 0.2 parts of sodium alginate and stir until it is completely dissolved, then add 0.3 parts of NXZ defoamer, 0.7 parts of AG165 dispersant, and 0.12 parts of LXE fungicide And 0.12 parts of BEK-560 antifungal agent, and stir evenly, then add 5 parts of titanium dioxide, 0.5 parts of graphene, 3 parts of graphite powder and 0.1 part of indium tin oxide, and slowly add 1.2 parts of Texanol type film-forming agent, And stir to disperse evenly, finally add 5 parts of R-996AD emulsion and 25 parts of AP-5036 emulsion into the stirring tank, and slowly add 0.6 parts of RM-8W thickener, stir evenly, the obtained liquid is Disperse the slurry; then apply the dispersed slurry evenly on the surface of the non-woven fabric according to the weight ratio of the dispersed slurry and the raw materials for producing non-woven fabrics at a ratio of 20:80, and rewind the non-woven fabric into A...

Embodiment 3

[0045] Add 42.1 parts of water to the stirring tank, then add 1 part of hydroxyethyl cellulose and 0.1 part of sodium alginate and stir until it is completely dissolved, then add 0.5 parts of NXZ defoamer, 1 part of AG165 dispersant, and 0.2 parts of LXE fungicide and 0.05 parts of BEK-560 antifungal agent, and stir evenly, then add 8 parts of titanium dioxide, 1 part of graphene, 5 parts of graphite powder and 0.05 parts of indium tin oxide, and slowly add 2 parts of Texanol type film-forming agent, And stir to make it evenly dispersed, finally add 3 parts of R-996AD emulsion and 35 parts of AP-5036 emulsion into the stirring tank, and slowly add 1 part of RM-8W thickener, stir evenly, the obtained liquid is Disperse the slurry; then apply the dispersed slurry evenly on the surface of the non-woven fabric according to the weight ratio of the dispersed slurry and the raw materials for producing non-woven fabrics at a ratio of 20:80, and rewind the non-woven fabric into Appropr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com